A new paper published in the journal Materials has investigated strategies for characterizing visible parylene films, which have applicability as advanced coatings for various devices. The research has been conducted by a team of scientists from Korea and Canada.

Study: Optical and Electrical Characterization of Visible Parylene Films. Image Credit: StudioMolekuul/Shutterstock.com

Parylene Films: An Overview

High-quality thin films are required in several technological applications, such as micro-electromechanical systems, biomedical devices, optical devices, sensors, and flexible electronic devices. These films must be resistant to cracking and peeling, requiring the use of robust, high-quality materials in their construction.

Parylene (poly-para-xylene) is a polymer that has garnered interest from researchers in recent years for use as a thin film for a variety of applications. This polymer can produce films with uniform thicknesses, even on complex structures or those with defects such as fine cracks.

This material has several beneficial properties for a number of uses, including electrical resistance, chemical resistance, and gas barrier properties. Due to its gas barrier properties, the use of parylene as a coating film can extend the life of devices.

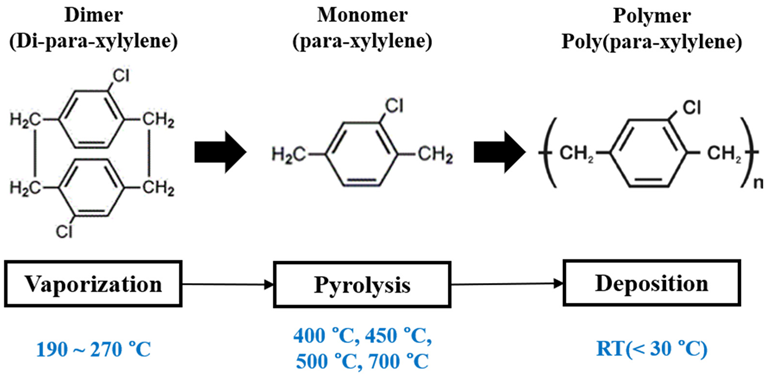

Molecular structure and schematic mechanism for the chemical vapor deposition process of visible parylene-C. Image Credit: Lee, Y-S et al., Materials

Properties such as its high resistivity, smooth surface, and flexibility have made parylene an ideal candidate for applications such as flexible electronic device substrates and as insulating layers in transistors. Moreover, moisture resistance and pinhole-free characteristics have been leveraged by researchers to produce protective and encapsulation films from this polymeric material.

Parylene-C is a derivative of parylene, which has been explored as a transparent film. This derivative has a low deposition temperature and is compatible with standard micro- and nano-fabrication processes. Generally, chemical vapor deposition is used to form transparent parylene-C films.

Parylene film quality can be controlled during chemical vapor deposition processes by controlling parameters such as working pressure and evaporation temperature. Films with tailored properties such as light-scattering behavior can be produced by controlling low-temperature pyrolysis of sublimed parylene dimers. Several studies have investigated the production of functional high-quality parylene films.

The Study

Whilst there is a growing body of research on characterizing the optical properties of visible and transparent parylene films, such as their haze, there has been limited research on comprehensively characterizing their electrical, structural, and thermal properties.

The new study in Materials has investigated the optical, thermal, structural, and electrical characteristics of visible films. The authors tuned the pyrolysis temperature during chemical vapor deposition and analyzed the effect on the film’s properties. A pyrolysis temperature range of 400-700oC was used. The ratio of dimer to monomer gases was tuned by adjusting the pyrolysis temperature.

Commercially available parylene-C films were studied with a single-step room temperature fabrication process using chemical vapor deposition developed by the research team. Fourier-transform IR spectroscopy and X-ray diffraction were employed to analyze the properties of films. Atomic force microscopy was employed to image the surface characteristics of parylene films.

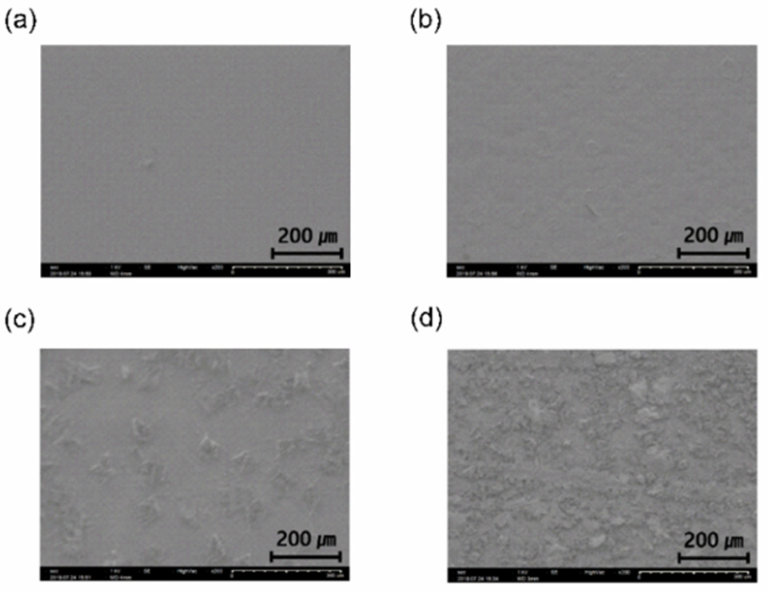

SEM images of the (a) P700 (b) P500 (c) P450 (d) P400 parylene films. Image Credit: Lee, Y-S et al., Materials

Study Conclusions

Controlling the pyrene dimer pyrolysis temperature produces films with high transmittance and haze. Fourier-transform IR spectroscopy and X-ray diffraction measurements confirmed the formation of visible parylene films due to dimer crystal presence in films.

In terms of thermal properties, the research unveiled that the film with dimer crystals possesses an enthalpy of melting of over 40 J/g. This was significantly more than polymer melts, which have an enthalpy of melting of 15 J/g. Structurally, the surface roughness values of different films produced under different pyrolysis temperature conditions were attributed to their degree of crystallinity.

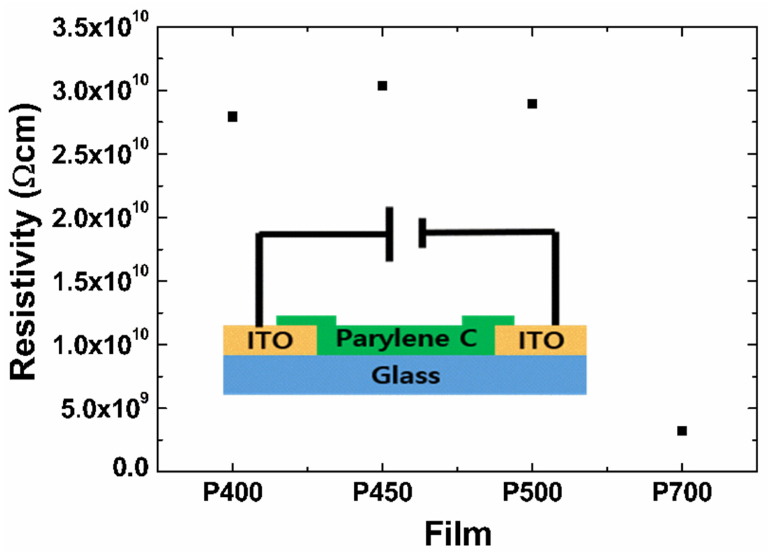

Optical measurements revealed that the reflectance of parylene films is influenced by their surface roughness, which is caused by dimer crystals. This results in the production of opaque films. Additionally, the research demonstrated that visible parylene films can be produced with good insulation performance and resistivity. The haze range of the prepared visible parylene films was 10-90%.

The authors have stated that the tailored, visible parylene-C films prepared in the study can be considered as advanced insulation coatings for use in various electronic devices and optical systems.

The specific resistance of the P700, P500, P450, and P400 parylene films. Inset: schematic structure of the device and the measurement setup. Image Credit: Lee, Y-S et al., Materials

In Summary

In summary, this research has helped to provide a comprehensive categorization of parylene film properties, which heretofore have not been sufficiently characterized by researchers. The optical, structural, thermal, and electronic properties of these commercially important polymers can be controlled by tailoring fabrication processes, with the study revealing the influence of pyrolysis temperature.

Overall, this research will have implications for the future of research into various technological fields such as biomedicine, optics, MEMs devices, and flexible electronics. Comprehensive characterization of parylene films will aid the future design of more efficient coatings for a plethora of advanced electronic devices.

Further Reading

Lee, Y-S et al. (2022) Optical and Electrical Characterization of Visible Parylene Films Materials 15(19) 6717 [online] mdpi.com. Available at: https://www.mdpi.com/1996-1944/15/19/6717.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.