Waterborne dyes are typically made from emulsified resins, which are made up of trillions of tiny resin particulates. The latest study published in the journal Materials looked at how different pigments affected the performance of waterborne emulsion paint.

Study: Effects of Selected Pigments on the Properties of Silicone Resin-Based Paints. Image Credit: RossHelen/Shutterstock.com

Waterborne Emulsion Paints

Waterborne emulsified paints are extensively utilized in the building industry as outer sealants. Waterborne paints (latex paints) are paints that are articulated with water as the primary solvent, acting as a carrier for the solid material (adhesives, colorants, and preservatives). Waterborne acrylics generally contain up to 15% hydrocarbon liquids, which regulate the rheology and hydrophilicity of the paint.

These paints perform admirably in terms of reliability, waterproofing, and versatility. They are also simple, based on solitary constituents, and ready-to-use chemicals. Waterborne emulsion paints' characteristics are also constantly improving, extending their commercial usage.

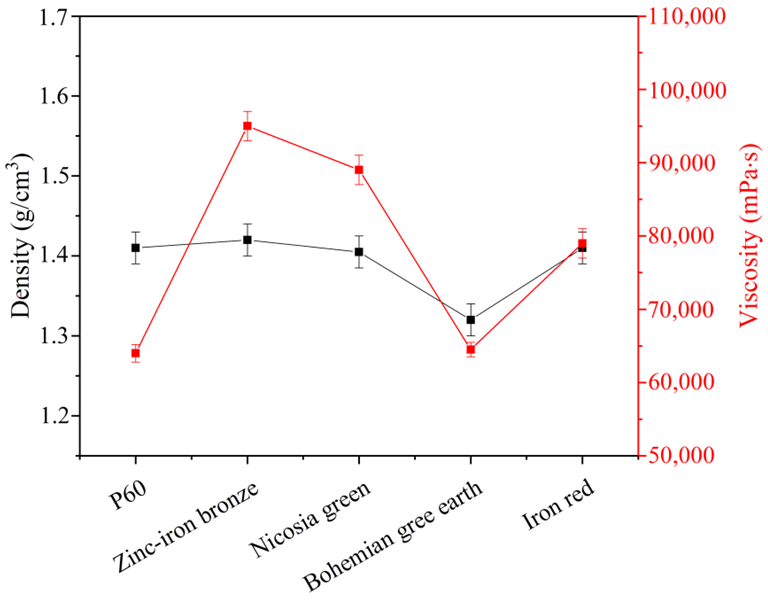

Effects of pigments on paint density and viscosity. Image Credit: Lisowski J et al., Materials

Addition of Colorants to Emulsion Paints

Waterborne emulsified varnishes are now available from most manufacturers in a variety of colors. Colorants are traditionally applied as dye slurry rather than dry pigments. If the dyes are not being used exorbitantly, this methodology guarantees that they have little influence on the protective layer characteristics.

However, such interventions do not actually decrease the paint's beneficial properties. In some areas, it can preserve or even enhance performance. There are numerous types of colorants, each of which affects more than just the color of the paint. The majority of research focuses solely on the characteristics that are thought to be altered by the colorant (or other additives).

What are Green Earth Pigments?

For hundreds of years, green earth has been utilized in pigments. It is a synthetic substance made from glauconite or celadonite mineral deposits. Both nutrients are silicon dioxide with a crystalline structure roughly comparable to mica and have a similar composition.

It is acid and alkali dissolvable and changes its appearance to dark brown when heated (burnt green earth). Light has no effect on the dye, and it is consistent with all other colorants. They are a more economical choice than other pigment molecules. The most common and popular pigments, cobalt greens, are among the most expensive, with prices ranging from $150 to $200 per kilogram.

Sample Preparation

The samples were produced by adding 5% w/w of each dye to the reference emulsified paint. The dyes were steadily incorporated into the specimens using a 1000 rpm rotational agitator. P60 is a non-toxic paint substance that was used in the standard specimen to balance the colorant intensity with the other samples.

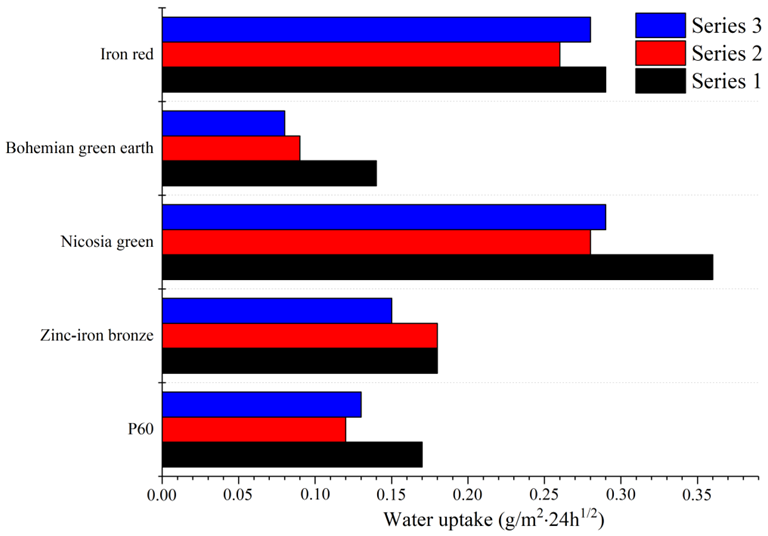

Water uptake after 24 h. Image Credit: Lisowski J et al., Materials

Research Findings

The pigments increased their viscosity significantly. The viscous characteristics enhancement ranged from 20% to 40% when contrasted to the conventional dolomite filler P60. Only the Bohemian earth dye had the same viscous attributes as the standard filler.

The inclusion of the dyes being researched had no significant effect on the wet-scrub tension of the paint. This implies that the dye granules were thoroughly slathered with the composite material, and the coating's outer layer remained stable in comparison to conventional synthesis. If any of the colorants tested disrupted the film formation, either mechanically or chemically, wet-scrub resistance would have decreased.

Bohemian green earth dye enhanced the paint's effectiveness by lowering uptake of water to the point of class III water absorption. This advancement could be attributed to small particulate material waterproofing some of the porous structure.

Which Color Additive Performed the Best?

Based on the findings, Bohemian green earth seemed the most superior and highly viable and promising coloration emulsifiers. The fact that it retained the very same level of rheological properties as the existing paint meant that it did not affect the paint's functional attributes.

Bohemian green earth did not change and even managed to improve some of the other attributes of the paint, such as moisture absorption, and transformed the dye into a fully functioning supplement.

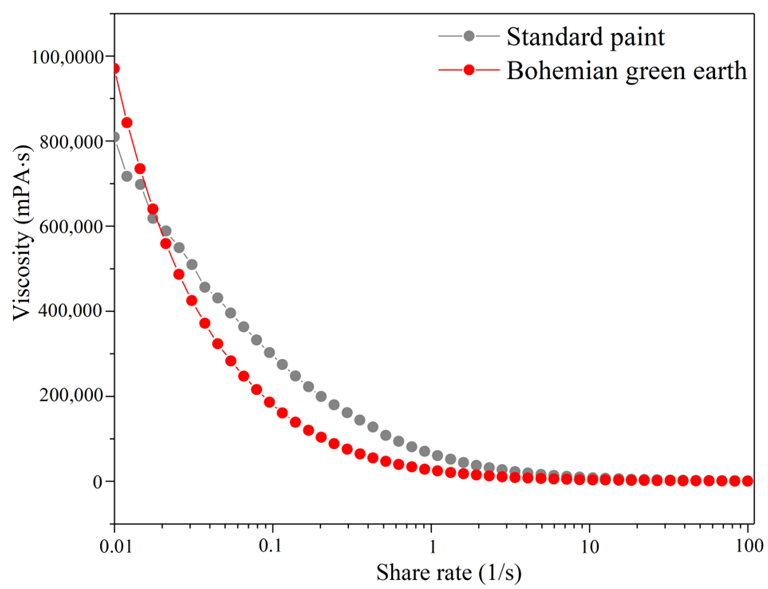

Following the selection of the highly advantageous pigment, a novel paint-optimized formulation with 5% weight material of Bohemian green earth was created. The customized paint had a significantly higher viscosity than the standard formulation, but it melted more quickly at low shear-rate values (0.01-1), implying that it might have less viscous behavior during storage.

Viscosity curves for the standard paint formulation and paint with bohemian green earth. Image Credit: Lisowski J et al., Materials

Benefits of the Study

Because green pigments are the most costly supplements, the trends discovered through additive research will provide a significant advantage for industrial applications. Nonetheless, any transition in the methodologies of commercial paints, particularly those relating to color, incur added expenses.

To summarize, the study has proved that each new addition to the existing formula should be analyzed to check its influence on the specific functional properties and potential advantages to paint quality.

Further Reading

Lisowski J, Szadkowski B, Marzec A. (2022). Effects of Selected Pigments on the Properties of Silicone Resin-Based Paints. Materials. 15(14). 4961. Available at: https://www.mdpi.com/1996-1944/15/14/4961

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.