Sawing, carving, bending, or pressing are commonly used to create wooden items. Researchers explain how complex 3D structures can be created by programming flat wooden shapes extruded by a 3D printer to self-morph. In the future, furniture or other wooden products that could be delivered flat to a location and then dried to take on the correct final shape could be made using this process.

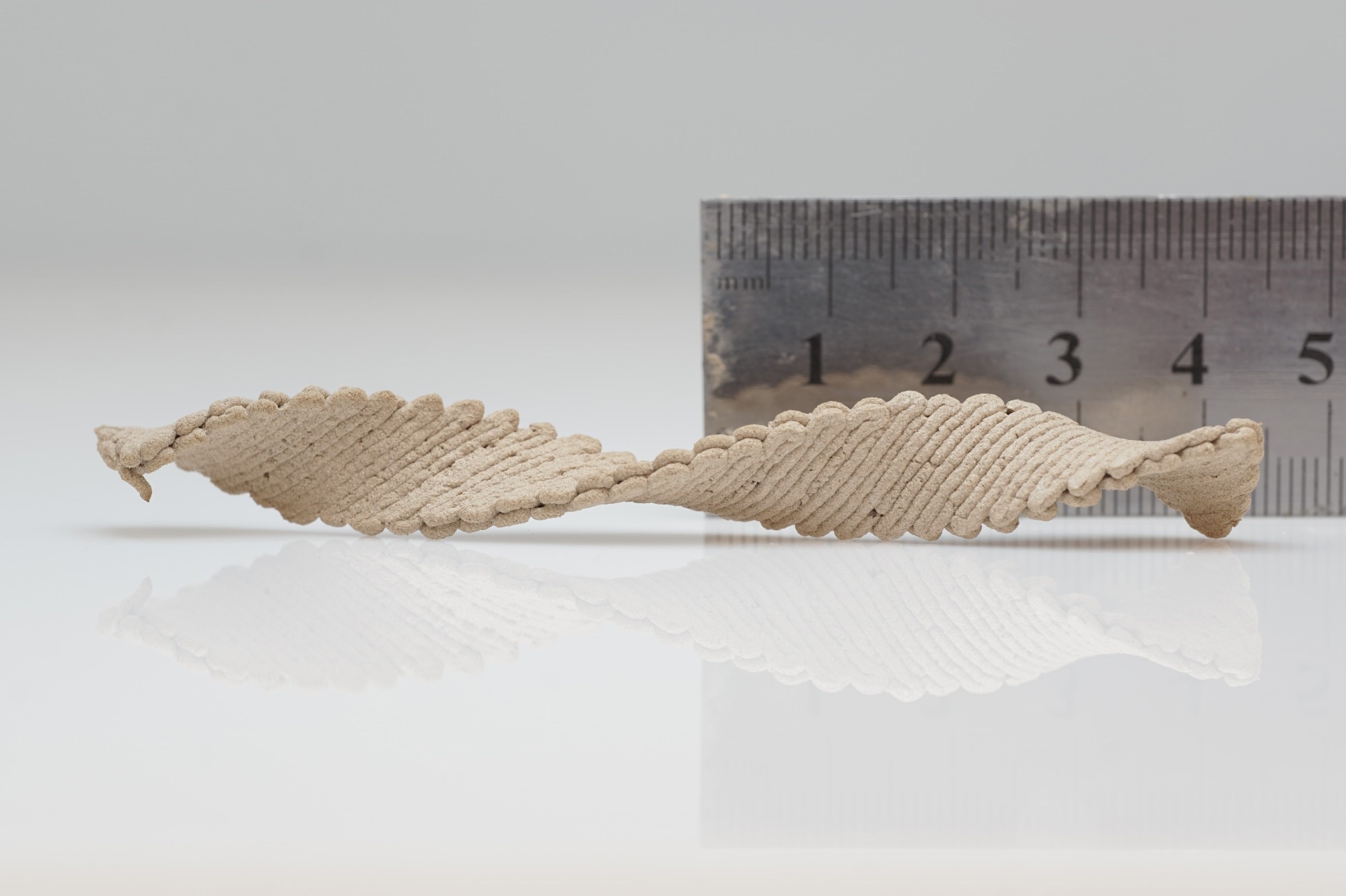

Wood ink printed as a flat rectangle is programmed to form a complex shape after drying and solidifying. (Ruler is marked in centimeters.) Image Credit: Doron Kam.

Wood ink printed as a flat rectangle is programmed to form a complex shape after drying and solidifying. (Ruler is marked in centimeters.) Image Credit: Doron Kam.

The researchers will present their findings at the American Chemical Society’s (ACS) fall meeting. ACS Fall 2022 is a hybrid conference that will be held online and in person from August 21 to 25, with on-demand access available from August 26 to September 9. Nearly 11,000 talks covering a wide range of science issues are included in the meeting.

In nature, plants and some animals may change their own shapes or textures. The wood from a tree can change shape as it dries, even after it has been cut down. Because of variances in fiber orientation inside the wood, it shrinks unevenly and warps.

Warping can be an obstacle, but we thought we could try to understand this phenomenon and harness it into a desirable morphing.

Doron Kam, Graduate Student, Hebrew University of Jerusalem

Doron Kam is presenting the research at the meeting.

Artificial constructions normally cannot shape themselves, in contrast to some natural items, according to Eran Sharon, Ph.D., one of the project’s key investigators. However, Sharon notes that researchers have recently started printing flat sheets that might transform into 3D structures in response to stimuli like moisture content, pH, or temperature changes.

However, he points out that the materials used to create these self-morphing sheets were synthetic, including gels and elastomers.

“We wanted to go back to the origin of this concept, to nature, and do it with wood,” adds Sharon. Sharon and Kam—as well as Shlomo Magdassi, Ph.D., and Oded Shoseyov, Ph.D., the other principal investigators who undertook this challenge with Ido Levin, Ph.D., who was a graduate student at the time—are at The Hebrew University of Jerusalem.

Ink made of wood waste microparticles, or “wood flour,” combined with cellulose nanocrystals and xyloglucan, two naturally occurring binders derived from plants, was created by researchers a few years ago.

The scientists then started printing 3D objects with ink. They recently found that the morphing behavior as the moisture content evaporates from the printed piece is dictated by the way the ink is put down or the “pathway.”

For example, a flat disk printed as a series of concentric circles shrinks and dries to form a saddle-like structure that resembles a Pringles® potato chip, while a disk printed as a series of rays radiating from a central point transforms into a dome or cone-like structure.

The team discovered that altering print speed can also influence the final shape of the product. This is due to the fact that shrinkage happens perpendicular to the wood fibers in ink, and print speed alters how aligned those fibers are. As a result of the particles’ more erratic orientation at a slower rate, shrinking happens in all directions. Since the fibers are aligned with one another during faster printing, the shrinkage seems to be more directional.

To produce a variety of final shapes, the scientists learned how to program the print speed and pathway. After drying, they discovered that stacking two rectangular layers that were printed with different orientations results in a helix.

In their most recent research, they discovered that they could program the printing method, pace, and stacking to determine the precise direction of shape change. For example, they can decide whether rectangles would twist into a helix that spirals in a clockwise or counterclockwise orientation.

With more acuity, the group will be able to mix saddles, domes, helices, and other design elements to create items with intricate final shapes, like a chair. Eventually, it might be feasible to create wood items that are delivered to consumers flat, which could lower shipping volume and costs.

Then, at the destination, the object could warp into the structure you want.

Doron Kam, Graduate Student, Hebrew University of Jerusalem

In the future, Sharon believes, it would be possible to license the technology for personal use so that users could create and print their own wooden objects using a standard 3D printer.

The team is also looking at the possibility of making the morphing process reversible.

We hope to show that under some conditions we can make these elements responsive—to humidity, for example—when we want to change the shape of an object again.

Eran Sharon, Study Principal Investigator, Hebrew University of Jerusalem

The Israeli Ministry of Science, Technology, and Space provided funding to the researchers.