Researchers from China have reported the development of robust bio-based hybrid aerogels using green synthesis methods which possess superior mechanical flexibility and dimensional stability, with potential uses for sound absorption. Their findings have been published online in the journal Polymers.

Study: Enhanced Toughness and Sound Absorption Performance of Bio-Aerogel via Incorporation of Elastomer. Image Credit: Vink Fan/Shutterstock.com

Using Aerogels for Sound Absorption

Rapid urbanization, industrialization, and the growth in transportation have increased the level of noise that human and animal populations experience. Noise pollution has been highlighted as a major cause of health problems and deleterious effects on urban dwellers, and therefore the need to reduce it is a key concern in materials science and governmental regulatory bodies.

Porous materials such as aerogels and foams can effectively absorb sound energy due to the presence of multiple channels within them. Whilst they are highly effective for this purpose, many conventional foams are prepared using non-renewable fossil fuels and are non-biodegradable. Common types of commercial noise reduction foam include melamine foam and polyurethane foam.

The need for more sustainable materials and the issues with rapidly diminishing natural resources has facilitated the need for renewable sources of materials that additionally can help mitigate greenhouse gas emissions. Bio-based aerogels have recently emerged as attractive candidates for sound absorption applications.

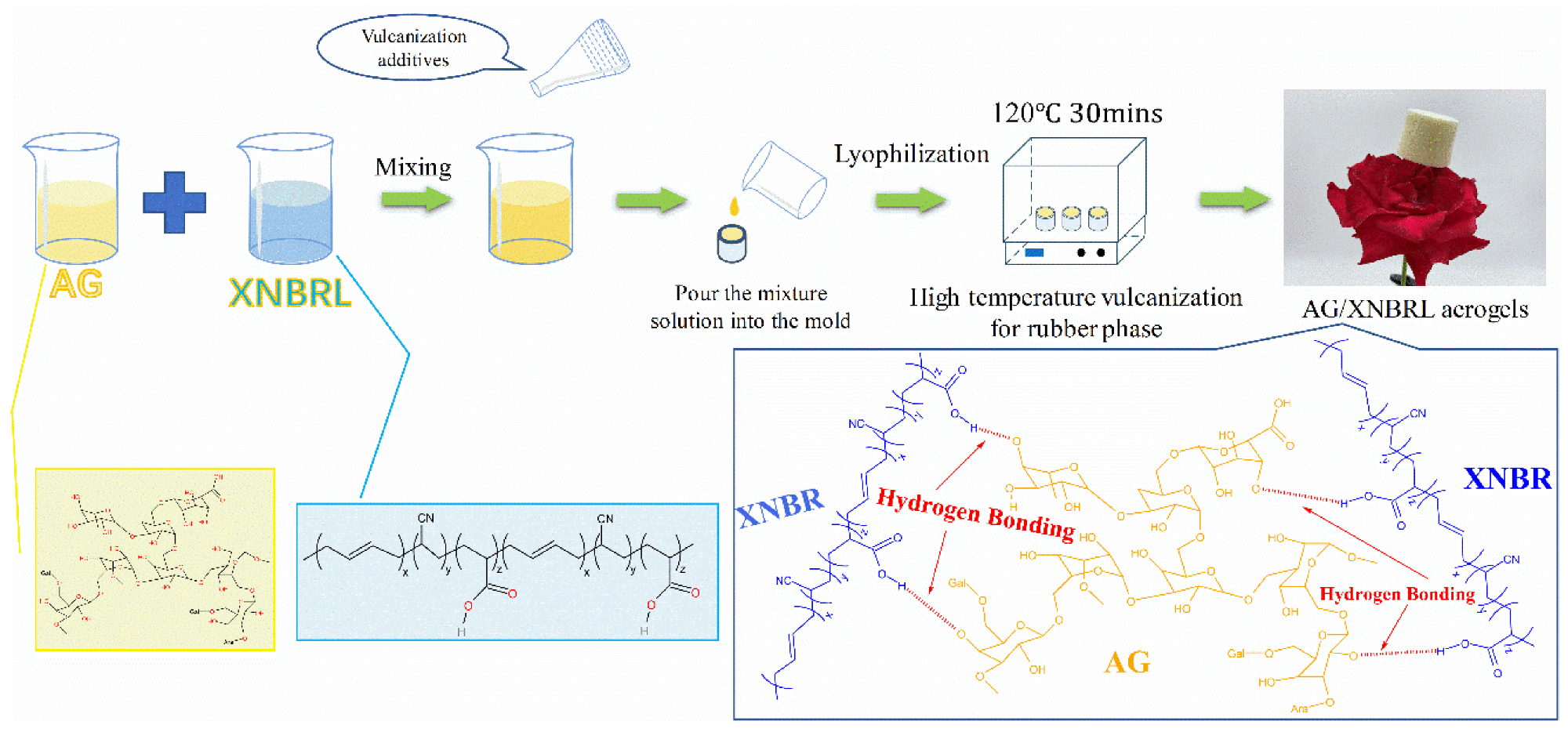

Schematic diagram of the preparation route for AG/XNBRL aerogel. Image Credit: Shen, J et al., Polymers

Bio-Based Aerogels

Aerogels are synthesized by removing liquid from a gel using supercritical drying. This leaves behind an extremely light, low density, highly porous material with superior properties such as electrical and thermal insulation and good mechanical strength. Aerogels are the lightest class of synthetic materials and have been used in a multitude of industrial applications since their invention in 1931. Nicknames for aerogels include frozen smoke and solid air.

Silica aerogels have been widely studied for commercial applications due to their unique physiochemical properties, but these aerogels have limitations in terms of high mechanical fragility. Due to the need to develop aerogels with high performance, biopolymers have been explored in recent years as materials for aerogel synthesis. Variants of biopolymer-based aerogels studied recently include cellulose aerogels, lignin aerogels, and chitosan aerogels.

However, using bio-based aerogels for sound absorption purposes is still a new area of research, and their potential has still not been fully explored by scientists. Indeed, many bio-based aerogels still have problems with mechanical fragility, facilitating the need to use approaches such as cross-linking and incorporating fillers to improve their performance.

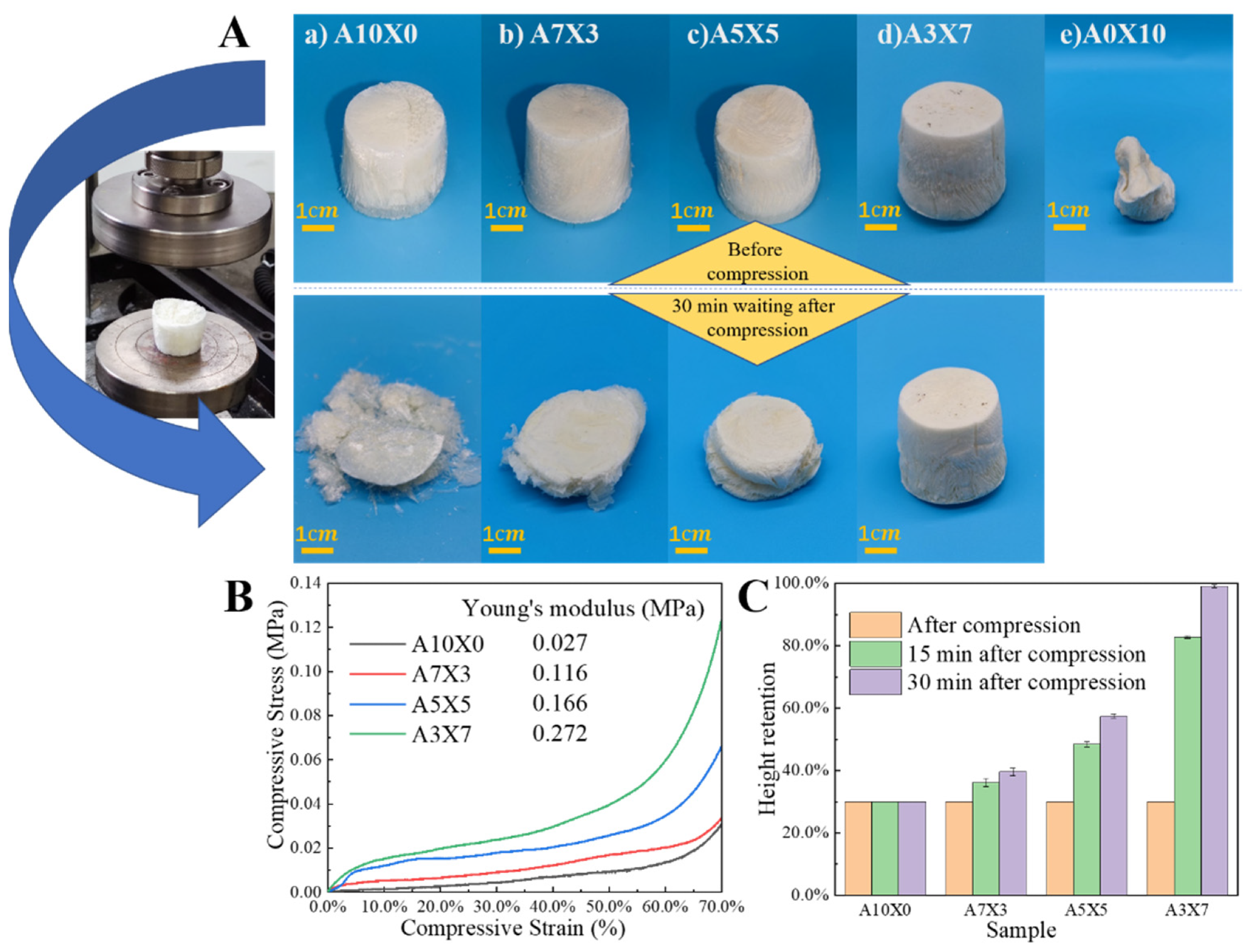

Mechanical performances for the AG/XNBRL aerogels. (A) Photos for AG/XNBRL aerogels before compression (upper panel) and 30 min waiting after compression (lower panel). (B) Compression curves of AG/XNBRL aerogels. (C) Height recovery of the samples after compression with various waiting times. Image Credit: Shen, J et al., Polymers

The Study

In the study, researchers from China have explored the development of improved bio-based aerogels for sound absorption applications. In the research, Arabic gum has been used as a material for aerogels by the authors.

Arabic gum is an abundant, inexpensive polysaccharide that is used for numerous commercial products in sectors such as the packaging, food, and textiles industries. This resource is harvested commercially from the Acacia seyal and Acacia Senegal trees. Its precise structures are not completely known, but it is a mixture of hydroxyproline protein and arabinogalactan polysaccharide.

An important characteristic of the prepared Arabic gum-based aerogels is the incorporation of elastomers. The specific elastomer used by the researchers is carboxylic butadiene-acrylonitrile latex, a commercially available rubber. Using the elastomer improves the toughness of the aerogel. Both Arabic gum and carboxylic butadiene-acrylonitrile latex are polar materials, which improves their compatibility.

In the research, a green synthesis method was used to prepare the elastomer-toughened Arabic gum bio-based aerogel, a combination of latex compounding and vacuum freeze-drying. This mitigates the environmental impact of the synthesis process, facilitating sustainable manufacturing, which can improve the sound absorption industry’s environmental friendliness.

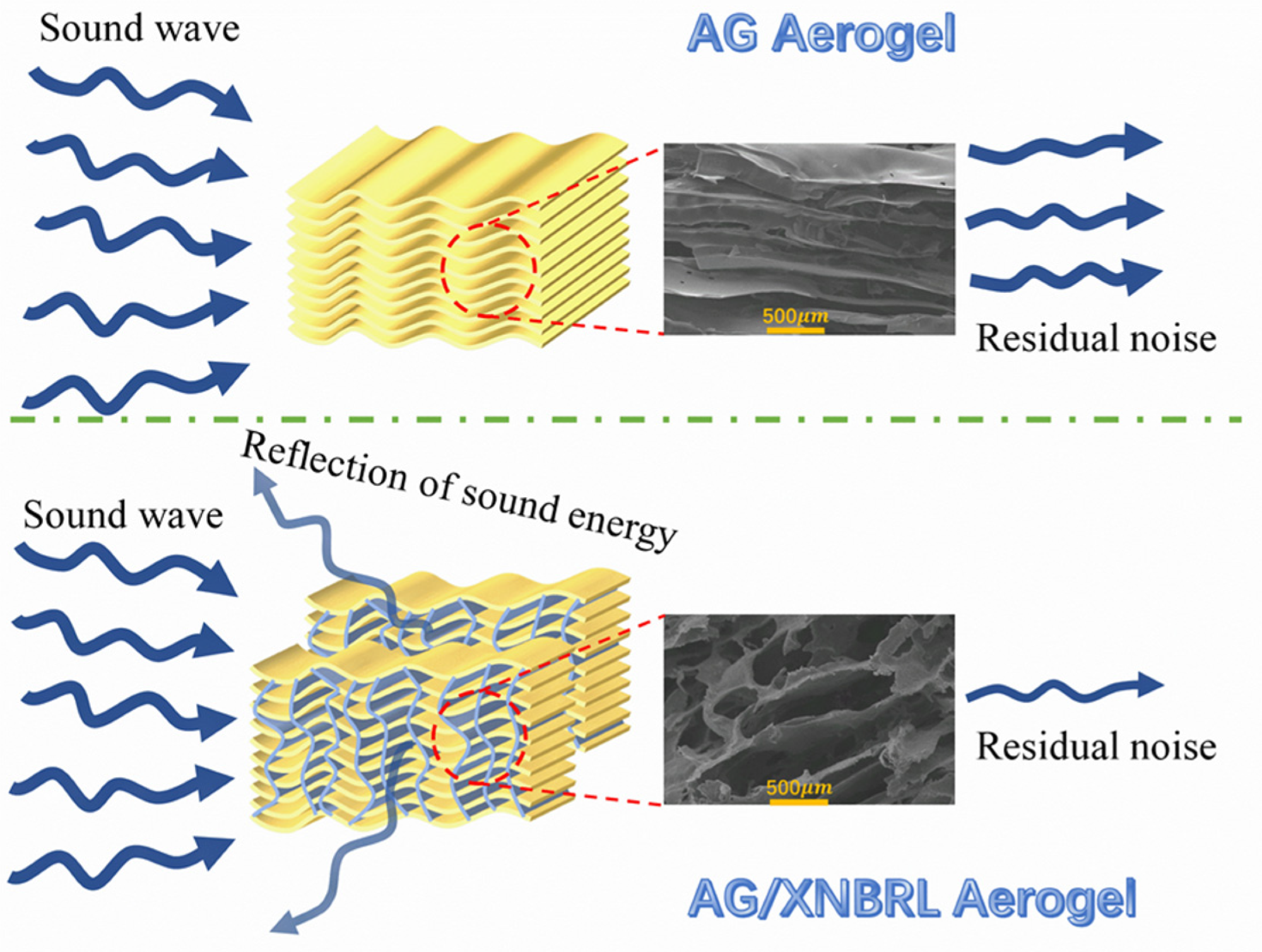

Sound absorption mechanism of AG aerogels and AG/XNBRL composite aerogels. Image Credit: Shen, J et al., Polymers

The authors used scanning electron microscopy to characterize the aerogel’s properties, along with mechanical analysis, thermogravimetric analysis, and testing of the material’s sound absorption performance. Analysis results revealed that the prepared aerogels exhibited enhanced toughness, thermal stability, and sound absorption due to the incorporation of carboxylic butadiene-acrylonitrile latex.

Arabic gum acted as a skeleton for the aerogel to improve its dimensional stability. The prepared Arabic gum/elastomer aerogel possessed a honeycomb-like morphology, which extended the travel path for sound waves, thereby creating multiple frictions and reflections in the material, which enhanced the sound absorption capabilities of the prepared hybrid aerogel.

Overall, the authors have demonstrated a novel aerogel that is based upon Arabic gum with incorporated elastomers to improve the mechanical, physical, and sound absorption properties of the prepared material. The authors have stated that their research and methods shed light on a promising design strategy for advanced hybrid aerogels for use in sound absorption. Whilst further research will be needed, this material has huge potential for reducing noise levels in urban areas, a common and harmful aspect of modern society.

Further Reading

Shen, J et al. (2022) Enhanced Toughness and Sound Absorption Performance of Bio-Aerogel via Incorporation of Elastomer [online] Polymers 14(7) 1344 | mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/7/1344

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.