Writing in the journal Materials, a team of scientists from China, Ukraine, and Poland has investigated how to better freeze small, loose food items. The authors have stated that achieving this will improve efficiency and reduce the cost of freezing food items.

Study: Ways to Improve the Efficiency of Devices for Freezing of Small Products. Image Credit: leonori/Shutterstock.com

The Importance of Efficient Food Freezing

Fruit and vegetables are vitally important for human diets due to their nutritional profiles. Freezing these products is the preferred method of long-term storage due to nutrient retention and the impedance of microbial growth at extremely low temperatures. Another antimicrobial benefit is the conversion of water into ice, which reduces the water activity of food.

Ice crystal formation, depending on the size of the crystals formed, can have varying effects on the freezing process of plant cells. Studies have been performed on improving freezing technologies. Rapid freezing technologies have progressed in recent decades to avoid creating quality issues during product manufacture. One process for freezing fruit such as strawberries is to use perforated stainless-steel containers, which not only speed up the freezing process but also allow for improved hygiene and ease of cleaning equipment between uses.

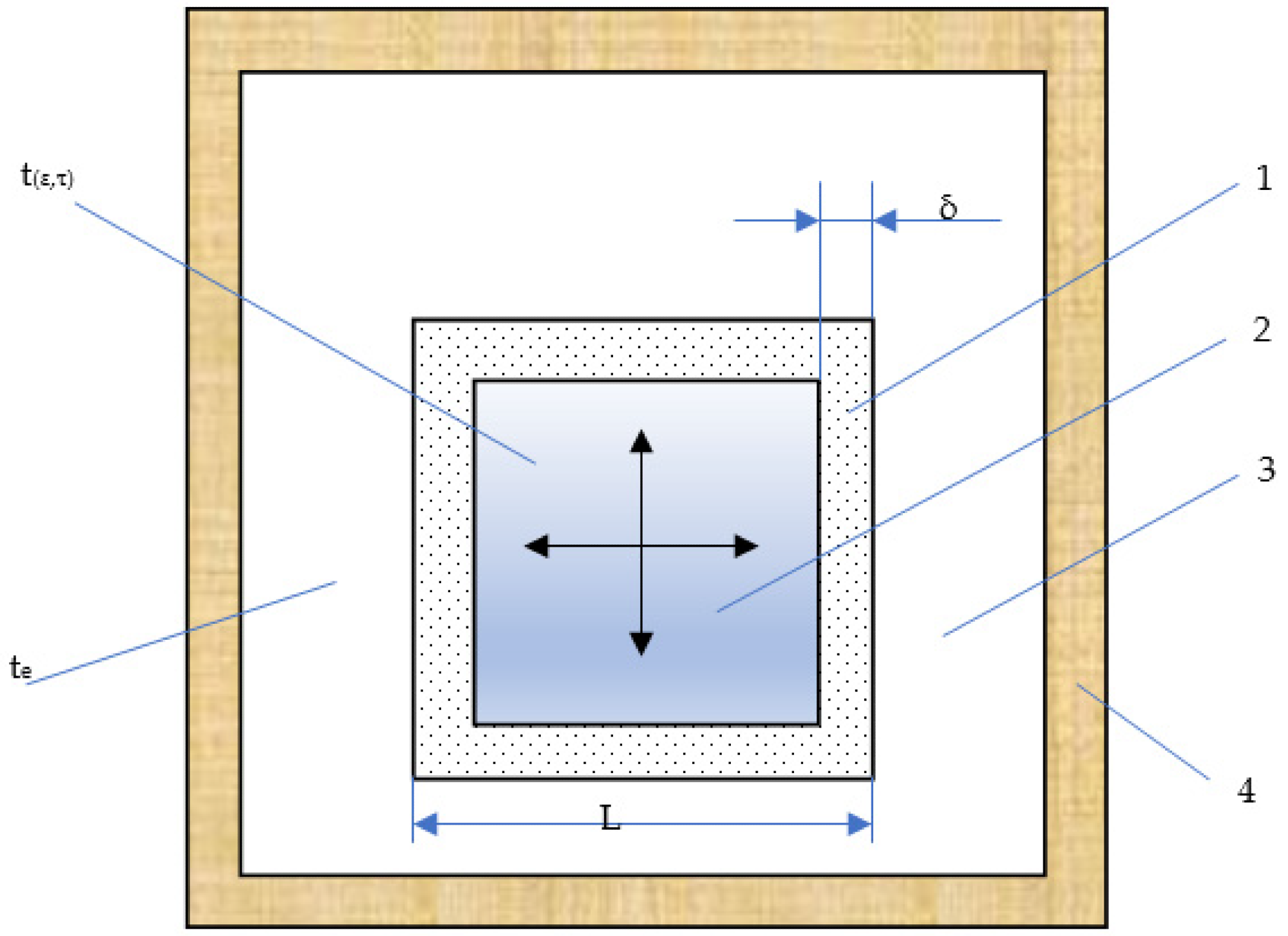

Product cube freezing model: 1—frozen layer, 2—layer of the product that will be frozen, and which has an initial temperature, 3—cooling air, 4—thermal insulation of a mechanized device for small-piece freezing. Image Credit: Bazaluk, O et al., Materials

One of the main problems during the freezing process is the formation of blocks by food sticking together. This can be overcome by including small berries, fruits, and vegetables which function as a fluidized bed to improve airflow. However, using fans during this process increases energy consumption. Therefore, there is an urgent need to improve the separation efficiency of the freezing process to reduce energy costs. Additionally, quality issues can occur during the freezing process due to mechanical factors, with foodstuffs coming into contact with each other and the machinery.

The inefficiency of existing devices and processes has been highlighted in several studies, which have proposed various strategies to overcome current challenges. Considerable attention has been paid in research to the thermochemical aspects of the freezing process. Some studies have suggested pre-freezing fruits and berries in a layer to prevent quality issues during freezing. Other studies have proposed using fluidization devices.

Analytical and experimental studies have been conducted in the past few decades into improving rapid freezing processes, but there has been a notable lack of comparative studies on energy consumption between different mechanical quick-freezing and fluidization methods. Fluidization uses cold airflow to freeze food, whereas mechanical and pseudo-fluidizing methods fluctuations in the machinery’s working surface constantly move the product.

The Study

The research published in Materials has investigated improving the efficiency of devices used in the food industry for freezing small food products such as berries, fruits, and vegetables.

The authors have developed an algorithm for calculating energy costs for both mechanical shaking and fluidization methods. They compared the results of calculations for both processes to demonstrate which was more energetically beneficial. The authors performed several calculations to elucidate relevant information for comparing the two processes and their energy efficiency.

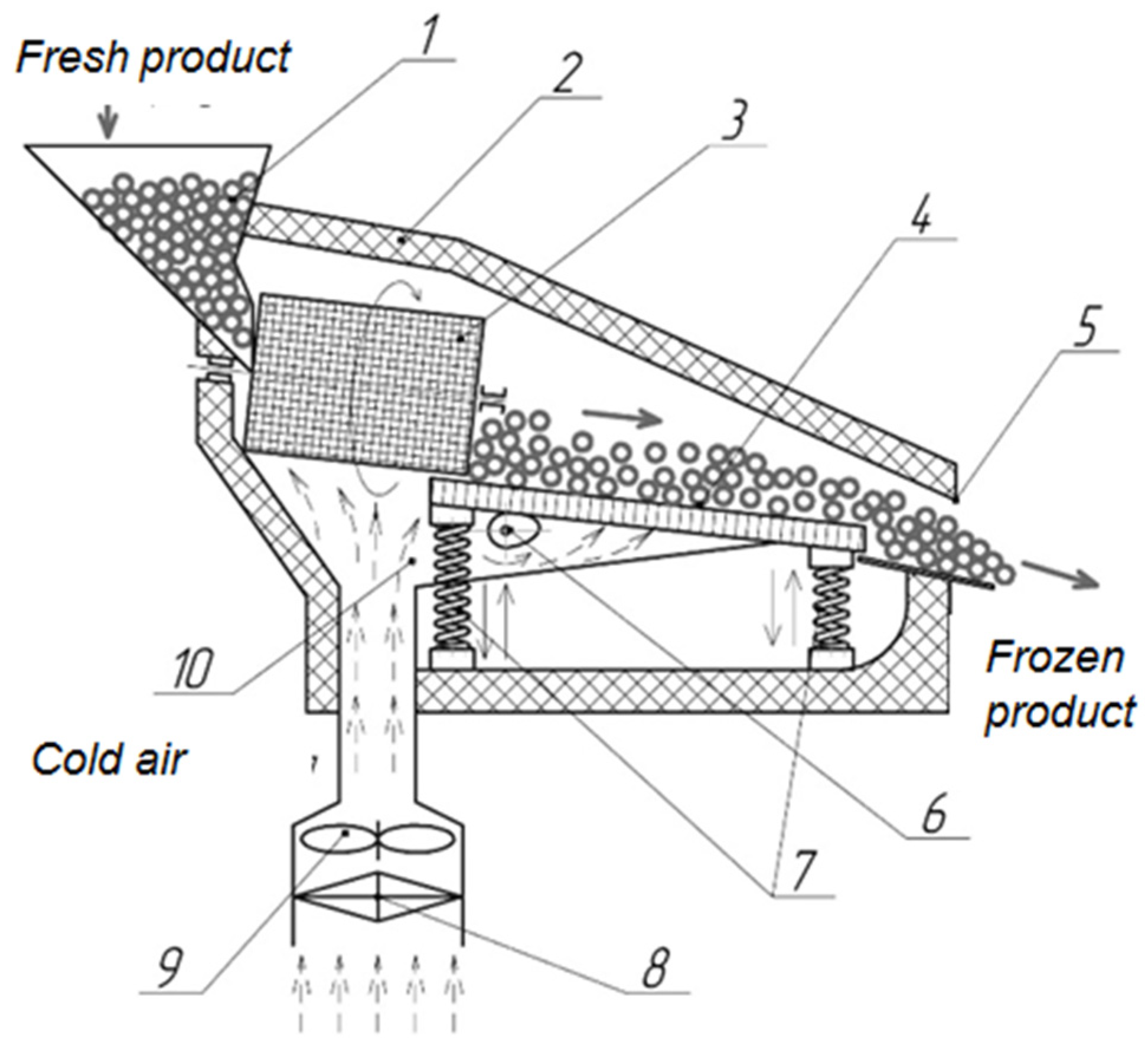

Functional scheme of the cascade freezer; 1—download block, 2—thermally insulated chamber, 3—a rotating hollow inclined drum made of mesh, 4—mesh conveyor, 5—unloading window, 6—eccentric mechanism, 7—springs, 8—evaporator of the refrigeration unit, 9—fan, 10—distribution channels of low temperature air. Image Credit: Bazaluk, O et al., Materials

Additionally, the influence of the thickness of the freezing layer on the amount of heat removal during preliminary freezing was investigated by the authors. The minimum thickness of this layer to ensure lack of adhesion between food products was determined to be 0.4-0.9 mm. Blocks of squash were used to determine this freezing quality parameter.

The authors designed and patented a cascade freezer, with its design optimized based on the results of their analyses. This equipment consists of several components, including a downward block, a thermally insulated chamber, a rotating hollow mesh inclined drum, an unloading window, an eccentric mechanism, springs, an evaporator, a fan, and distribution channels for circulating cold air.

The advantage of cascade freezing is the prevention of adhesion and enhanced damage protection for delicate foodstuffs such as fruit and sliced vegetables. In a cascade freezing device, the product is continuously mixed and cooled to extremely low temperatures by a continuous low-temperature airflow which freezes the product’s surface layer. This facilitates further preparation in conventional refrigeration equipment without the associated quality issues.

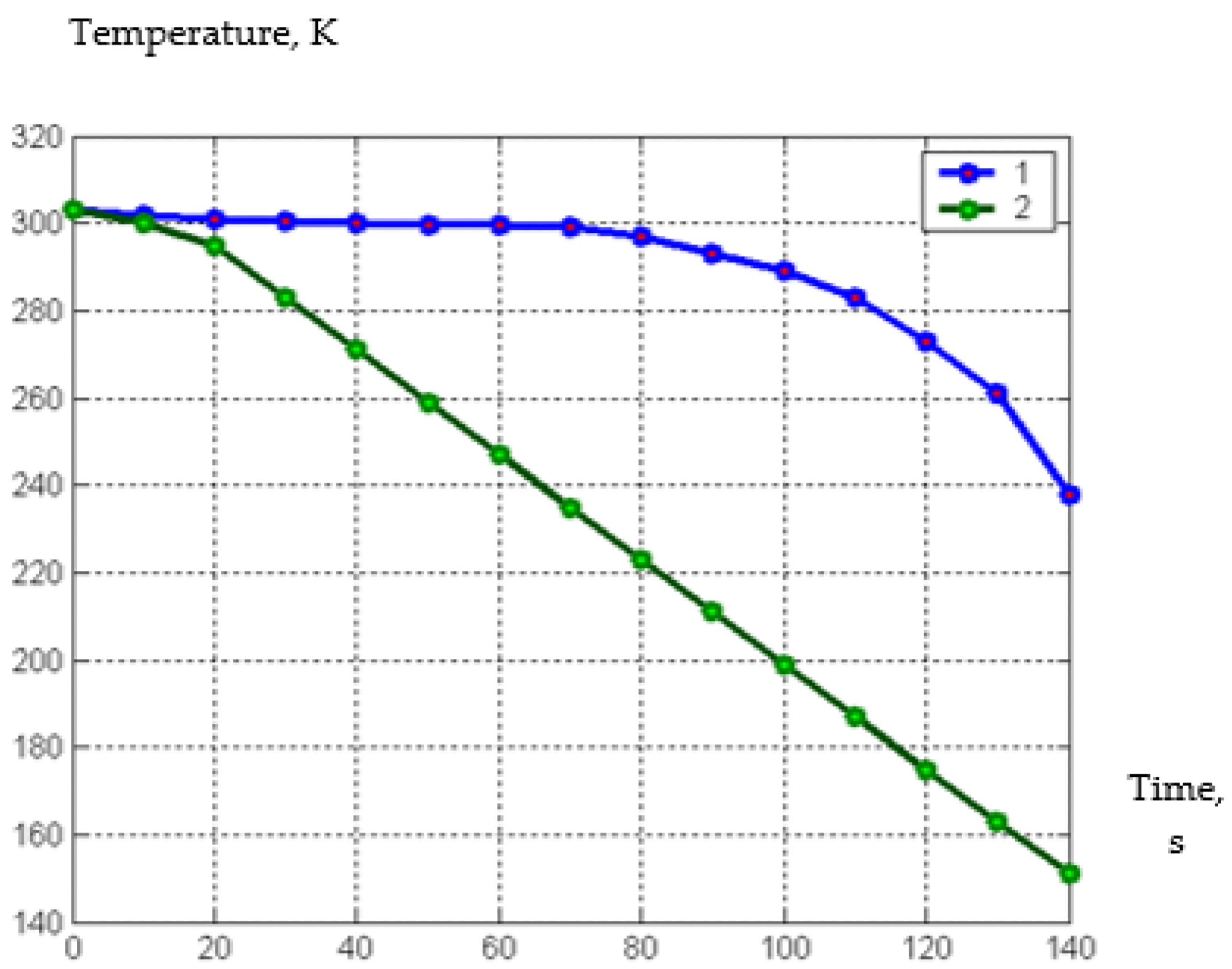

The temperature (K) dependence of freezing of squash pieces on time (s) with a freezing agent in nitrogen vapor and in liquid nitrogen; 1—freezing pieces of squash in nitrogen vapor, 2—freezing pieces of squash in liquid nitrogen. Image Credit: Bazaluk, O et al., Materials

Freezing time for berries, fruits, and vegetables in the patented cascade device was less than conventional techniques, at a period of only 5-10 minutes. This provides distinct advantages in terms of energy consumption. The authors stated that this time could be reduced using different refrigerants to air, and for this purpose, they investigated liquid nitrogen and nitrogen vapors.

Results of the analysis and experiments in the research demonstrated that the author’s methodology for determining energy costs during cascade freezing and the design parameters can be used in future studies. Overall, the authors have presented a methodology and device that can significantly improve the efficiency of rapid freezing and retain the quality that is lost using conventional techniques.

Further Reading

Bazaluk, O et al. (2022) Ways to Improve the Efficiency of Devices for Freezing of Small Products [online] Materials [online] 15(7) 2412 | mdpi.com. Available at: https://www.mdpi.com/1996-1944/15/7/2412

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.