By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Sep 28 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Sep 28 2022In an article recently published in the open-access journal Polymers, researchers presented an experimental study on the bonded anchorage of pre-stressed strands of carbon fiber-reinforced polymer (CFRP).

Study: Experimental Research on Bonded Anchorage of Carbon Fiber Reinforced Polymer Prestressed Strands. Image Credit: prapann/Shutterstock.com

Background

Due to the improvement of the global economy and the quickening of infrastructure development, bridges have greatly increased in number. However, the pre-stressed strands for girder bridges typically comprise corrosion- and fatigue-resistant steel materials. The steel strands frequently exhibit fatigue degradation, which causes significant financial losses.

Fiber-reinforced polymer (FRP) has steadily gained prominence in the field of civil engineering over the past few years. CFRP is the most used FRP and has been applied in a variety of industries. The anchoring problem has always been the primary influencing element that hinders the widespread use of CFRP bars and CFRP strands, despite significant advancements in applied research for CFRP bars and CFRP strands.

Another successful technique for securing the CFRP tendon with high anchoring efficiency is the wedge-bonding composite anchoring system, which combines the clip and bonding anchorage. Additionally, research showed that sand coating could enhance FRP's bonding capabilities even more. Few studies have been conducted on the internal taper changes of CFRP pre-stressed strand anchors and the impact of various bonding media on the anchoring performance of anchors, even though numerous academics have conducted extensive research on the anchorage system of CFRP strands.

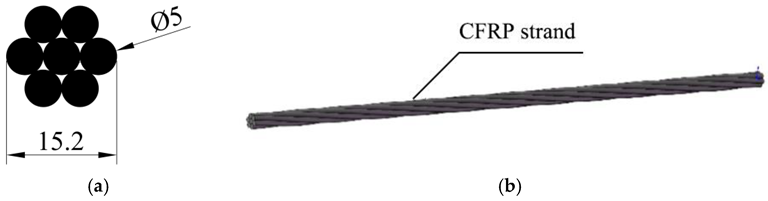

Cross-sectional dimensions of CFRP strands for testing. (a) CFRP strand section; (b) CFRP strand for testing. Image Credit: Jia, L et al., Polymers

About the Study

In this study, the authors used a CFRP strand with improved corrosion resistance and fatigue resistance in concrete structures to address the issues of a significant amount of corrosion and fatigue damage of the current pre-stressed steel strands. CFRP tension members were anchored using the bond anchoring, which bonded the CFRP through the binding medium.

The inner taper of the CFRP pre-stressed strand cone was anchored by an experimental study on the CFRP strand bond anchoring, and the effect of various anchor lengths and bonding agents on the anchorage performance was identified. The test results showed that the conical anchorage's taper was a significant element impacting how well it anchored and that the increase in the inner taper within a specific range could help the conical anchorage perform better.

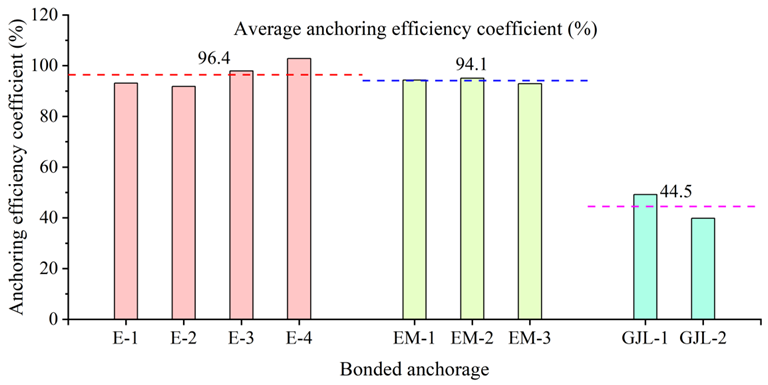

The team demonstrated that the most dependable and effective bonding anchorage for CFRP pre-stressed strands was a 200 mm anchor since it had the biggest taper. The 200 mm anchor's average anchoring efficiency coefficient was 96.4%, which was correspondingly 3.7% and 2.6% higher than the averages for 220 mm and 250 mm anchors. When epoxy resin mortar was utilized as the bonding medium, the anchor's anchoring effectiveness was 94.1% high. The overall comprehensive performance of the anchor could be increased once a suitable quantity of quartz sand was added to the epoxy resin, as could the stress of the CFRP strand.

The researchers elaborated that when employed as the anchor bonding medium, ultra-high-performance concrete dry mix (UHPC-GJL) only had an average anchoring efficiency coefficient of 44.5%, which made it unsuitable for coupling with CFRP strand materials. The CFRP material's properties were fully taken into account and converted into stranded wire. Based on this, a bond-type anchorage test with improved fatigue performance was conducted. First, by the anchoring of various lengths while pouring the same adhesive medium, experimental work on the performance of the bonded CFRP pre-stressed strand provided the development of adhesively bonded anchors with higher performance.

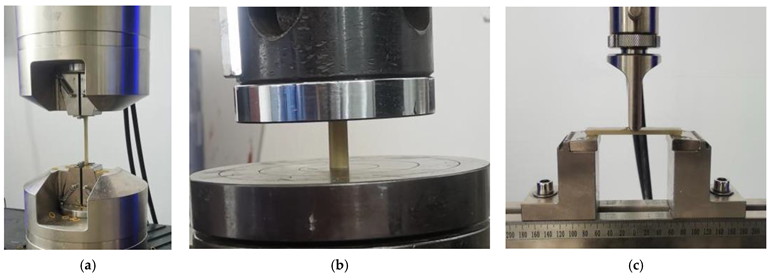

The effects of several bonding materials, including epoxy resin mortar, epoxy resin, and ultra-high-performance concrete dry mix (UHPC-GJL) on anchorage performance were then investigated using the best anchors. The necessary anchors and bonding media for the conical anchor were created.

Epoxy resin and epoxy resin mortar material property test. (a) Tensile test; (b) compression test; (c) bending test. Image Credit: Jia, L et al., Polymers

Observations

Due to the biggest taper, CFRP pre-stressed strand bonded anchorage with a 200 mm anchor was the most effective. The 200 mm anchor's average anchoring efficiency coefficient was 96.4%, which was correspondingly 3.7% and 2.6% higher than the averages for 220 mm and 250 mm anchors. This demonstrated that the taper was the primary element influencing how well this anchor anchored. The most reliable anchorage method for the CFRP strand was the one that bonded it to a 200 mm anchor since all of the specimens showed consistent failure modes and reduced variation in anchoring efficiency.

On the other hand, at 18.1% and 12.1%, respectively, the difference in the anchoring efficiencies among the specimens of 250 mm and 220 mm anchors was significant. All CFRP strands were explosively destroyed, and the anchoring efficiency was better when epoxy resin mortar was utilized as the bonding medium of the 200 mm anchor. There was also less variation in the anchoring efficiencies between the specimens.

Given that the stress-strain curves of every wire for the anchor with the epoxy resin mortar medium had a small degree of dispersion and were consistently constant before the peak value, and that the force of every wire of the CFRP strand was relatively uniform, the addition of a suitable amount of quartz sand to the epoxy resin aided the performance of the bonding medium as well as the anchoring of the CFRP strand.

Both the epoxy resin and the epoxy resin mortar could connect the CFRP strand securely; however, the epoxy resin anchor had the best anchoring efficiency. The epoxy resin mortar anchor had a higher overall anchoring performance than the epoxy resin anchor. The anchoring performance of the anchor and the bonded anchorage of the CFRP pre-stressed strand with the UHPC-GJL bonding medium were both at their worst. The CFRP strands were completely pulled out, and the average of the anchoring efficiency coefficient was the lowest, at 44.5%.

Comparison of anchoring efficiency coefficients of different bonding medium. Image Credit: Jia, L et al., Polymers

Conclusions

In conclusion, this study determined how well the bonded anchorage of CFRP pre-stressed strands performs through thorough experimental research.

To determine the best-bonded anchorage for CFRP pre-stressed strands, experimental research was conducted on the effects of various anchor lengths and bonding material on anchorage performance.

References

Jia, L., Wang, B., Tafsirojjaman, T., Experimental Research on Bonded Anchorage of Carbon Fiber Reinforced Polymer Prestressed Strands. Polymers, 14(19), 4015 (2022). https://www.mdpi.com/2073-4360/14/19/4015

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.