A team of researchers recently published a paper in the journal Carbon that demonstrated the feasibility of using thermally reduced large-sheet graphene oxide (LGO) for high-efficiency microwave absorption (MA).

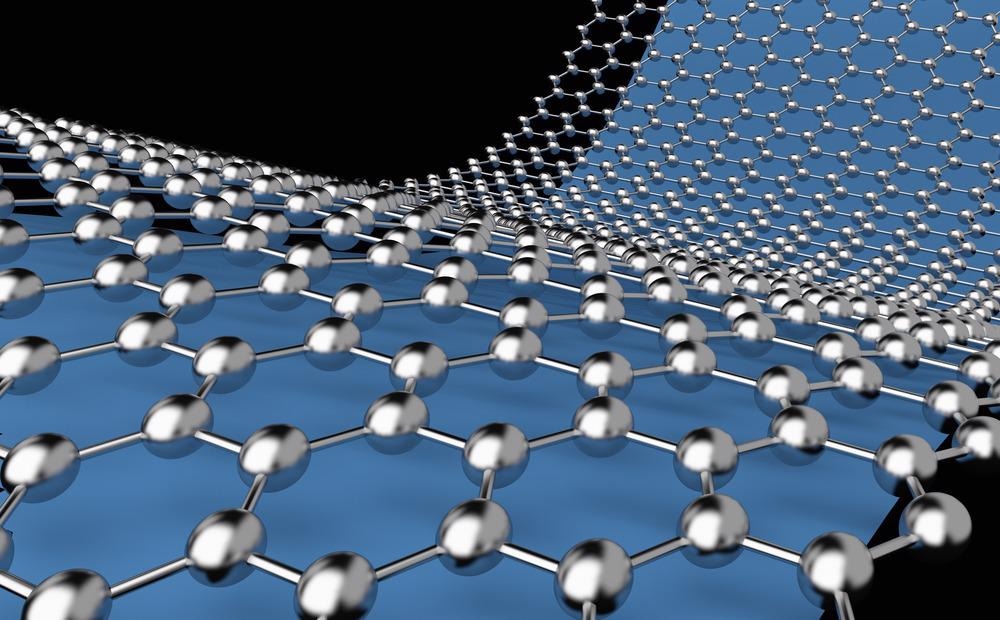

Study: Light-weight, low-loading and large-sheet reduced graphene oxide for high-efficiency microwave absorber. Image Credit: Ambelrip/Shutterstock.com

Background

The exponential growth of electronics and communication technology and the gradual introduction of 5G have forced people to live in a complex electromagnetic interference environment, severely affecting human health and information security.

Microwave absorbing materials can be used to address this problem. Specifically, lightweight, low-loading materials with high efficiency can effectively solve this issue as electromagnetic devices have become lightweight and miniaturized.

Currently, magnetic materials are used extensively in microwave absorbing materials. However, these materials are ineffective for efficient MA, which necessitated the identification of new microwave absorbing materials.

Carbon materials can be suitable for MA. These materials are utilized in absorbing materials as they are lightweight and possess customizable dielectric properties and high specific surface area. Graphene is used extensively among carbon materials as it is the thinnest and lightest material.

Graphene foam (GF) with a material density of 1.6 mg/cm3 and a reflection loss (RL) of -34 dB was prepared by controlling the reduction temperature and solubility of GO. The MA performance of the foam was tuned through simple physical compression. GF with a qualified bandwidth of 60.5 GHz was obtained under 90% compressive strain.

However, the high conductivity of graphene deteriorates the impedance matching conditions and creates an imbalance of electromagnetic parameters, which hinders any further rise in the MA capacity.

GO was widely investigated for MA due to its exceptional dielectric processability. Abundant surface defects are primarily responsible for the MA ability of GO. In the graphene derivative, oxidized functional groups and vacancies can attenuate the microwave by polarization, while the change in the activated carrier mobility leads to microwave conduction loss.

The synergistic effect of these factors provides an excellent absorption capacity to GO. The thermal reduction of GO in a high-temperature and inert atmosphere can deoxidize the surface functional groups and reduce the GO functional group content.

In reduced graphene oxide (rGO), the dielectric and conductive permeation thresholds are 0.31 and 0.52 vol%, respectively. Thus, a small filler addition is required to obtain exceptional conductive properties.

However, compounding rGO with other conductive polymers or magnetic materials can lead to high loading and increase the complexity of the preparation process. Single rGO is also ineffective for MA absorption due to poor absorbability.

The Study

In this study, researchers synthesized rGO with different reduction degrees by reducing LGO using the controlled thermal reduction method, characterized the synthesized samples, and investigated their MA properties. Specifically, the influence of different reduction temperatures and loadings on the absorption capacity was examined.

The modified Hummers method was used to synthesize LGO from expanded graphite (EG). Sodium nitrate and EG were added to sulfuric acid and stirred in an ice bath. Potassium permanganate was then gradually added to the mixture in a continuous agitation and the mixture temperature was maintained below 5 ℃.

The as-obtained mixture was kept for two h at 35 ℃, and then deionized water was added slowly to the mixture at a reaction temperature below 60 ℃. Subsequently, an appropriate amount of hydrogen peroxide was added to the mixture to eliminate the unreacted potassium permanganate to obtain the golden yellow solution.

The remaining sulfuric acid was eliminated through repeated centrifugation until the formation of a neutral upper suspension. Eventually, the GO suspension was obtained.

A lyophilizer was used to freeze-dry the obtained GO solution into GO solids, which were then separated into four GO solids. These four GO solids were reduced at 1000, 800, 600, and 400 ℃ for two h at a 5 ℃/min ramp rate in argon to obtain rGO MA materials with different reduction degrees, which were designated as RT1000, RT800, RT600, and RT400 based on their reduction temperatures. The untreated GO was designated as GO.

Powder X-ray diffraction (XRD), Raman spectroscopy, X-ray photoelectron spectroscopy (XPS), scanning electron microscopy (SEM), transmission electron microscopy (TEM), and atomic force microscopy (AFM) were used for characterization of the synthesized samples. An Agilent-E5230A/B/C vector network analyzer (VNA) was utilized to determine the relative permittivity and permeability during MA measurements.

Observations

Researchers successfully synthesized rGO MA materials with multiple reduction degrees by reducing LGO sheets. Subsequently, they mixed the rGO MA materials using a simple mixing process to obtain mixed rGO MA materials with exceptional impedance matching and absorbing properties.

GO sheets with more than 25 μm lateral dimensions were designated as LGO in this study. LGO demonstrated a better absorbability and impedance matching at lower loadings owing to their easier conductive network formation and richer polarization centers on the surface. Moreover, the carbon-oxygen (C-O) bonds of LGO sheets improved their dielectric properties.

Thermal reduction of LGO led to the elimination of oxygen-containing functional groups and the presence of more nanopores on the rGO surface. This structural change facilitated the absorption and reflection of microwaves in graphene. The rGO sheet size and reduction degree significantly influenced the rGO MA performance.

The RL reached a maximum value of -53.0 dB and its effective absorption bandwidth (EAB) was 3.98 GHz in 1.60 mm-thick RT800 MA material when the loading and reduction temperature was 1.5 wt% and 800 ℃, respectively. The rGO impedance matching was improved due to the mixing of rGO with different degrees of reduction.

The RL attained the value of -59.1 dB and its EAB was 3.54 GHz in the 4.04 mm-thick mixed RT400/RT600 rGO MA material with only 1.0 wt% RT600 and 0.5 wt% RT400 loading. The impedance matching was close to one, indicating a good matching performance. The RL value of the mixed RT400/RT600 was 1.59 and 2.13 times higher than the individual RT600 and RT400 materials, respectively. The optimum EAB was 6.90 GHz, covering the entire Ku band when the loading was 1.5 wt%.

Taken together, the findings of this study demonstrated the effectiveness of large-sheet, low-loading, and lightweight rGO as an efficient MA material.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Fu, Q., Liu, T., Luo, N. et al. Light-weight, low-loading and large-sheet reduced graphene oxide for high-efficiency microwave absorber. Carbon 2022. https://doi.org/10.1016/j.carbon.2022.05.062