When a short circuit happens, the molten markings’ morphology adapts to the surrounding conditions. It's crucial to look at microstructural alterations to comprehend copper's characteristics and determine what started a fire. The latest study published in the journal Materials thoroughly analyzes the grain-size distribution and boundary characteristics of primary-arc beads (PABs) and secondary-arc beads (SABs).

Study: Potential Method to Distinguish Copper Molten Marks Using Boundary and Grain Characteristics. Image Credit: Andrei Stepanov/Shutterstock.com

Short Circuit – A Leading Cause of House Fires

One-third of the primary culprits of electrical accidents in housing areas are short-circuited arcs in electric cables brought on by worn-out and inadequate sheathing. Although it is believed that far more electrical accidents associated with electrical cables may have happened, 51 percent of fires brought on by technical issues in residential units were from unidentified electrical fault and malfunctioning.

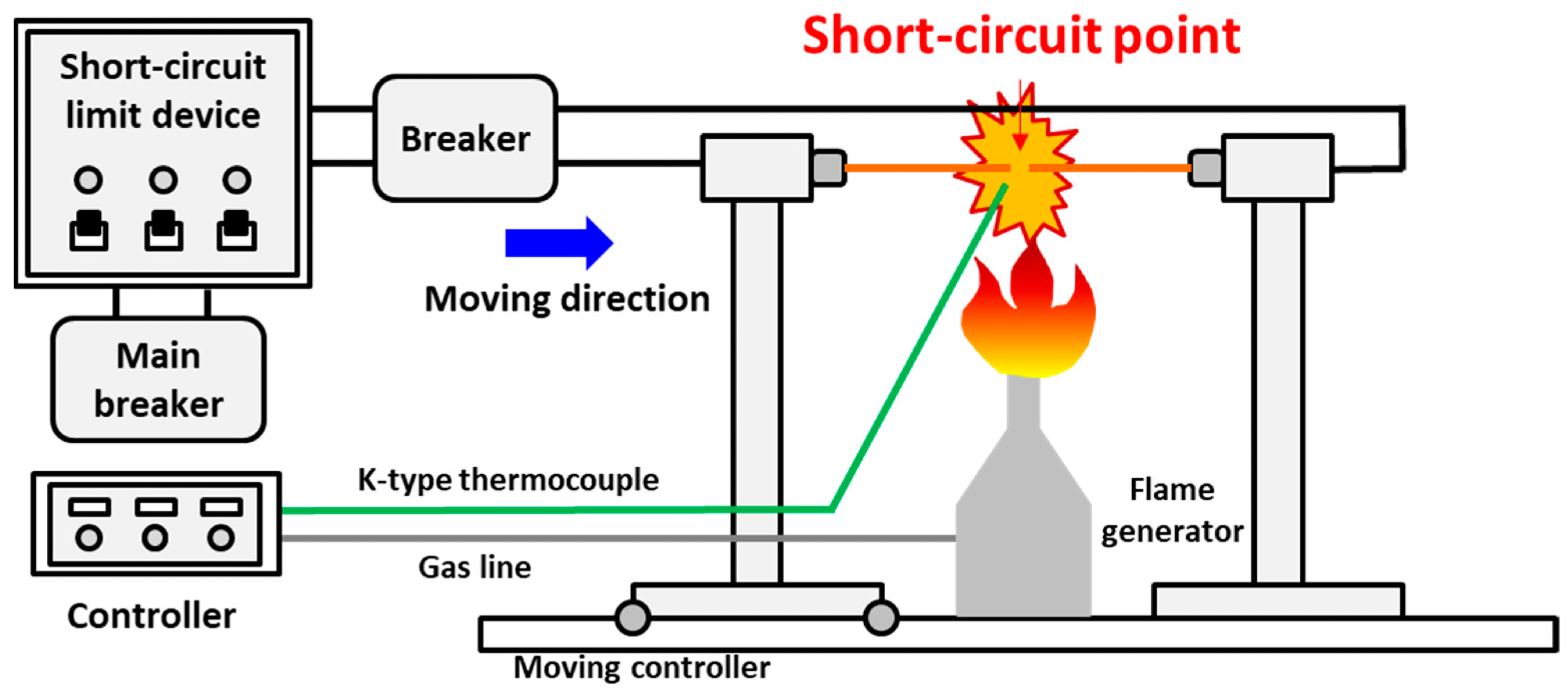

Schematic illustration of the short-circuit generator. Image Credit: Park, J. et. al., Materials

Why Does it Become Difficult to Identify the Cause of Fire?

The fact that it is unknown whether the molten markings found on the cables are the origin or the outcome of the fire is one of the factors contributing to the increase in the number of unexplained fire cases. Therefore, fires with unknown origins can be decreased if the reason for the production of molten markings is fully understood.

A Brief Introduction to Molten Marks

A bead hardening after the cable melts is referred to as a molten mark, whether it is brought on by electrical or thermal activity. Generally speaking, there are three sorts of molten imprints on wires that are frequently discovered at fire scenes.

Primary-arc beads (PABs) are sparks that result from faulty conditions after being damaged by deteriorated insulation or any external factor. Secondary-arc beads (SABs) are melted marks left behind by short circuit arcs that occur when a cable's coating melts as a result of an environmental spark. Globules are the third type, which are the molten markings that solidify when the copper cable dissolves in a non-energized phase wing to external flame.

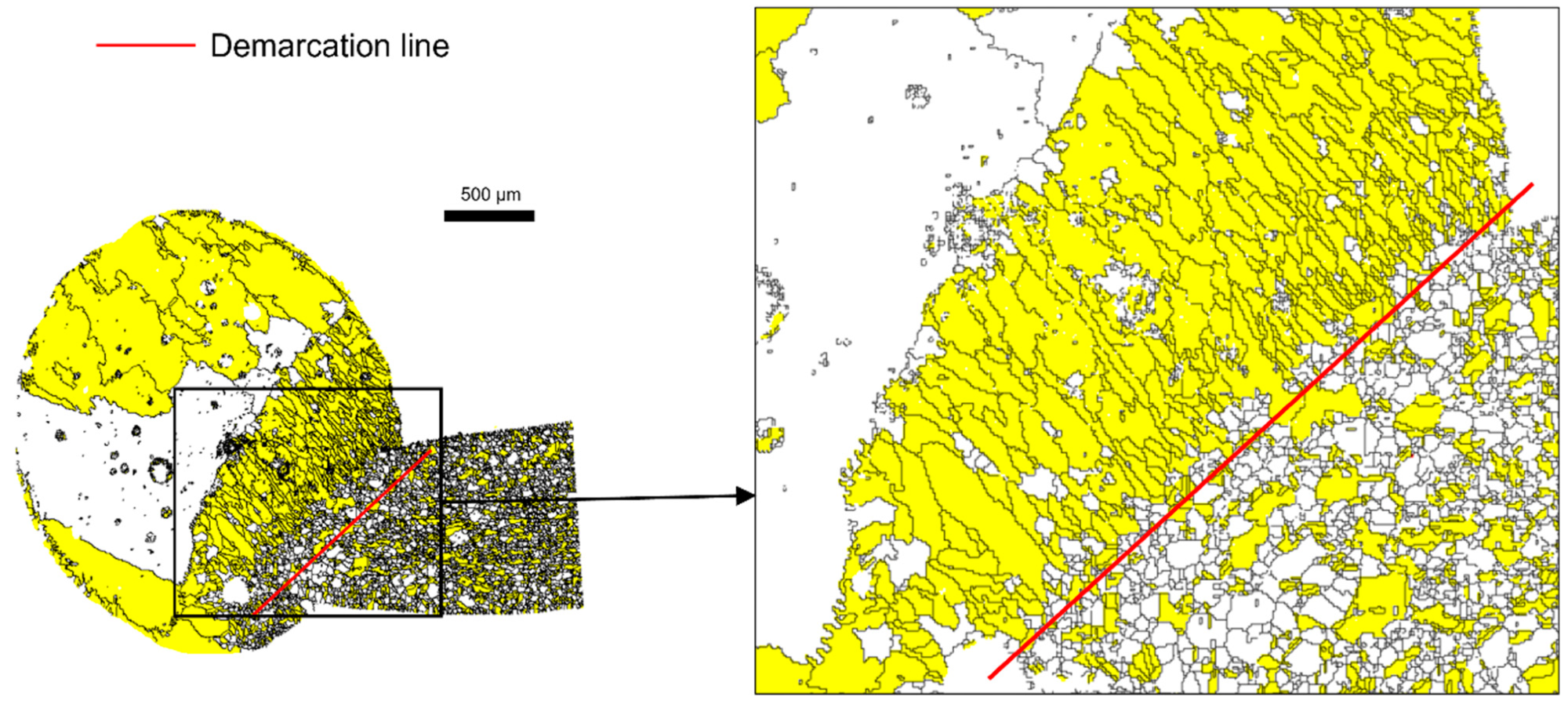

Set demarcation line of the molten mark: the region with grain aspect ratio (GAR) < 0.45 (yellow color) and demarcation line (red line). Image Credit: Park, J. et. al., Materials

Importance of Molten Marks in Origin Identification

Identifying the exact type of liquefied marks is crucial to pinpointing the origin and locality of fires because fire inspections involve studying the occurrence, structure, and appearance of molten markings. With the unaided eye, globules and short-circuit molten markings (PABs, SABs) can be distinguished. However, it can be difficult to distinguish between PABs and SABs precisely.

The amount or magnitude of porous marks in the molten marks, the presence of amorphous or graphitic carbon in the molten marks, and the dispersion of O2 and carbon concentrations in the molten marks among others have all been recommended as standards to differentiate PABs from SABs as a result. However, owing to a shortage of quantifying methods and validation, several recommended criteria for differentiating between PABs and SABs have been challenging to implement.

Criteria for Demarcation Line

A boundary separating the melted and un-melted components is created as the molten marking left by the short-circuit energy on the copper cable quickly solidifies. As a clear criterion to determine the demarcation line has not been standardized, a novel one employing the special features of the columnar structure in the molten component was proposed in the most recent study.

The columnar composition was determined by the grain aspect ratio (GAR), which was employed as a criterion. It is equal to the minor axis span divided by the dimension of the main axis. The more circular and elliptical the object, respectively, the more GAR is closer to 1 and 0 respectively.

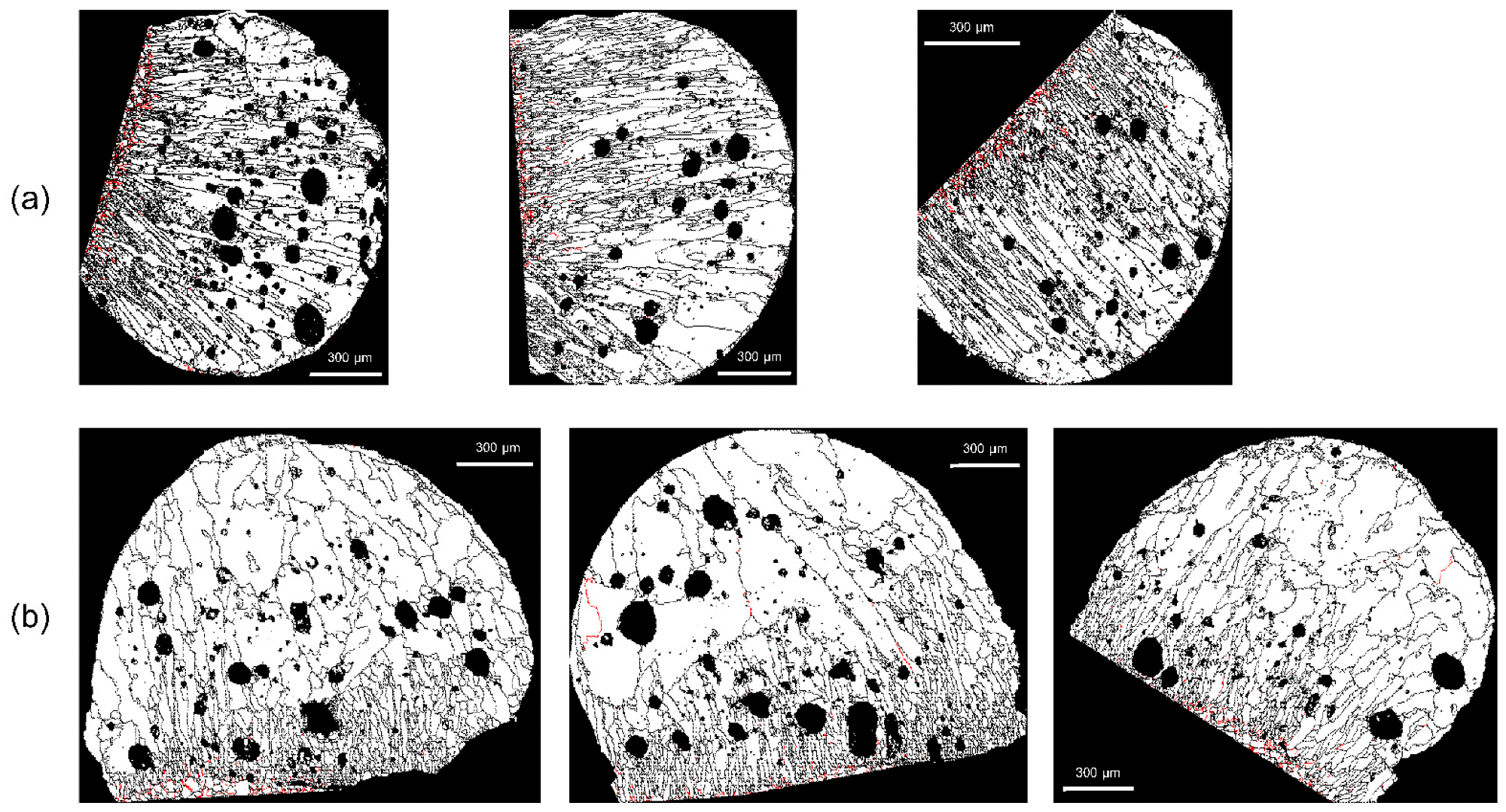

Distribution of Σ3 boundaries (red line) in the molten marks: (a) PAB-25 and (b) PAB-600. Image Credit: Park, J. et. al., Materials

Research Findings

Modifications in the columnar grains (yellow region) were seen as the GAR was adjusted from 0 to a particular value. The molten portions were where the columnar grains were mostly produced.

The proposed distinguishing criterion was not satisfied by the two melted markings of PAB-600 and SAB-900. Since the melted marks were continually subjected to 600 °C even after the short circuit, the formation of coarse grains and the alignment of the grains led to the data dispersion of PAB-600 close to the discriminant line.

The percentage of Σ3 borders was lowest in PAB-25 at 1.796 percent and highest in SAB-900 at 9.801 percent. In PAB-600, there were 2.197 percent Σ3 borders, which is 0.401 percent more than in PAB-25. Three limits may have formed because recrystallization took place during heating at 600 °C.

Small grains in SABs were comparable to those in PABs near the demarcation line, but inside the melted region of SABs, comparatively big granules and comparatively equiaxed morphology were observed. As a result, it is anticipated that contrasting the size (area) of the biggest granules from each melted marking will enable the presentation of a parameter for differentiating PABs from SABs.

Even though the research has created useful fire analysis criteria, it would be beneficial to investigate in the future the structural traits of molten markings in encased wires using compartment fire testing.

Further Reading

Park, J. et. al. 2022. Potential Method to Distinguish Copper Molten Marks Using Boundary and Grain Characteristics. Materials. 15. 4534. Available at: https://www.mdpi.com/1996-1944/15/13/4534

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.