A research group headed by Prof. Jin Zhu from the Chinese Academy of Sciences’ Ningbo Institute of Materials Technology and Engineering, in collaboration with Prof. Jing Chen at NIMTE and scientists at Tsinghua University, proposed a simple method for developing antibacterial lignin-based polyurethane/silver (Ag) composite foam that aids wound healing as wound dressings.

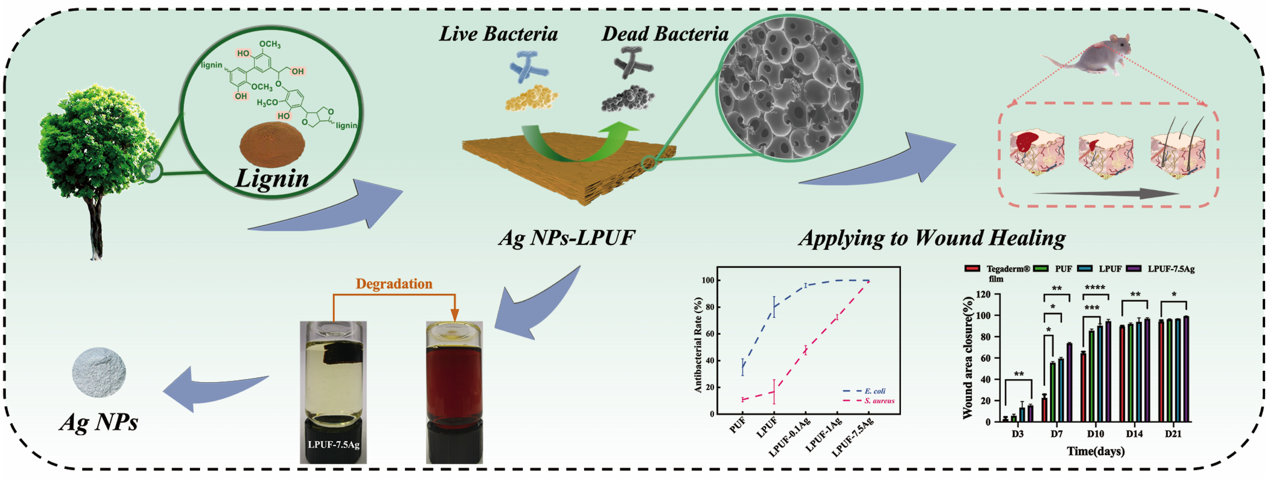

The synthesis and application of lignin-based polyurethane/Ag composite foams. Image Credit: Ningbo Institute of Materials Technology and Engineering.

The synthesis and application of lignin-based polyurethane/Ag composite foams. Image Credit: Ningbo Institute of Materials Technology and Engineering.

The study’s findings were published in the Biomacromolecules journal.

Excessive exudate absorption and wound infection prevention are both important for tissue repair, making antibacterial wound dressing crucial. The use of polyurethane materials in wound dressings has garnered a lot of attention around the world as an excellent strategy to make high-performance antibacterial wound dressings.

Traditional polyurethane foams’ efficacy in biomedical applications has been limited due to their reliance on petroleum resources, lack of antibacterial activity and complicated preparation process.

The researchers created lignin-based polyurethane foam as a new biomass wound dressing using a simple one-step foaming and in situ reduction method, with a minuscule fraction of silver nanoparticles (i.e., Ag NPs) loaded on the skeleton of the composite foam.

The natural compound lignin, which has metal-reducing properties, was used as a reducing agent to reduce silver ions to Ag NPs in situ during the polyurethane production process.

The developed antibacterial lignin-based polyurethane/Ag composite foam had improved mechanical, thermal and antibacterial properties, as it almost completely (99%) inhibited the growth of Escherichia coli within 1 hour and Staphylococcus aureus within 4 hours, respectively, thanks to its open porous structure.

Furthermore, tests on mice revealed that the synthesized foam dressing efficaciously promoted new tissue generation and collagen deposition in full-thickness skin wounds, facilitating wound healing.

The current research sheds light on how biological antibacterial polyurethane dressings are developed. The high-performance antibacterial lignin-based composite foam that was developed has huge potential for mass production and clinical use.

The current study was funded by the National Key Research and Development Program of China, the OCE Project #29983 (Canada), the National Natural Science Foundation of China, etc.

Journal Reference:

Li, S., et al. (2022) Antimicrobial Lignin-Based Polyurethane/Ag Composite Foams for Improving Wound Healing. Biomacromolecules. doi.org/10.1021/acs.biomac.1c01465.