PPM Power is leading a consortium of UK companies to develop a supply chain for power systems based on embedded Gallium Nitride (GaN) devices. The project is funded by Driving the Electric Revolution, an ISCF Challenge delivered by UK Research and Innovation.

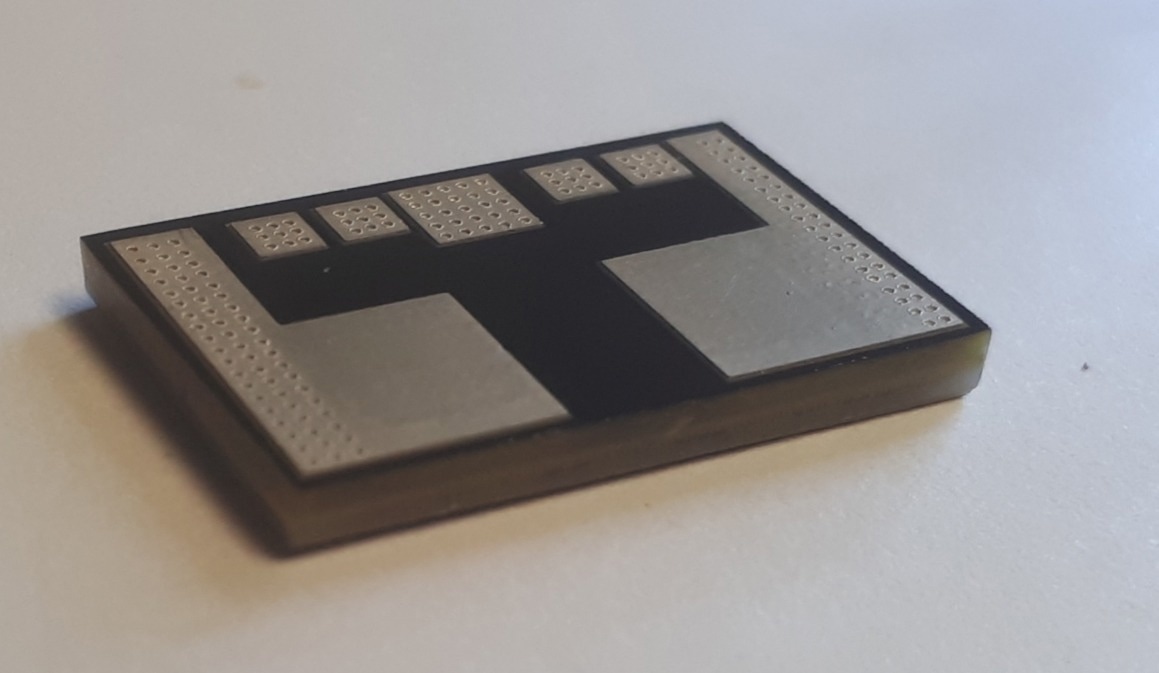

Embedded half bridge modules. Image Credit: PPM Power

Embedded half bridge modules. Image Credit: PPM Power

The consortium includes: RAM Innovations, Camutronics, TTPi and the Compound Semiconductor Applications Catapult.

Known as “P3EP” (Pre-packaged Power Devices for PCB Embedded Power Electronics) the project will leverage the performance advantages of Gallium Nitride (GaN) while delivering practical solutions that meet the integration and scalability needs of the industrial, automotive and aerospace industries.

The new supply chain will allow PEMD (Power Electronics, Machines & Drives) manufacturers to build converters with the highest power densities and allow UK power semiconductor companies to enter these markets.

Project lead, Joe Petrie - Strategic Marketing Manager at PPM Power - explained: “We are reducing power converters in size and weight by up to 10x compared to existing silicon-based designs. That has a big impact potential for applications such as automotive power management, the electrification of aerospace, and industrial applications such as motor drives and the power systems for robotics.”

Phil Surman, PPM Power Sales Director, said: “PPM Power is bringing the widest view possible of the high performance power electronics market; interpreting end user requirements and delivering insights that will enable the project to impact as quickly as possible.”

The project will last for 34 months.

Project Objectives

Industry drive for more efficiency, smaller size and lower weight products means sectors such as automotive, aerospace and industrial can benefit from module-based solutions that can be used in existing production lines and are available in volume.

The P3EP project is helping to meet the needs of OEMs and systems integrators by enabling a reliable, robust supply chain of leading-edge, wide-band-gap semiconductor-based power modules that can be ramped up to production level quantities.

Based on embedding pre-packages, the supply chain will enable more compact and lightweight power conversion modules that draw on the very high switching speeds and increased efficiencies that GaN can deliver. Power conversion modules that are up to 10x smaller than those using conventional silicon transistors become possible.

The potential of GaN to boost conversion efficiencies and increase power densities is widely acknowledged. The P3EP project allows PEMD manufacturers to leverage the radical advantages of embedded GaN without having to become experts in embedding technology and processes.

The Benefits of Embedding GAN

The project will overcome limitations caused by existing packaging supply chains. By avoiding the use of conventional packages with wire bonds, parasitic losses are drastically reduced. Bond wires cause stray inductances and capacitances and increase losses. Dissipation of heat will be improved, thus leading to greater operational reliability.

Embedded GaN pre-packages enable 3D integration which further improves design compactness; supporting faster switching, lower losses and efficient heat extraction as well as increased robustness.