A team of researchers from the North China Electric Power University and the State Grid Baoding Electric Power Supply Company in China have collaborated on a paper investigating the behavior of different silicon rubbers at extremely cold temperatures. The paper has been published in the journal Polymers.

Study: Research on the Influence of Extremely Cold Environment on the Performance of Silicone Rubber and Fluorinated Silicone Rubber. Image Credit: ZHMURCHAK/Shutterstock.com

Silicon Rubber and Fluorinated Silicon Rubber

Silicon rubbers have been widely applied in power insulation systems due to properties such as excellent electrical insulation and weather resistance. Fluorinated silicon rubber (fluorosilicone rubber) has been widely utilized in harsh environments for electrical insulation, especially in winter environments where extremely low temperatures are commonplace and can persist for extended periods of time.

In cold environments, traditional silicon rubber cannot meet the performance requirements of electrical insulation applications. Extremely low temperatures influence the performance of rubber insulation materials and can potentially cause catastrophic failure in seals and pipes. Studying the electrical and mechanical properties of rubber in cold environments is therefore necessary to select suitable insulating materials.

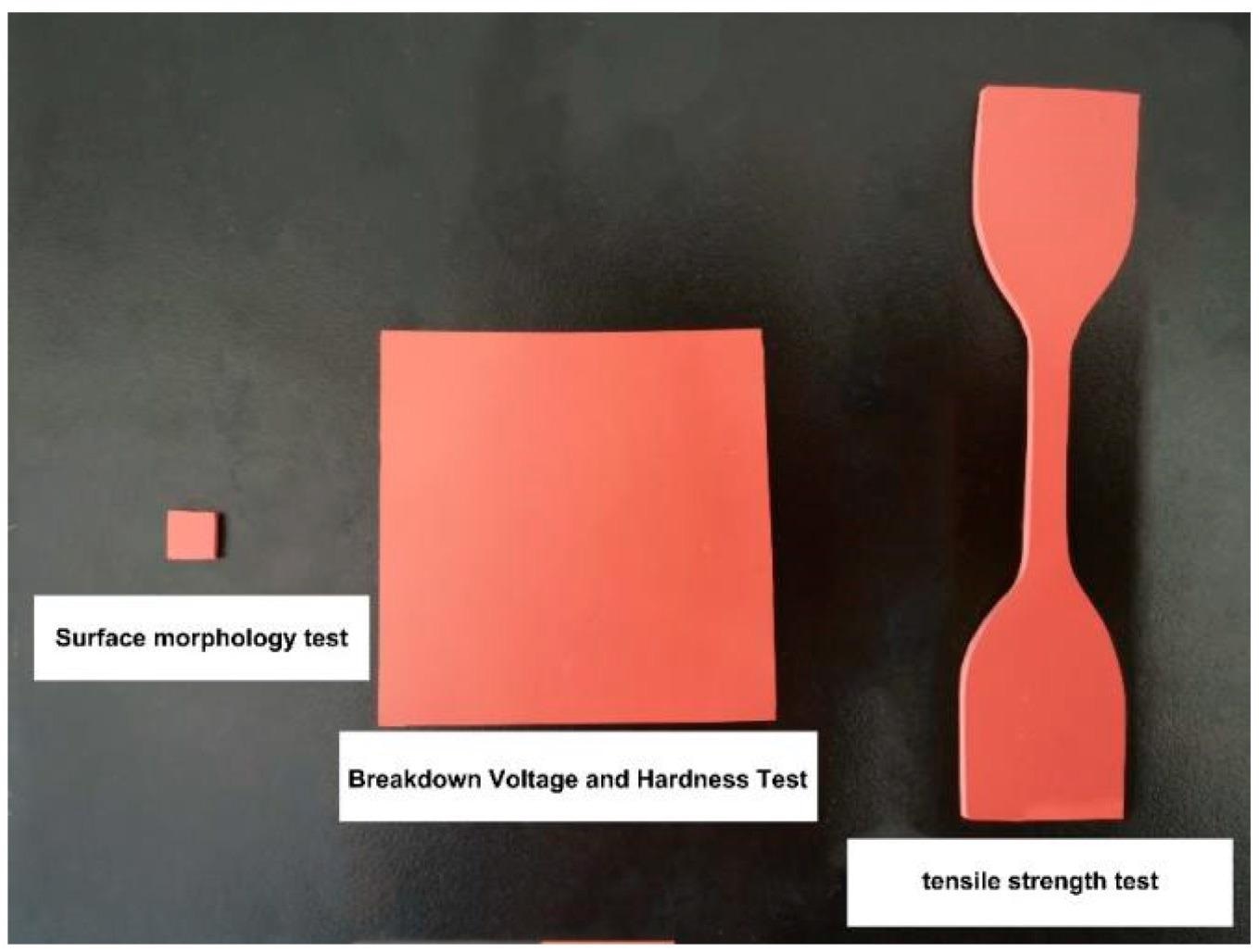

Test samples. Image Credit: Wang, S et al., Polymers

Previous Research

In recent decades, there have been several studies on the performance and properties of silicon rubber and fluorosilicone rubber. One paper has investigated the DC breakdown variation in these materials at different temperatures and with different aluminum hydroxide contents. Results of the study indicated that when the temperature is decreased, the breakdown voltage first increases and then stabilizes.

Other studies have indicated the effect of the feverish temperature environment in the power system itself on the breakdown characteristics of these materials. The morphology of the material’s electrical tree is dependent on elevated temperature and is related to molecular chain segment movements with increasing temperature.

Experiments with needle-plate electrode models at low temperatures have indicated that the electrical tree growth decreases at lower temperatures. Additionally, the type of electrical tree changes. Other research has reported perfect flexibility of silicon rubber/vinyl blends at low temperatures due to lower glass transition temperatures and a larger loss modulus and storage modulus.

It can be seen that the performance of silicon rubbers is influenced by lower temperatures. Presently, there are very few studies on the performance, mechanical properties, and breakdown characteristics of silicon rubbers and fluorosilicone rubbers at continuous extremely low temperatures.

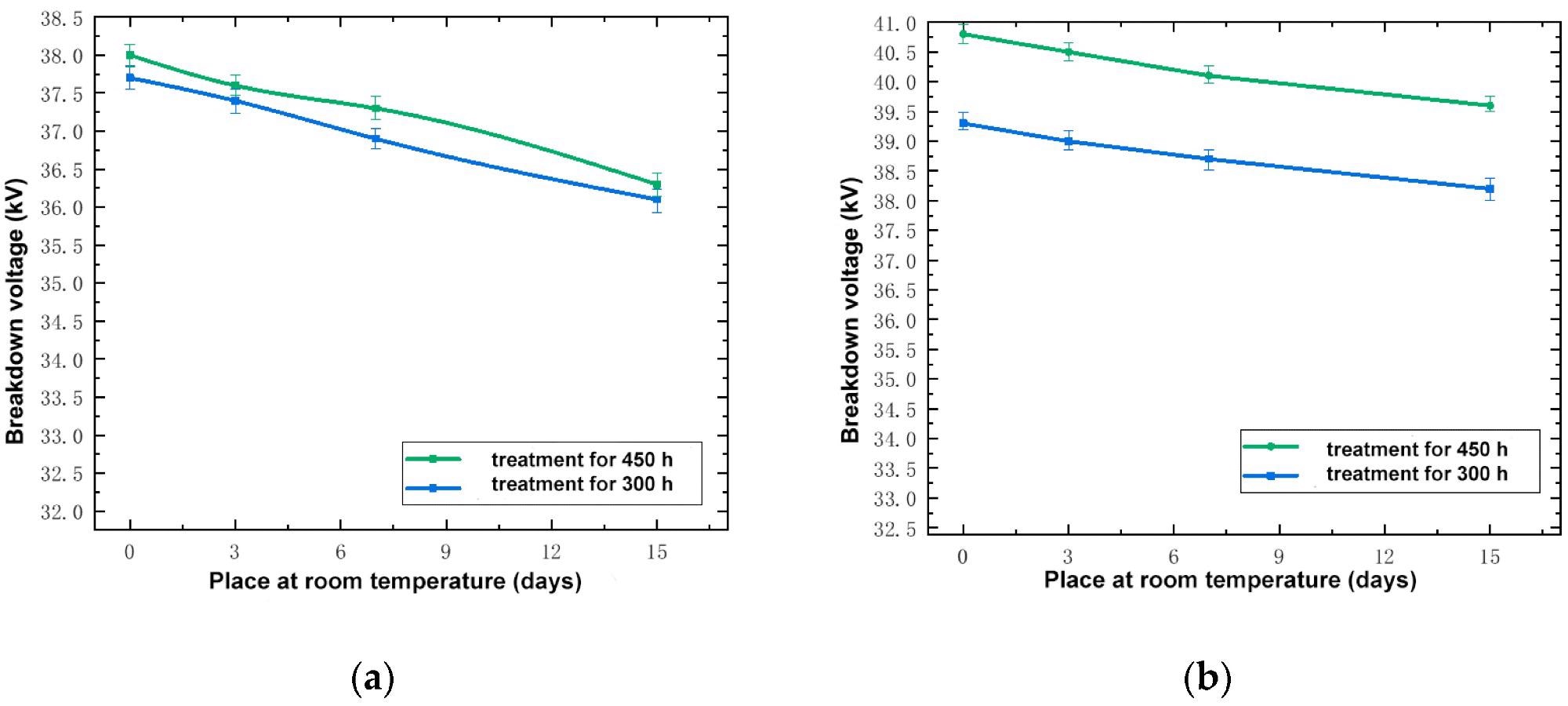

Relationship between breakdown voltage and days at room temperature. (a) Silicone rubber; (b) Fluorosilicone rubber. Image Credit: Wang, S et al., Polymers

The Paper

The paper has investigated the effects of continuously cold environments on both materials. The influence of these environments on elongation at break, tensile strength, maximum tensile force, breakdown voltage, surface morphology, and hardness were analyzed in-depth by the authors. Results of the research will help to inform the design of electrical insulation rubber for use in regions and times of the year which are subject to continuous sub-zero temperatures.

The authors have stated that the research will help guide the development of electrical insulation materials that can withstand damage from birds, short-circuit accidents, and wind deflection. This can result in overlap between phases and between phase and ground in environments which are subjected to extreme cold for extended periods.

Hebei Gui Gu Chemical Co., Ltd. supplied the material samples used in the research. GH-10 high-temperature vulcanized silicon rubber and FG-3 fluorosilicone rubber were analyzed by the authors. Preparation of test sample was conducted according to Chinese national standard DL/t376.

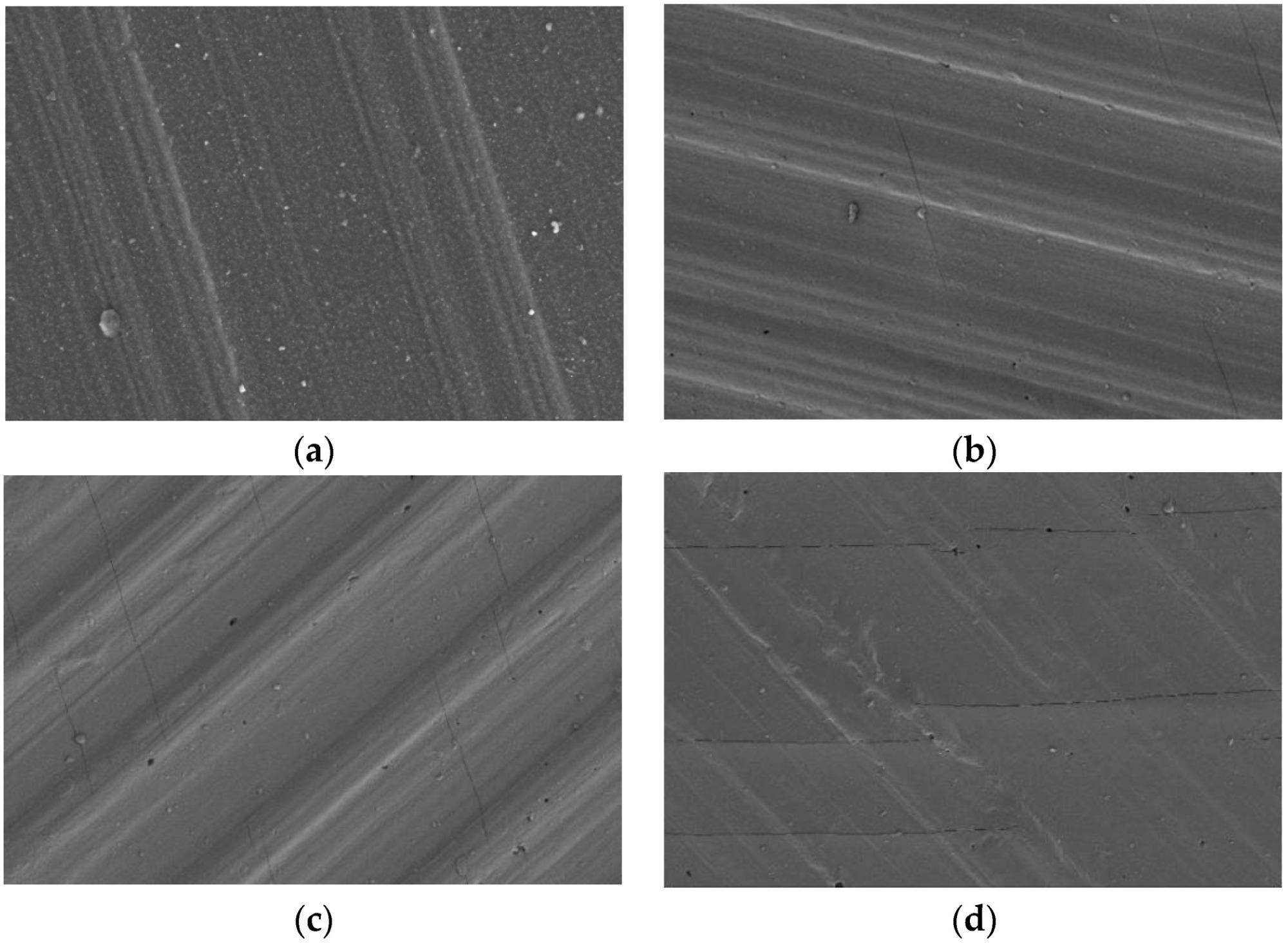

Surface morphology changes with low temperature freezing time. (a) Freezing 0 h, (b) Freezing 300 h, (c) Freezing 750 h, (d) Freezing 1050 h. Image Credit: Wang, S et al., Polymers

Samples with different dimensions (6x6x2 mm cuboid, 60x60x20 mm cuboid, and dumbbell) were used for each test. Smaller cuboids were used for surface morphology tests, larger cuboids for hardness and breakdown voltage tests, and dumbbells for tensile properties tests. Samples were evaluated in a low-temperature test chamber at a constant -50 oC.

Samples were tested over different periods of time (0, 150, 300, 600, 750, 900, 1050 h) and then removed. They were then placed in a 25 oC environment for 2 hours, and tests were performed on the relevant parameters. Five test data values were employed to average the mechanical parameter and breakdown voltage values to reduce error.

Results indicated that between 0 and 300 h, the breakdown voltage of both materials increased significantly and then increased more slowly after this freezing time. Silicon rubber’s breakdown voltage was essentially unchanged, whilst fluorosilicone rubber displayed a marginal increase. Out of both materials, the breakdown voltage of fluorosilicone rubber was higher, regardless of the time period. Fluorosilicone rubber performs better as an electrical insulator under extreme cold conditions.

The fluorosilicone rubber samples also possessed higher tensile properties, elongation performance, lower hardness, and enhanced elasticity than the silicon rubber samples evaluated in the research. Overall, the results indicate that fluorosilicone rubber performs better in conditions of extreme cold for longer periods than silicon rubber and is suitable for electrical insulation purposes.

Further Reading

Wang, S et al. (2022) Research on the Influence of Extremely Cold Environment on the Performance of Silicone Rubber and Fluorinated Silicone Rubber Polymers 14(9) 1898 [online] mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/9/1898/htm

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.