In a paper recently published in the open-access journal Polymers, researchers studied the structural properties of multi-weft woven fabrics and their effect on the thermal protection and breathability of firefighting clothing. The generated results determined that the water vapor resistance was greatly influenced by the mass and the thickness of the fabric while the fiber content, thickness, and porosity had an influence on heat transmission.

Study: Thermal Protective Properties and Breathability of Multilayer Protective Woven Fabrics for Wildland Firefighting. Image Credit: Tyler Olson/Shutterstock.com

Background

Maximum thermal protection and minimal metabolic heat stress are the two most crucial parameters to be considered in the design of firefighting clothing suitable for outdoor fires. However, these two parameters are contradictory to each other, as high thermal protection fabrics have high stiffness and low breathability.

Presently, para-aramid and meta-aramid fibers have the most widespread applications in the making of thermal protective clothing due to greater thermal stability. Para-aramid fibers are commonly used for ballistic applications due to their high mechanical properties. Currently, the composite fabrics used in fire protection consist of multiple layers, providing high heat protection but simultaneously having low thermo-physiological comfort. Metabolic heat can increase in stressful firefighting conditions due to the mass, bulkiness, and stiffness of the firefighting clothing.

Therefore, firefighting clothing used in wildland firefighting must protect the firefighter from thermal radiation and reduce burn-injury hazards while being comfortable, light, breathable and porous. It must also be particularly permeable to gaseous sweat.

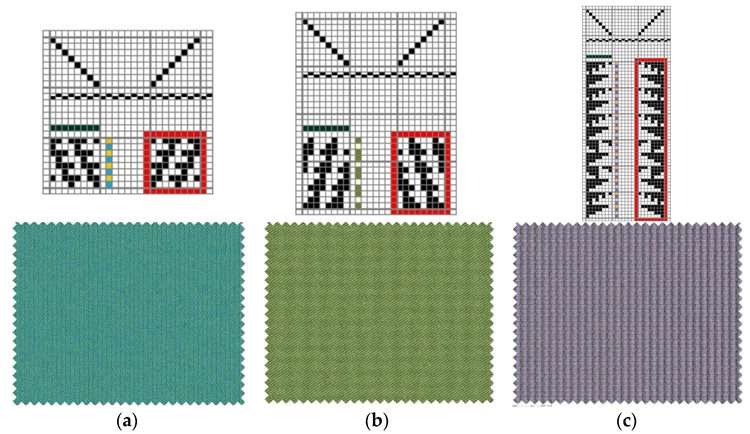

Peg plans and fabric simulation of samples (a) 2-weft; (b) 3-weft and (c) 4-weft. Image Credit: Kalazić, A et al., Polymers

About the Study

In this study, researchers aimed to enhance the comfort characteristics of firefighting fabrics without forfeiting user protection by investigating the impact of mass, fabric thickness, fiber content, and porosity on the heat transfer and water vapor resistance of multi-weft woven fabrics.

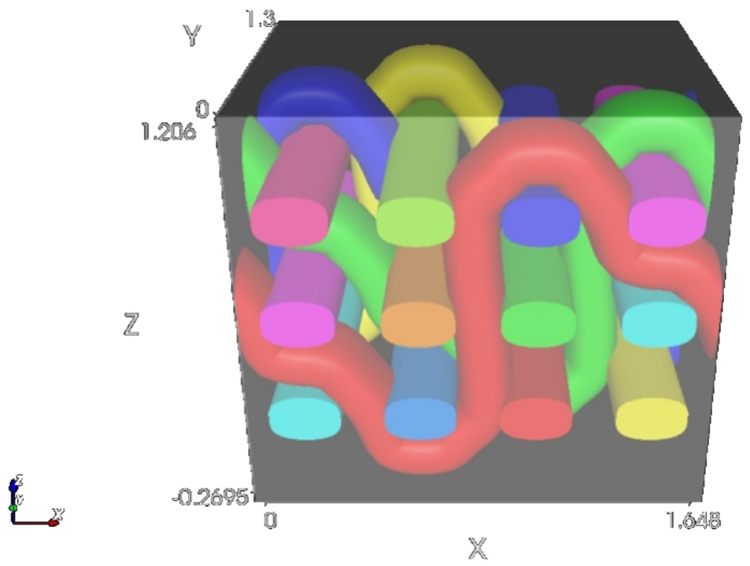

Researchers used eight fabric samples, which included one 2-weft, three 4-weft, and four 3-weft woven fabrics. The fabric samples were tested for their woven-fabric porosity using the Texgen program, wherein the samples were simulated to define several parameters such as weft and warp thickness, density, average fiber density, and fiber thickness.

The heat resistance tests were performed on a TE-08 radiant heat exposure tester, while the water-vapor resistance was tested by the sweating-guarded hotplate test under steady-state environments. Water-vapor resistance (Ret) was computed as the difference of a water-vapor pressure estimated between the surfaces of the material divided by the resulting evaporative heat flux distributed across a unit area.

Weave unit simulation in Texgen. Image Credit: Kalazić, A et al., Polymers

Observations

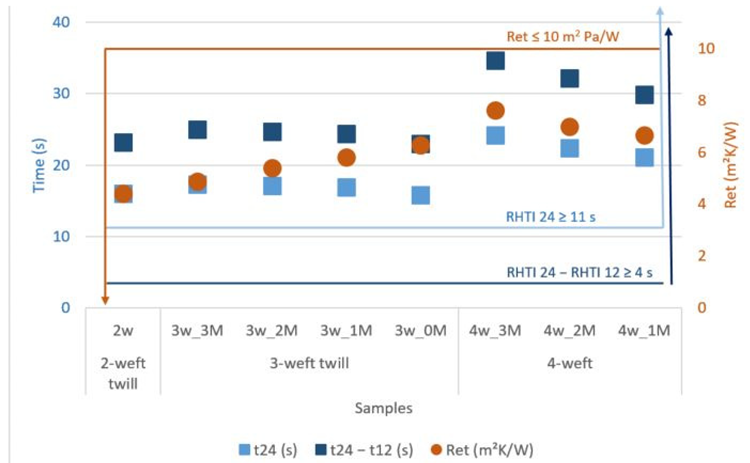

It was observed that the increase in the weft system numbers increased the fabric porosity. Due to the specific structure that results in greater flotation at every layer, the 4-weft fabrics exhibited the highest porosity volumes. Therefore, breathable woven fabric with efficient heat protective properties can be developed with an increase in the number of weft systems. Furthermore, volume porosity can be increased with an increase in the modacrylic/cotton yarn content.

The increased number of weft systems also increased the resistance to water-vapor passage. Consequently, this resistance also decreased with the decrease in the number of weft systems. Moreover, with an increase in the number of aramid fibers, the team noted an increase in the Ret with 3-weft fabrics, with a contrasting result observed for 4-weft fabrics potentially because of the distinct sample structures.

On the other hand, thermal radiation resistance was observed to be proportional to the weft system numbers. In comparison to aramid fibers, a higher Cotton Long Staple Combed/Modacrylic Sevel FRSA/L (MAC) content decreased the thermal resistance of the fabric. It was established that fabrics with a single aramid layer along with MAC had a better effect on heat protection.

Correlating the thickness and the mass of the samples with their water-vapor permeability resistance showed increased water-vapor resistance with an increase in the sample’s mass and thickness per unit of fabric area. Thus, with an increase in the weft systems and density, mass per unit area, porosity, and thickness, the resistance to water-vapor permeability increases along with a decrease in the heat transfer factor.

Comparison of the developed samples with the requirements of the standard. Image Credit: Kalazić, A et al., Polymers

Conclusions

To summarize, this research determined the impact on thermal protection and breathability by the use of multi-weft woven fabric materials in firefighting clothing. The heat transmission factor is largely affected by the proportion of modacrylic/cotton and aramid flame retardant (FR) fiber blends in the fabric layers. Although effective protection against heat radiation can be achieved with higher modacrylic/cotton FR content, the inclusion of aramid fibers in the outer layer is still necessary for protection against flames. Additionally, Ret was higher with greater sample mass and thickness.

According to the authors, the development of a comfortable woven fabric with optimal thermal protection is possible through the optimization of weft systems and the raw material combinations to utilize maximum use of modacrylic/ cotton FR into the fabric and minimum compromises against flame contact protection.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Kalazić, A.; Brnada, S.; Kiš, A. Thermal Protective Properties and Breathability of Multilayer Protective Woven Fabrics for Wildland Firefighting. Polymers 2022, 14, 2967. https://www.mdpi.com/2073-4360/14/14/2967