By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 16 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 16 2022In an article recently published in the open-access journal Sustainability, researchers discussed the drying of food waste and its further utility as animal feed.

Study: Drying of Food Waste for Potential Use as Animal Feed. Image Credit: OhLanlaa/Shutterstock.com

Background

Food waste (FW) generation and disposal are one of the world's most serious environmental issues. The demand for natural food sources grows as the world's population increases. To prevent squandering these important items and to promote a healthy environment while lowering greenhouse gas emissions, it is critical to reuse and recycle FW. The drying of FW is a good way to store it and extend its shelf life.

Radiative–convective drying appears to be the most effective method for drying food waste, but due to the high energy requirements, convective dryers must be connected to a low-cost energy source in order for the drying process to be environmentally and economically efficient and sustainable.

One of the most critical factors affecting harmful microbe survivability in FW during transit and processing is ambient air relative humidity.

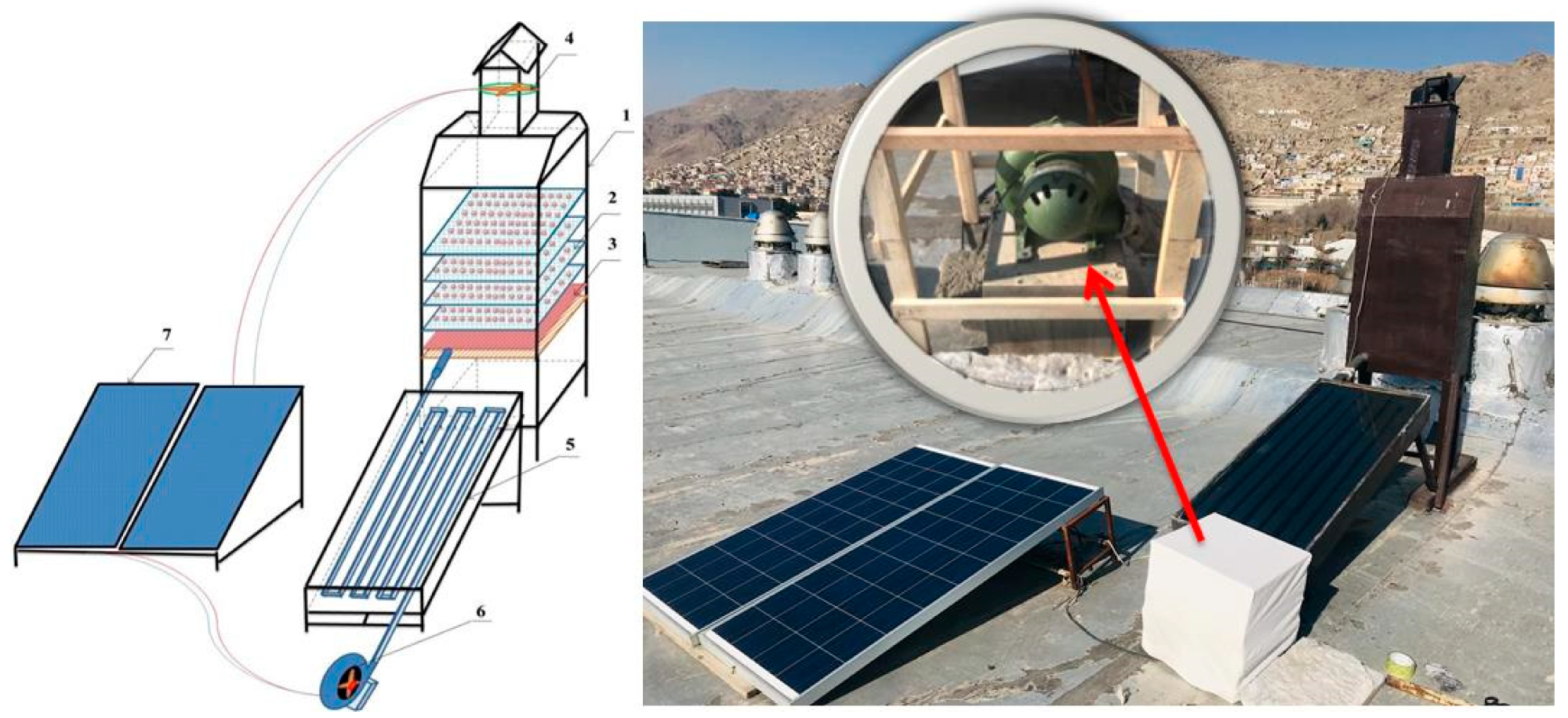

Schematic description of solar dryer: 1—drying chamber, 2—drying trays, 3—air distributor, 4—DC exhaust fan, 5—collector, 6—DC centrifugal blower, and 7—PV solar panel. Image Credit: Noori, A. W et al., Sustainability

About the Study

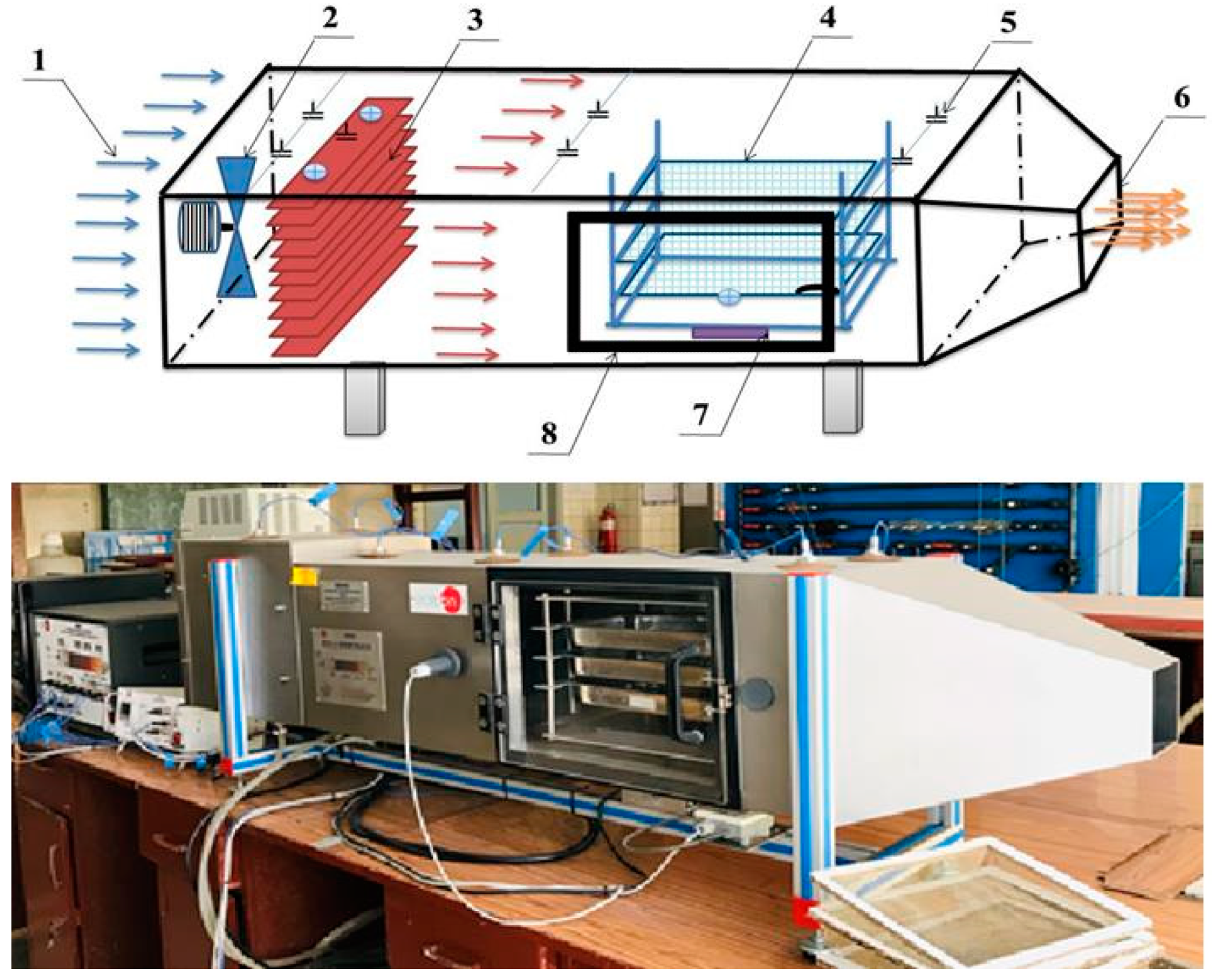

In this study, the authors investigated the prospect of drying and recycling food waste as a component of animal feed utilizing indirect solar drying. As a control, a convective laboratory dryer was employed. The effective diffusion coefficient of water in FW was calculated using a simplified version of Fick's second law.

The team determined the potential of food waste from Kabul wedding halls to be processed into animal feed in a sustainable manner using solar energy in a convective solar drying system. The effect of changing weather conditions on process kinetics and product water activity was also demonstrated. Further, the nutritional value and microbiological safety of the dried food waste were evaluated.

The researchers used an energy-independent active indirect solar drying (AISD) system for FW drying. Air velocity inside the aluminum pipe was used to estimate the airflow rate. J-type thermocouples were used to measure temperatures at the collector inlet and outlet, as well as the chamber inlet and outlet. Psychrometric measurements of dry- and wet-bulb temperatures were used to determine air relative humidity.

Convective batch laboratory tray dryer scheme: 1—air inlet, 2—centrifugal blower, 3—heater, 4—drying trays, 5—sensors, 6—air outlet, 7—balance load cell force, and 8—drying chamber. Image Credit: Noori, A. W et al., Sustainability

Observations

The FW produced in Kabul's 121 wedding venues, which amounted to over 7000 tonnes each year, had significant potential for drying and reuse as an animal feed component. The temperature, relative humidity, and intensity of sunlight had a considerable impact on drying kinetics. One sunny day with a temperature of 30–36 °C, relative humidity of 15–30%, and solar radiation intensity of 500–1100 w m-2 was able to dry a 5 mm thick layer of ground FW and lowered its water activity below 0.3 and the corresponding moisture content below 8%.

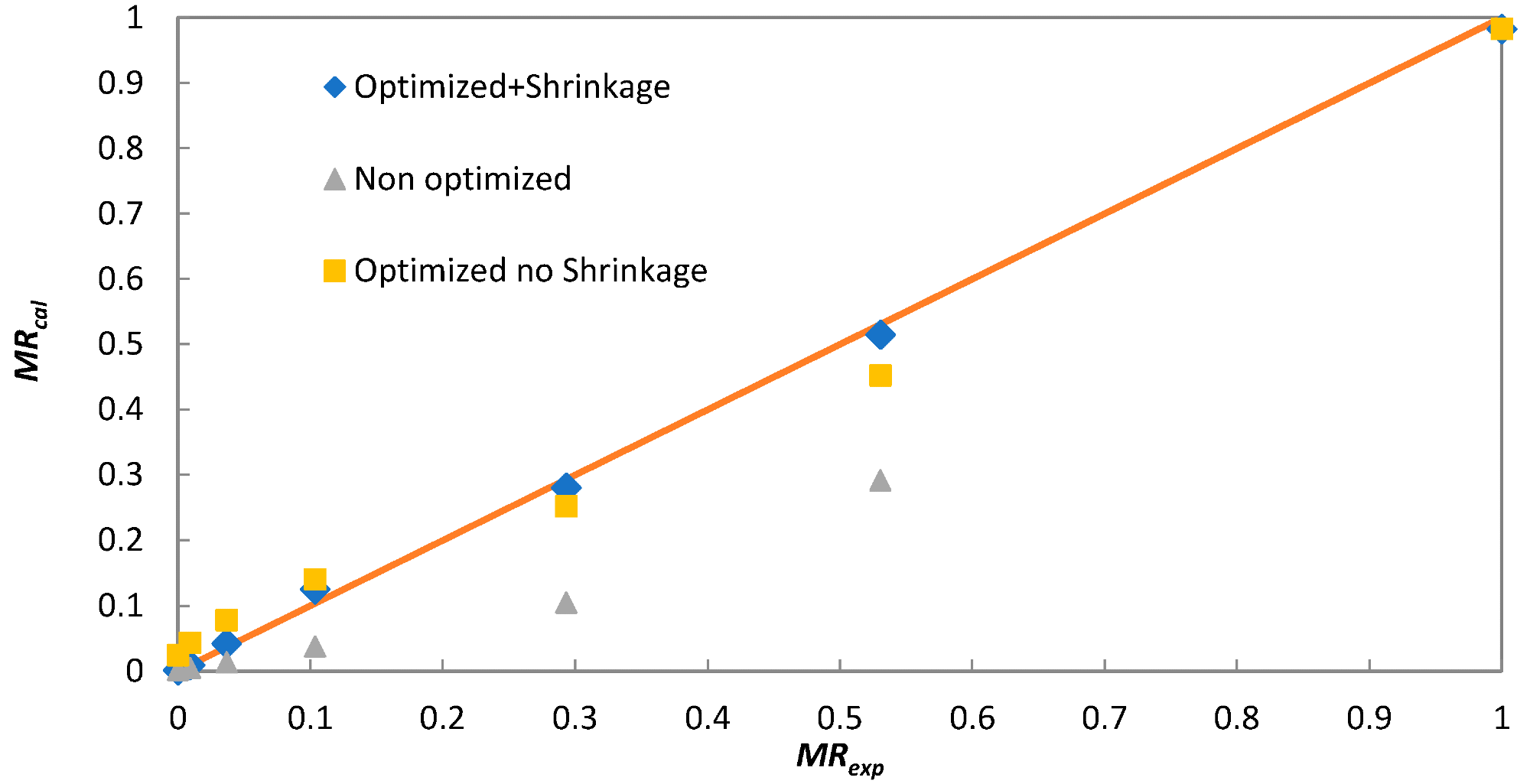

The optimization of the basic one-member solution resulted in a considerably better estimation of the effective diffusion coefficient (Deff) with a better fit of experimental data. Protein, carbs, fat, and ash were all present in the analyzed FW; however, the protein amount in the dried FW was lower than in the usual diet. Protein materials such as soybean meal could be used to correct this shortage.

Comparison of experimental (MRexp) and calculated (MRcal) moisture ratios for solar dryer experiment (Day 3). Image Credit: Noori, A. W et al., Sustainability

Weather fluctuations had an impact on drying kinetics and the effective diffusion coefficient, as well as the nutritional composition of dried feed and the microbiological characterization of the dried product. A more complicated solution of Fick's second law paired with an optimization process resulted in a much better fitting of experimental and model drying curves.

The nutrients in the analyzed food waste were a decent mix of fat, protein, and carbs; however, the protein amount in the dried food waste was found to be lower than in the regular feed. The overall microbial counts of dried samples were reduced by more than half after autoclaving new samples.

The total microbial count of non-autoclaved dried materials was 4.4 x 105 CFU g-1 in laboratory batch studies and 2.1 x 107 CFU g-1 in solar drying trials, according to microbiological analyses. In non-autoclaved dried samples, significant counts of aerobic scores, S. aureus, yeast, coliforms, E. coli, and molds were identified. In solar-dried samples, S. aureus and E. coli were not found. High-quality air conditioning was necessary to reduce product recontamination.

Conclusions

In conclusion, this study elucidated that solar drying, as a sustainable method, has a lot of potential for converting the FW to animal feed in dry climates. However, the authors emphasized that further study is needed to fully commercialize the use of dried FW as animal feed by resolving all logistical, technological, and societal aspects of the problem. They also mentioned that the impact of adding certain substances on nutritional product content, the impact of air-filtering on microbiological counts, and feeding animals with the corresponding product are all topics that will be investigated in the future.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Noori, A. W., Royen, M. J., Medved’ová, A., et al. Drying of Food Waste for Potential Use as Animal Feed. Sustainability 14(10) 5849 (2022). https://www.mdpi.com/2071-1050/14/10/5849