Due to their great performance and cheap production cost, perovskite solar cells have great potential as a future energy technology. However, due to the difficulties in scaling up from small-scale laboratory devices to large-scale modules or panels required for commercial usage, researchers are finding it difficult to bring this potential photovoltaic technology into commercial use.

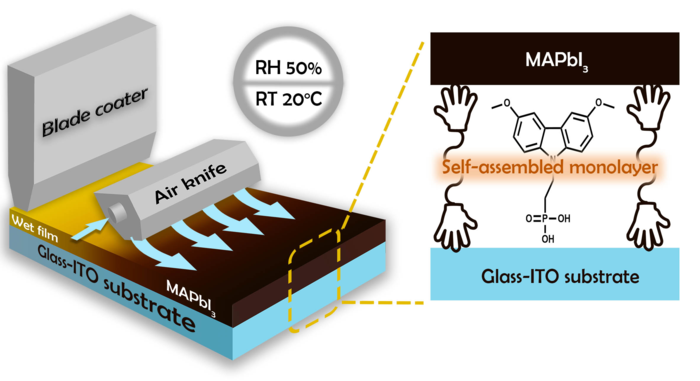

The application of self-assembled monolayer enables a dense interfacial contact between the substrate and the blade-coated perovskite layer, allowing enhanced photovoltaic performance and device stability. Image Credit: Nano Research Energy.

The application of self-assembled monolayer enables a dense interfacial contact between the substrate and the blade-coated perovskite layer, allowing enhanced photovoltaic performance and device stability. Image Credit: Nano Research Energy.

A research team has shown that utilizing a blade-coating approach, a self-assembled monolayer could be used to produce a large-area perovskite film, promoting the upscaling of perovskite photovoltaic technology. Researchers hope that their innovative approach will allow perovskite solar cell technology to be commercialized.

On May 12th, 2022, the team published their findings in Nano Research Energy.

Photovoltaic solar cells transform light energy into electricity using semiconductors. Silicon has been the major semiconductor material used in solar cells since the 1950s. Developing massive silicon crystals, as required by traditional solar panels, however, necessitates costly and time-consuming manufacturing procedures. Perovskites have been used by scientists to create semiconductors with characteristics similar to silicon.

Perovskites, with their unique crystal structure, are named after a mineral with a similar structure. Perovskites can be made at a lower cost and with less energy than silicon. Perovskite solar cells are also lightweight and adaptable, allowing them to be employed in areas like windows and curved rooftops. The world record efficiency of perovskite solar cells is 25.7%, which compares the efficiency to that of silicon solar cells.

Perovskite solar cells are made by depositing layers of material on an underlying layer called the substrate. The researchers discovered that the surface features of the substrate are crucial for large-area coating and perovskite development when developing the high-speed blade-coating approach for perovskite thin-film deposition. The present method leaves voids at the buried interface of the perovskite layer, which has a negative impact on device performance.

To solve this problem, we have screened various hole-transporting materials and found that self-assembled monolayers are a class of promising materials for the upscaling of perovskite devices.

Alex Jen, Professor, City University, Hong Kong

Organic molecules are arranged in an orderly array in self-assembled monolayers. They have a functional headgroup that can connect to the substrate and an anchoring group that can passivate faults for the perovskite on top. These self-assembled monolayer molecules act as linkers, tightening the connection between the substrate and perovskite layers and eliminating interfacial voids.

Furthermore, since the self-assembled monolayer is a monolayer, charge carriers can be extracted from perovskite to substrate electrode efficiently through charge tunneling, resulting in enhanced device performance.

Alex Jen, Professor, City University, Hong Kong

Due to the little amount of material required, these functional self-assembled monolayers that may be solution-processed are particularly cost-effective. Self-assembled monolayers are effective when it comes to controlling perovskite development and passivating any potential defects.

This novel class of materials is very promising for facilitating the upscaling of perovskite photovoltaic technology.

Alex Jen, Professor, City University, Hong Kong

The researchers propose to use various self-assembled monolayer molecules tailored for upscaling perovskite solar technology in future experiments. The team wants to perform composition engineering of perovskite precursors for upscaling coating techniques in addition to further investigation of self-assembled monolayer molecule design and synthesis. It is crucial to understand how perovskite and self-assembled monolayers interact.

The coating of perovskites must be homogeneous and defect-free in order to create highly efficient and reliable solar modules. “We believe our research will help reduce the lab-to-fab gap to facilitate the commercialization of perovskite photovoltaic technology,” added Jen.

Jie Zeng, Leyu Bi, Yuanhang Cheng, and Alex K.-Y. Jen of the City University of Hong Kong; and Baomin Xu of the Southern University of Science and Technology in Shenzhen, China, make up the research team.

This study is supported by an APRC grant from the City University of Hong Kong and a GRF grant from the Hong Kong Research Grants Council.

Journal Reference:

Zeng, J., et al. (2022) Self-assembled monolayer enabling improved buried interfaces in blade-coated perovskite solar cells for high efficiency and stability. Nano Research Energy. doi.org/10.26599/NRE.2022.9120004.