By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 29 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 29 2022In an article recently published in the open-access journal Materials, researchers investigated the flammability of firefighter protective clothing.

Study: Investigation of Flammability of Protective Clothing System for Firefighters. Image Credit: Shaun Jeffers/Shutterstock.com

Background

The most significant function of a garment is to shield the human body from external elements. Firefighting has become one of the most dangerous jobs in the world. This is why their clothing should be such that it can protect the firefighter against extremes temperatures, flames, rain, cold, reactive chemicals, mechanical action, health-hazardous compounds, and so on. In collaboration with designers, firemen, and engineers, functional protective apparel against flame and heat should be designed. So far, new types of fire-resistant and high-performance fibers with unique features have been created by using microporous materials, allowing protective gear to last longer and be easier to care for while still providing enough safety and protection.

Various methodologies to characterize fire-resistant textile materials have recently been tested. Wearing thick or multilayer textile materials can give high thermal protection for firefighter clothing systems, and it is well recognized that the performance of every layer of a firefighters' protective gear has a substantial impact on the level of protection supplied. It's still unclear how damaging various exposures are and for how long the firefighting protective equipment could continue to protect to an appropriate level when it is exposed to high temperatures and direct fire or flame.

Tested underwear on a fire manikin. Image Credit: Šajatovic, A. H et al., Materials

About the Study

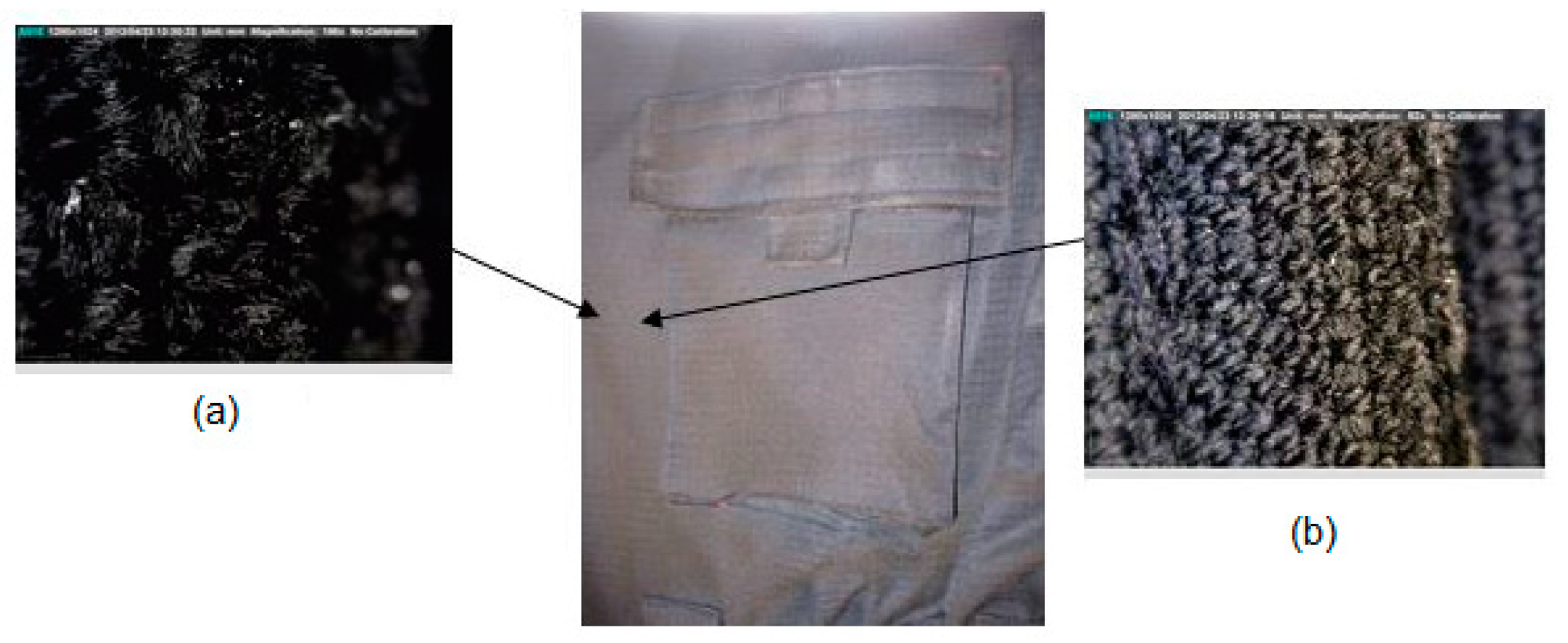

In this study, the authors used a fire manikin to conduct research on a garment system for heat and flame protection, and subsequently analyzed the damage produced after testing. A USB Dino-Lite microscope was used to evaluate the presence of microdamage and contaminants on the garment system as part of the damage study. During the thermogravimetric (TG) analysis of samples, the intensities and composition of gaseous decomposition products were also studied.

The researchers investigated a protective garment system comprised of carefully selected materials. The underwear was constructed of a wool/modacrylic combination in a 70%:30% ratio, which added to good protection and comfort through synergy. In order to provide great heat and flame resistance as well as thermophysical comfort, the overalls were fashioned of a 55%:45% blend of modacrylic and cotton.

The team evaluated firefighting overalls constructed of cotton/modacrylic fabric material on a fire manikin, focusing on their mechanical qualities. An examination of damage following fire exposure and the fabric's thermal properties were also depicted.

The flammability features of the clothing system for heat and flame protection were researched, and the damage that occurred to the overalls designed for firefighters to extinguish forest fires was analyzed following testing with a fire manikin. On the fire manikin, a clothing system comprising of underwear made of 30% modacrylic fiber and 70% wool fiber, as well as overalls made of 45% cotton fiber and 55% modacrylic fiber were used for protection against flame and heat to suppress forest fires.

Damage in the area of the upper pocket of the overalls made with a Dino-Lite microscope in two different magnification: (a) 184×; (b) 60×. Image Credit: Šajatovic, A. H et al., Materials

Observations

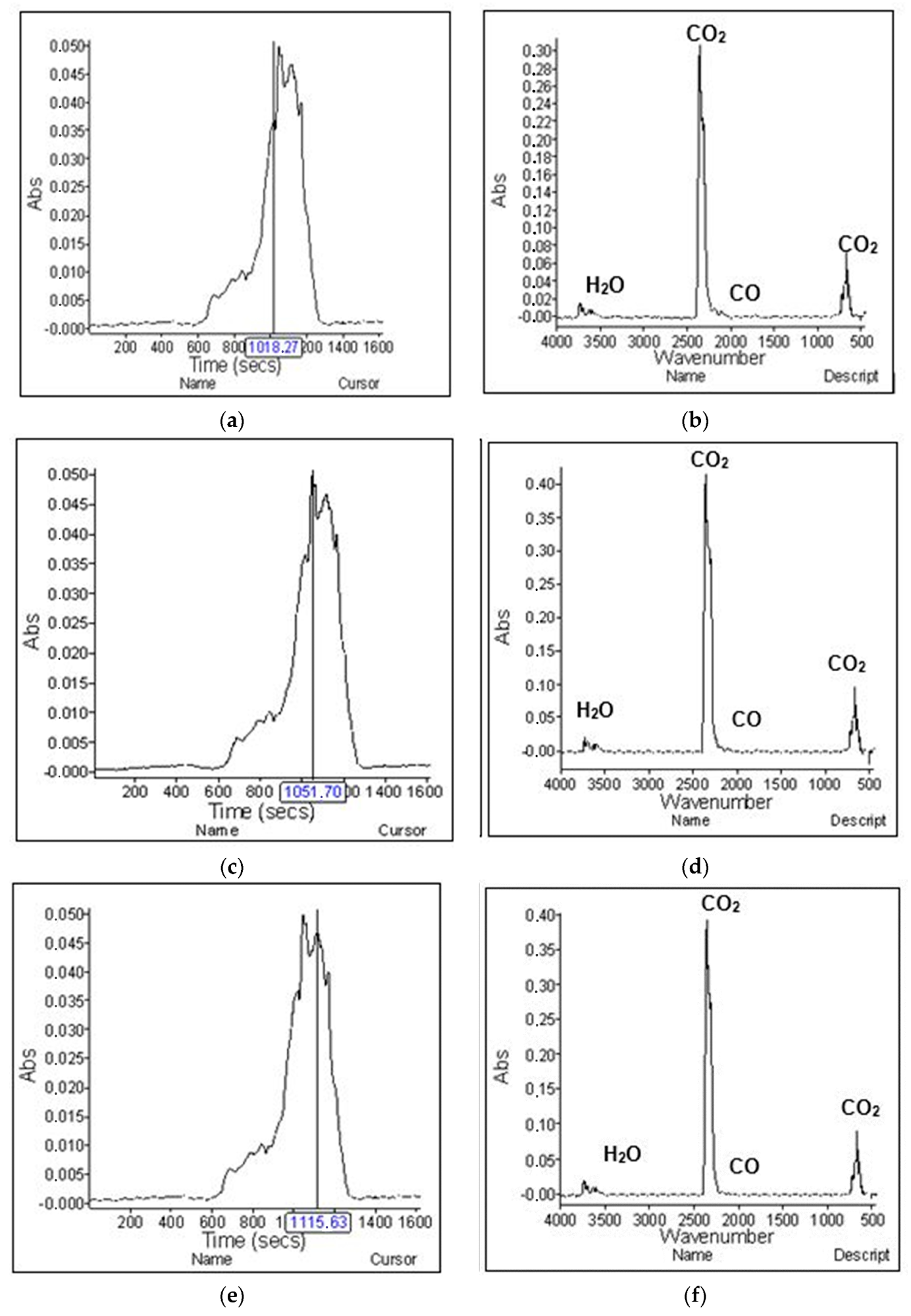

The fabric before exposure to fire (sample 1) had a specific heat release capacity of 34.67 J(g.K)-1 and the fabric after exposure to fire (sample 2) had a specific heat release capacity of 45.33 J(g.K)-1. At 509.13 °C, the first intense absorption peak was discovered.

CO2 having typical highest points at 2322 and 2359 cm-1, CO with characteristic highest points at 2110 and 2179 cm-1, and water with characteristic highest points at 1550 to 1566 cm-1 and 3500 to 4000 cm-1 were identified as evaporative breakdown products. The second and third intense absorption peaks were detected at 525.85 and 557.82 °C, respectively.

The results demonstrated that the user of the tested garment system had not suffered injuries that were dangerous to their health or life, which confirmed the protective capabilities of the proposed fabric. The TG and Fourier transform infrared (FTIR) results showed that the decomposition of the fabric sample of the modacrylic–cotton fiber blend occurred in three phases, with CO2, H2O, and CO as the recognized gaseous degradation products.

TG-IR analysis of sample. (a) The first intense absorption spectrum; (b) measured gases on IR at a temperature of 509.13 °C: (c) second absorption spectrum; (d) measured gases on IR at a temperature of 525.85 °C; (e) third absorption spectrum; (f) measured gases on IR at a temperature of 557.82 °C. Image Credit: Šajatovic, A. H et al., Materials

Because of the sufficient usage of fire-resistant undergarments, the tested clothing system provided a good level of protection. The results of testing on a fire manikin demonstrated that while utilizing such a garment system, the user would not suffer tissue damage, which could represent a health or life hazard if they were removed from the fire and heat immediately.

Conclusions

In conclusion, this study elucidated that the use of a fire manikin and an explosive fire simulator substantially aids in predicting the severity of burns and the likelihood of survival of users of the clothing systems. The thermal characteristics of the protective firefighting clothing system were reduced after exposure to thermal manikin testing as compared to the starting material.

The authors emphasized that all of the materials used are fireproof so that the failure does not harm the users' health or lives. They also believe that the collaboration of experts in the field of materials and fibers, designers, constructors, and technologists, as well as end-users and manufacturers of protective clothing, is required in the design and production processes of protective clothing systems.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Šajatovic, A. H., Grgac, S. F., Zavec, D., Investigation of Flammability of Protective Clothing System for Firefighters. Materials 15(7) 2384 (2022). https://www.mdpi.com/1996-1944/15/7/2384