By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Apr 12 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Apr 12 2022In an article recently published in the open-access journal Materials, researchers presented an eco-design of the cutting process of aluminum bronze.

Study: Ecodesign of the Aluminum Bronze Cutting Process. Image Credit: Labebe/Shutterstock.com

Background

The steady rise in energy use and costs has resulted in a significant increase in product manufacturing costs. As a result, numerous studies on the consumption of energy from machine tools to achieve certain products have been published. It has been shown that the lowest energy consumption may be achieved under situations where ideal cutting process parameters and suitable functional geometry are established.

A lot of research has been carried out on the potential of lowering energy consumption in the process of cutting various materials, but there are still some materials for which no viable solutions exist to ensure the ideal processing conditions.

Aluminum alloys are difficult to cut and consume a lot of energy. The adherence of the machined material to the active surfaces of the tool used in machining is a major issue in aluminum bronze machining. Cutting tool design that ensures a reduction in energy consumption is a major goal of cutting processing research. Given the complexity of the cutting operations, it is important to implement certain requirements for the production process itself that allow for the optimization of energy usage.

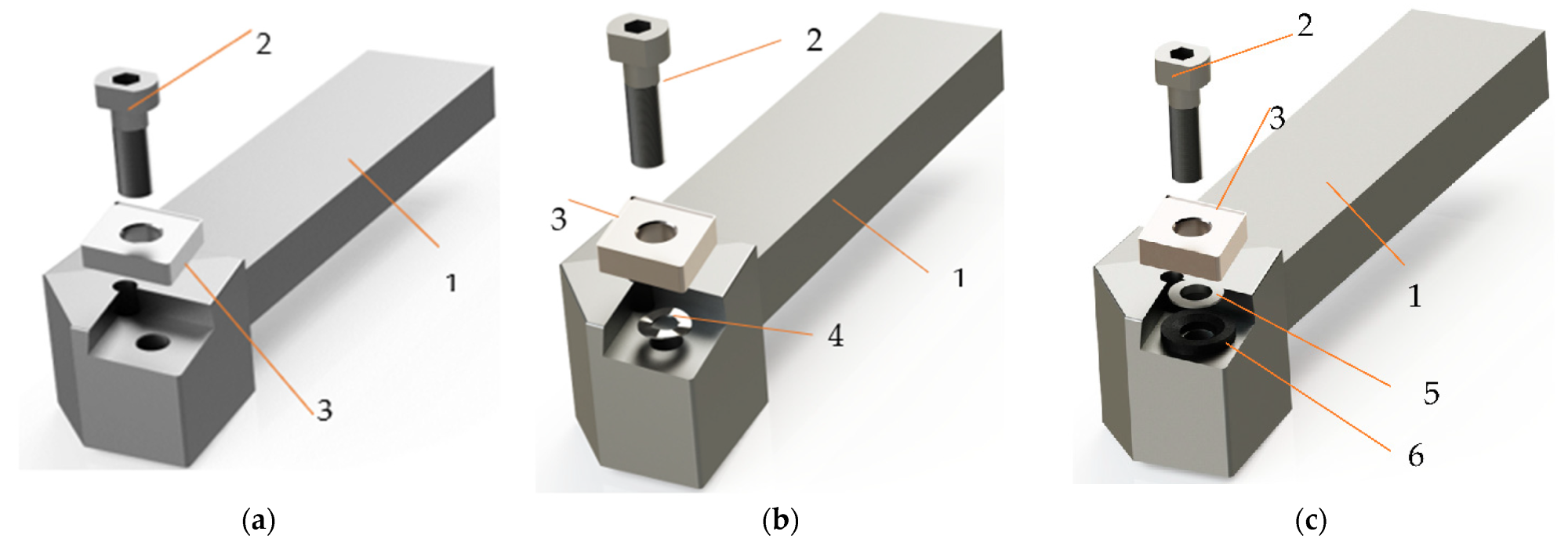

Tools for longitudinal turning: (a)—in the classic version (V01); (b)—with improved constructive form with a spring washer (V02), (c)—with improved constructive form with two spring washers (V03), 1—knife body; 2—screw fixing; 3—removable plate, 4—spring washer, 5—spherical washer, 6—spherical washer holder. Image Credit: Dobrotă, D et al., Materials

About the Study

In this study, the authors discussed the manufacturing of an aluminum bronze (C62300) semi-finished product with a diameter of Ø = 20 mm. Relationships between the quantity of power utilized and the quality of the surfaces sliced were discovered. The forces in the three directions i.e., Fc; Ff; Fp, relevant to the cutting process for three tool construction variants were measured. The cutting force values were monitored in three directions.

The processed surface roughness was measured to determine if there was a correlation. The experimental data were analyzed with the STATISTICA program in order to make a more complete examination of the link between the roughness and the forces.

The researchers determined the ideal machining conditions for aluminum bronze in order to achieve the lowest energy consumption and highest quality of treated surfaces. The experiments were carried out using a numerically controlled lathe (CNC). The machining was conducted with a longitudinal turning tool. The cutting tools used in processing were obtained using a tool body with a 20 mm x 20 mm section. In addition, a plate SNMG 12 04 12-PMC - Sandvik Coromant was used to equip the cutting tool body.

The team demonstrated how the cutting forces changed when the functional shape of the cutting tool was varied during the turning process. The forces were measured using a piezo-capacitive force sensor, which could measure in both quasi-static and dynamic modes. For calibration, traction-compression test equipment was used. The electrical signal from the force sensor was sent to the digital charge amplifier through a low-noise wire. The acquisition system's Catman software package was utilized to process, gather, and measure the force. The methodology to reduce energy usage and simultaneously maintain acceptable surface quality was illustrated.

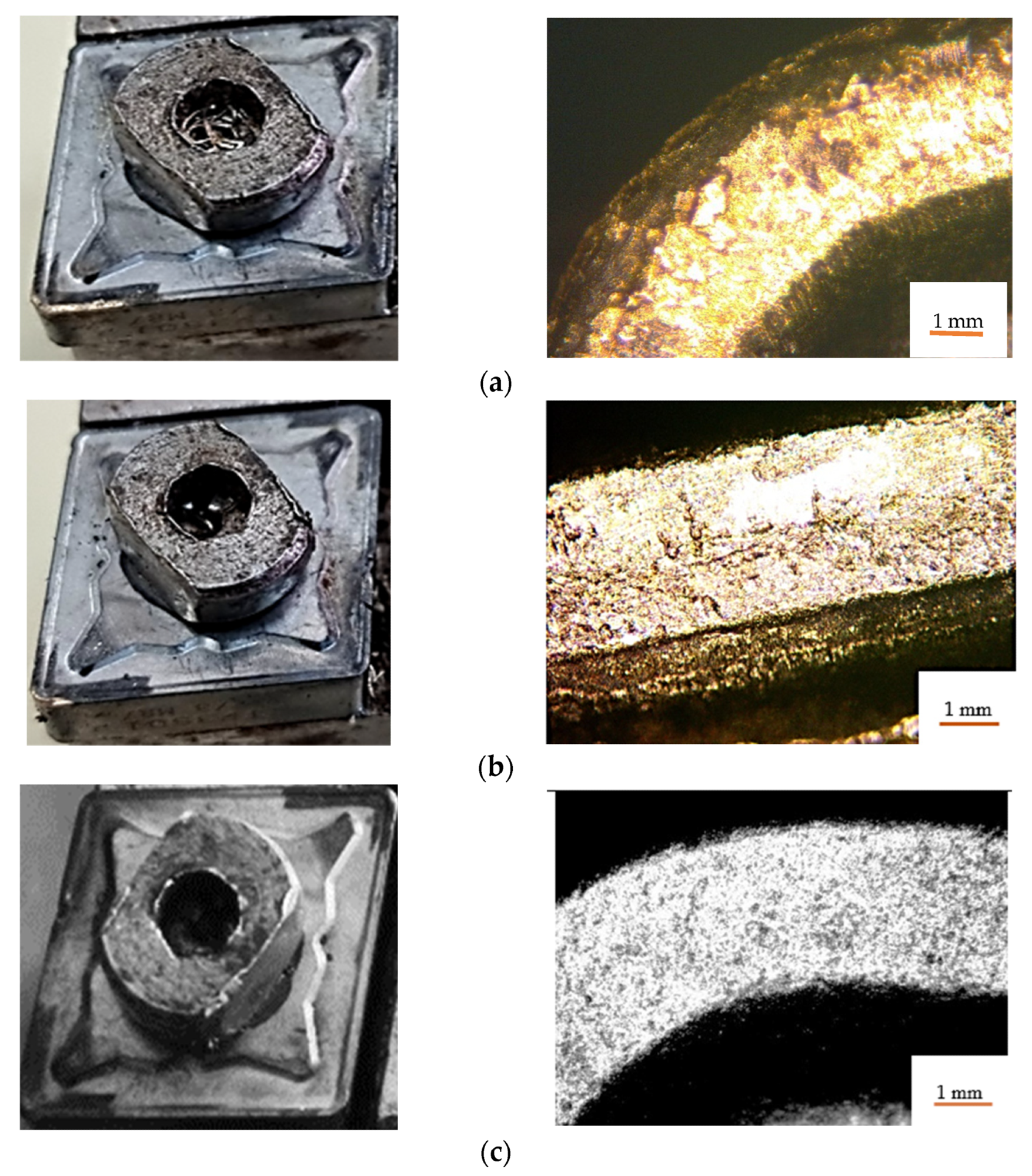

Deposits of processed material on the tool edge: (a)—for tool V01; (b)—for tool V02; (c)—for the tool V03. Image Credit: Dobrotă, D et al., Materials

Observations

According to the results, if a certain constructive version of the cutting tool was employed in the processing, the power needed for cutting could be reduced by roughly 30%, and the roughness of the processed surface could be reduced by approximately 90%–100%.

Furthermore, statistical analysis revealed that the cutting tool variant that delivered the largest reduction in roughness and cutting power must be used, particularly in roughing processes. The filtered profiles acquired with the tool V01 showed that roughness values varied dramatically over the length of the surface and reached values of ±10 µm. The highest roughness value was acquired when the tool V01 was used at a distance of 20 µm, and the lowest value was obtained when the tool V03 was used at a distance of 5 µm. The S5 sample, processed with tool V03, showed the greatest reduction of 30% in the value of the cutting power.

The use of the V03 tool, which permitted a 30% reduction in force size, not only reduced the temperature of the technical system's elements but also reduced the amount of high-frequency energy, which had a favorable influence on the roughness of the processed surfaces. The largest reduction in cutting pressures allowed for a reduction in cutting power and, indirectly, energy consumption. The surface roughness of the part was improved when the adherence of the processed material to the tool's cutting edge was lowered, which resulted in a link between surface roughness and energy usage.

Images with surface roughness obtained by cutting machining. Image Credit: Dobrotă, D et al., Materials

Conclusions

In conclusion, this study elucidated the development of a tool for machining materials like bronze-aluminum alloys that would save energy while maintaining a high quality of the processed surfaces. Furthermore, the measures conducted in the study allowed for the identification of the best parameters for obtaining the lowest energy consumption and lowest roughness of the processed surfaces. The cutting technique of the bronze-aluminum alloy was shown to be environmentally friendly.

The results illustrated how important it is to apply eco-design principles to the process of cutting aluminum alloys. The authors mentioned that the goal of future studies will be to look into the potential of using the findings for different types of instruments and processing techniques.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Dobrotă, D., Oleksik, M., Chicea, A.L., Ecodesign of the Aluminum Bronze Cutting Process. Materials 15(8) 2735 (2022). https://www.mdpi.com/1996-1944/15/8/2735.