In a paper recently published in the journal Polymers, researchers aimed to develop an active polyvinyl alcohol (PVA) and corn starch-based thermoplastic starch (TPS) film to be used in food packaging equipped with the antioxidant and antimicrobial properties of watermelon rind extract combined with a glycerol plasticizer. Consumer testing of the film determined favorable user acceptance.

Study: Active Thermoplastic Starch Film with Watermelon Rind Extract for Future Biodegradable Food Packaging. Image Credit: Girlgirl/Shutterstock.com

Background

With an annual global consumption of over 200 million tons every year, plastic usage has seen about a nine percent annual growth, with food packaging constituting more than half the amount. Since most of the food packaging is used only once, these non-biodegradable and non-recyclable packaging wastes create drastic terrestrial as well as aquatic environmental problems.

Casting the PVA/ST/WMRE film (a) and analysis of the mechanical property of the film on the texture analyzer (b). Image Credit: Todhanakasem, T. et al., Polymers

Therefore, there is an ever-growing need to develop food packaging that would meet environment-friendly benchmarks, have better degradability, and also minimize food loss while maintaining the food product quality. The technology for developing such packaging is termed active food packaging, which can be prepared using biopolymeric substances infused with active natural ingredients functioning as antioxidants, oxygen and ethylene scavengers, moisture absorbers, and antimicrobials.

Watermelon rind has significant antioxidant properties exhibited after extraction of ethanol, where the existing bioactive compounds inhibit potential free radical damage. It is also known to contain antimicrobial compounds. Furthermore, a synthetic polymer such as PVA is highly capable of forming transparent films, with greater sealing abilities and high thermal and mechanical stabilities. It is also degradable in composting environments. However, the fragility of PVA requires a plasticizer to increase its stability.

Although the addition of starch to PVA films has been seen to improve their mechanical properties and water molecular resistance, there has been a push in recent times to replace synthetic polymers with TPS for use in food packaging. TPS films are known to have low oxygen permeability and to be colorless, odorless, and transparent.

About the Study

In this study, the team performed watermelon rind extraction from dried rind powder by an incubator shaker. Two PVA films with corn starch and plasticizer were created, with the control film labeled PVA/ST and the film with the watermelon rind extract (WMRE) labeled PVA/ST/WMRE.

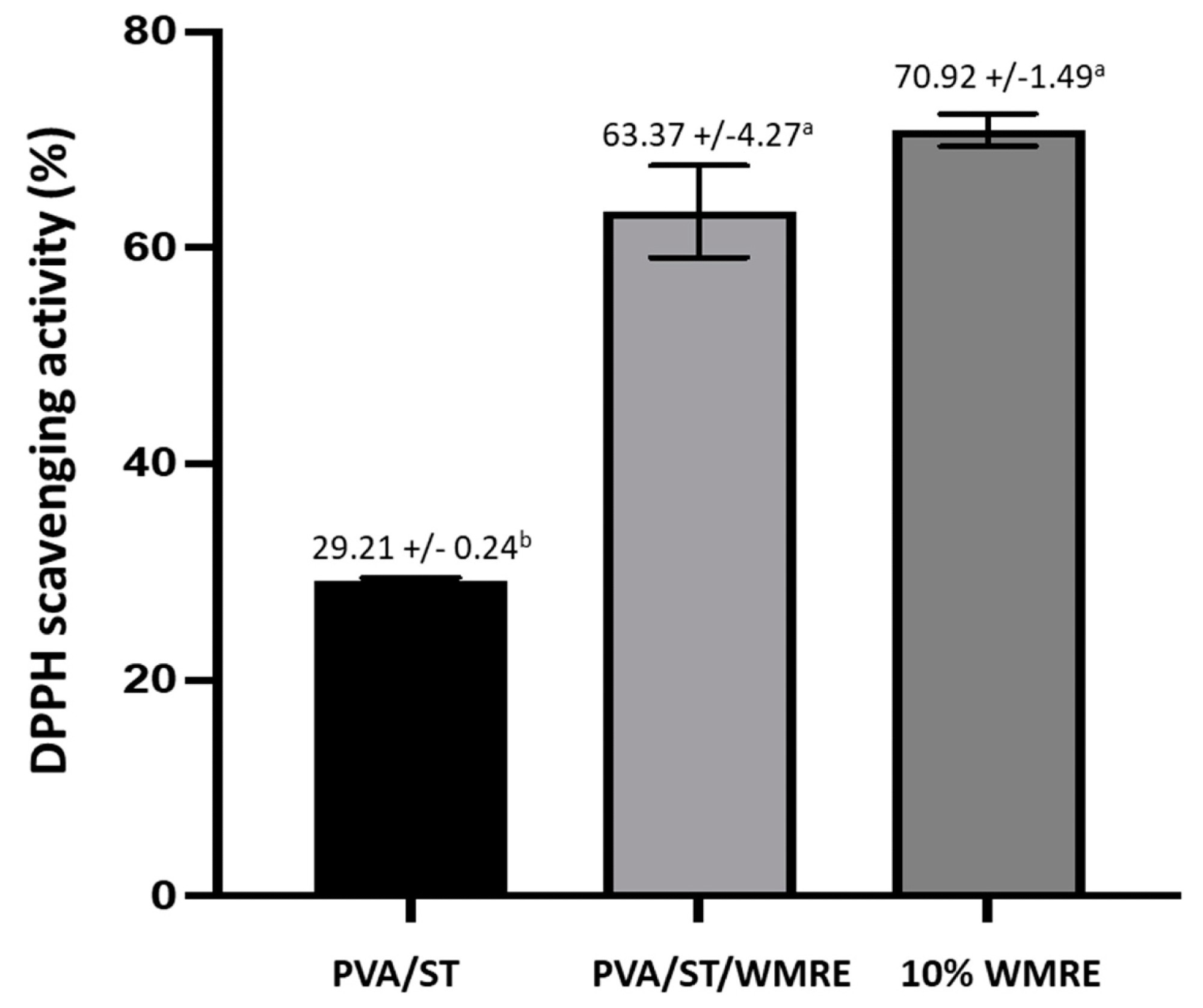

DPPH scavenging activity of PVA/ST, PVA/ST/WRE, and 10% v/v watermelon rind extract. The different letters represent a significant difference of p < 0.05. The error bar indicates the standard deviation (n = 3). Image Credit: Todhanakasem, T. et al., Polymers

The films were characterized on the basis of their thickness, water vapor permeability (WVP), tensile strength (TS), and the percent elongation at break (%EAB). The antioxidant activity was evaluated using the methanol-2,2-diphenyl-1-picrylhydrazyl (DPPH) radical scavenging activity, while the antimicrobial properties were tested by observing the microbial count on freshly cut purple cabbage wrapped with the films under storage.

The quality of the stored cabbage was further assessed by 50 consumers and rated on a nine-point hedonic scale. Lastly, the films were studied for their biodegradation behavior over a 35-day burial test.

Observations

The PVA/ST/WMRE films had a uniform thickness but did not differ from PVA/ST, indicating no effect of WMRE on the thickness of the film. Moreover, the stress-strain curves of both films exhibited plastic deformation. While the %EAB of PVA/ST/WMRE did not differ significantly from that of PVA/ST, the TS was higher. This was hypothesized to be due to the alteration in the biopolymer arrangement.

Furthermore, the negligible difference between the WVP of both films indicated that the addition of WMRE did not affect the film’s hydrophobic nature. The DPPH scavenging activity of PVA/ST/WMRE was slightly reduced as compared to the control film but the differences were insignificant. The purple cabbage’s microbial counts for both the films were initially similar. However, the PVA/ST/WMRE film was more effective in microbial growth inhibition after three days.

Additionally, the consumer preference testing showed significantly higher liking scores for the cabbage wrapped in PVA/ST/WMRE on days one, two, and three. Overall, the wraps with PVA/ST/WMRE scored the highest in consumer preference as compared to the rest of the food packaging methods.

Moreover, there was no significant difference in the biodegradability of the watermelon rind wraps as compared to the control film. Post 35 days of burial, 10.21% of PVA/ST and 12.6% of PVA/ST/WMRE were degraded.

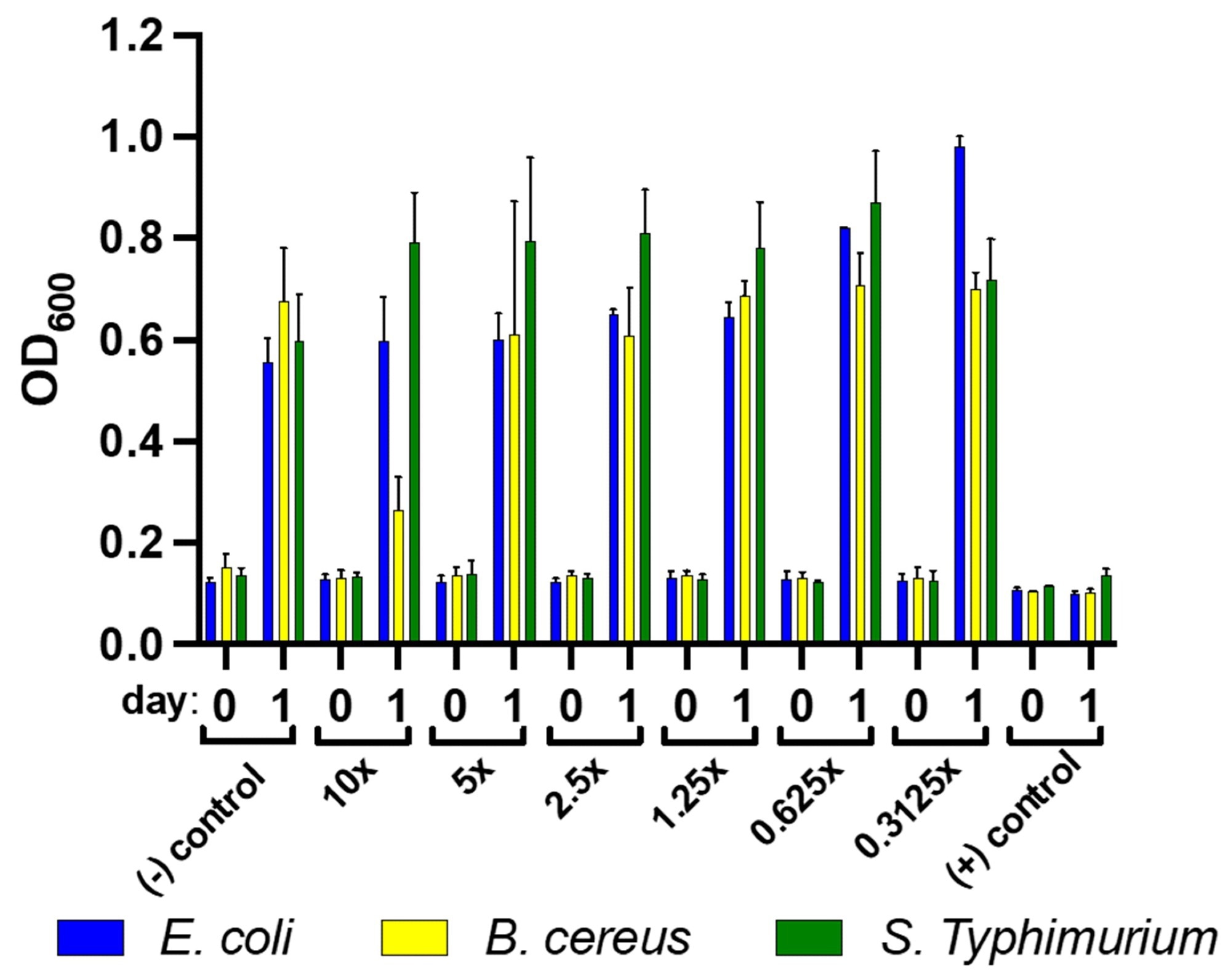

Antimicrobial properties of watermelon rind extract in 96-well plates at concentrations from 10–0.3125% against B. cereus, E. coli, and S. enterica subsp. enterica serovar Typhimurium when incubated at 37 °C for 24 h. The growth was monitored at OD600 using a microplate reader spectrophotometer. The error bars indicate the standard deviation (n = 3). Image Credit: Todhanakasem, T. et al., Polymers

Conclusions

To summarize, the team determined that the addition of WMRE to TPS along with excessive glycerol plasticizer can improve the TS, WVP, and %EAB of the biofilm. This study also exhibited increased antioxidant and antimicrobial activity against food-borne pathogens.

Although the film had no impact on the tested vegetables’ sensory attributes, the higher biodegradability indicated minimal environmental impact while aiding in food wastage mitigation and shelf-life extension. According to the authors, TPS with WMRE as active food packaging can be advantageous in the food industry for extending the food’s shelf life while reducing loss.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Todhanakasem, T. et al. Active Thermoplastic Starch Film with Watermelon Rind Extract for Future Biodegradable Food Packaging. Polymers 2022, 14, 3232. https://doi.org/10.3390/polym14163232