In a lithium battery electrode, the level of charge at every scale is highly irregular. This is not good for the health of the battery. Thus, scientists from Rice University, in collaboration with the Department of Energy have looked in great detail at how several particles in an electrode tend to communicate with lithium while it is in use.

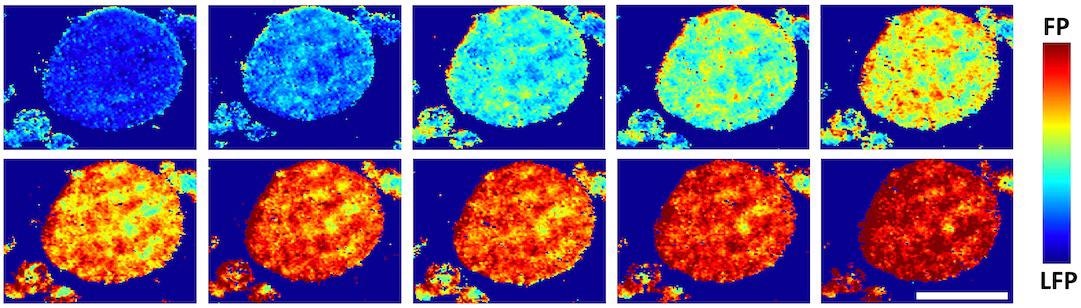

A phase map of an agglomerated particle in a common lithium iron phosphate (LFP) battery electrode shows the charge distribution as it goes from 4% to 86%. FP refers to iron phosphate. Rice University scientists found that the FP phase spreads nonuniformly on an aggregate surface upon charging, rather than the expected even spread of lithium over the surface. The scale bar is 10 microns. Courtesy of the Mesoscale Materials Science Group. Image Credit: Rice University.

Ming Tang, a materials scientist at the Rice laboratory, examined nano- and micro-scale interactions inside lithium iron phosphate cathodes via modeling and imaging provided by the transmission X-Ray microscopy abilities at Brookhaven National Laboratory and Argonne National Laboratory.

Their study in the American Chemical Society journal ACS Energy Letters assists theories developed by Tang and his collaborators several years ago that foretold how lithium travels in the lively surrounding within a normal commercial cathode.

Watching sealed cathodes charge and discharge at Brookhaven provided absolute proof.

Batteries have a lot of particle aggregates that soak up and give up lithium, and we wanted to know what happens on their surfaces, how uniform the reaction is. In general, we always want a more uniform reaction so we can charge the battery faster.

Ming Tang, Associate Professor, Materials Science and Nanoengineering, Rice University

At Brookhaven’s strong X-Ray synchrotron, the images taken allowed scientists to witness the regions inside the cathode that were better at absorption compared to others. The potential to face single or aggregated particles in 3D highlighted that, instead of reacting over their complete surfaces, lithium preferred specific regions over others.

This is very different from conventional wisdom. The most interesting observation is that these reaction regions are shaped like one-dimensional filaments lying across the surface of these aggregated particles. It was kind of weird, but it matched what we saw in our models.

Ming Tang, Associate Professor, Materials Science and Nanoengineering, Rice University

Tang stated that the lithium filaments appeared to look something like thick nanotubes and were measuring several hundred nanometers wide and several microns long.

Tang stated stress occurring between crystallites that are misaligned in the particle agglomerates prevents lithium from being evenly inserted into or extracted from the aggregate surface because that will produce too big an energy penalty. Rather, lithium has been forced to flow into or out of the aggregates at so-called “hot spots” that end up developing the filament shape.

What Does This Mean for Battery Performance?

This is a bad thing. Because the lithium can’t go into the cathode uniformly, it slows down the intercalation mechanics. What our study offers is some potential ways to help make lithium insertion or extraction more uniform on these aggregates or individual particles.

Ming Tang, Associate Professor, Materials Science and Nanoengineering, Rice University

Tang continued, “Introducing some porosity in the particle agglomerates might sacrifice some energy density, but at the same time would allow lithium to go in more uniformly. That could allow you to get more energy at a given charge/discharge rate.”

“Another thought is if we can somehow align the orientation of these small particles so their maximum expansion is perpendicular to each other, they’ll better accommodate lithium intercalation,” added Tang.

That would be a difficulty for battery manufacturers, admitted Tang.

Tang stated, “We don’t have enough experience in synthesis to know how to make that happen. What we’re providing is bait. Let’s see if somebody bites.”

The co-lead authors of the study are Rice graduate alumni Fan Wang and Kaiqi Yang. Co-authors are Mingyuan Ge, Jiajun Wang, Jun Wang, Xianghi Xiao and Wah-Keat Lee, all of Brookhaven National Laboratory, Upton, New York; and Linsen Li of Shanghai Jiao Tong University.

This study was financially supported by the Department of Energy, Basic Energy Sciences (DE-SC0019111), and the National Science Foundation (CMMI-1929949).

Journal Reference:

Wang, F., et al. (2022) Reaction Heterogeneity in LiFePO4 Agglomerates and the Role of Intercalation-Induced Stress. ACS Energy Letters. doi.org/10.1021/acsenergylett.2c00226.