By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Oct 18 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Oct 18 2022In an article recently published in the open-access journal Energy Technology, researchers presented a perspective on energy-efficient solvent-based lithium-ion battery (LIB) electrode production using innovative drying methods.

Study: A Perspective on Innovative Drying Methods for Energy-Efficient Solvent-Based Production of Lithium-Ion Battery Electrodes. Image Credit: P5h/Shutterstock.com

Background

One of the energy-intensive phases in the fabrication of LIBs is the drying process step. Industrial-scale drying of battery electrodes begins with covering a current collector foil with a wet film comprising particulate solvent dispersions using a slot-die method. Conventional convective drying hardens the layer as drying time passes while removing the solvent from the wet film. The variations in coating and drying times are caused by the various coating kinds and thicknesses as well as the ongoing advancement of system technology.

It is important to consider how the drying intensity affects the electrode's structure. It is impossible to increase drying intensity and the corresponding manufacturing speed without sacrificing electrode quality. No matter the electrode specifications, prolonging the dryer will boost throughput.

Handling very thin foils presents a challenge since they tend to wrinkle as dryer duration increases and put additional demands on the web tension controls. A thoughtfully planned combination of several drying techniques is advised to be able to boost production speeds and, thus, maximize throughputs. The combination of convective and infrared drying is currently the subject of scientific study. Additionally, the maximum efficiency and best quality electrode should be the targets to promote the sustainability of the drying process from the perspective of sustainable circular production. As a result, research on the battery process is increasingly focusing on new drying methods.

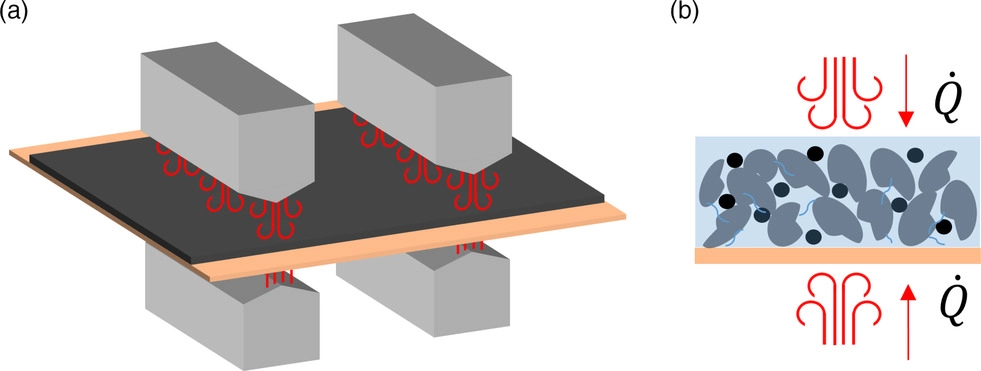

Convective drying: a) Nozzles blow heated air on the coating to be dried; b) introducing heat into the coating from above and transporting away the solvent. Image Credit: von Horstig, M-W et al., Energy Technology

About the Study

In this study, the authors discussed the demand for a smaller carbon footprint, energy efficiency, and lower production costs for LIBs for the development of cutting-edge electrode drying technologies that accelerate the drying process and deliver heat to the coating more effectively. This study provided a perspective on potential drying processes that were utilized in other industries and could be modified for the manufacturing of LIB electrodes.

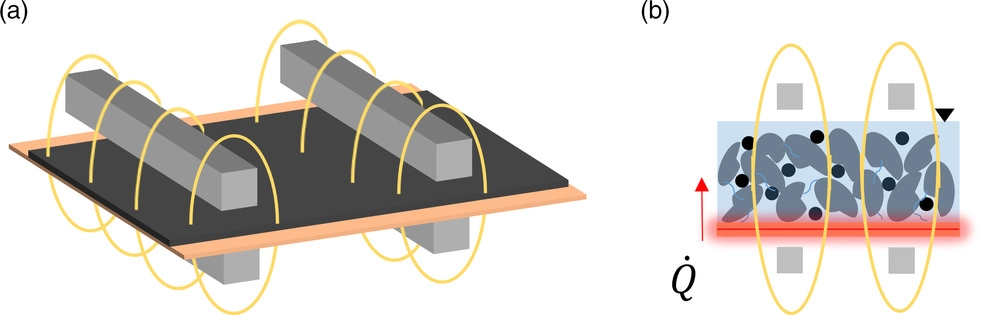

The team suggested a convective and inductive drying technology combination for simultaneous double-sided coating. A beneficial strategy to address the demand for quick and high-efficiency electrode drying was provided by the complementing heat introduction methods.

The researchers provided a brief explanation of the most promising drying technologies for battery process development. A cross-comparison of drying technologies was added, along with their difficulties, potentials, and technology readiness levels (TRL). A suggestion for a prospective amalgamation of several drying procedures was also made to enhance simultaneous double-sided coating.

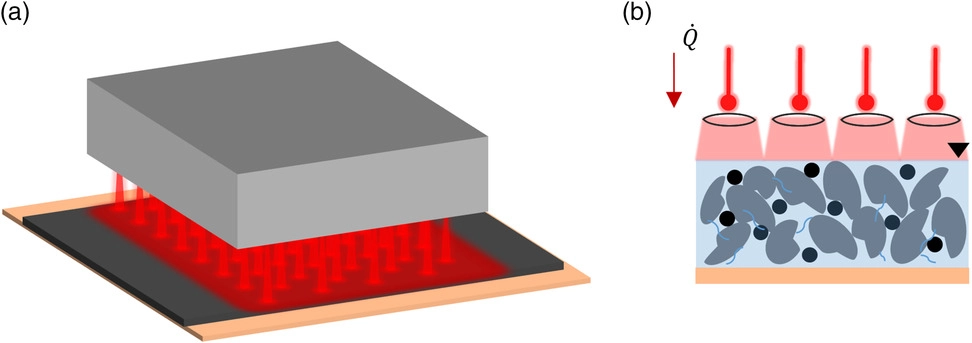

Laser drying: a) VSCEL-chips emit focused electromagnetic waves in the IR-spectrum. The beams are widened by zoom optics placed in front of the emitters, b) precisely introducing the heat into the coating to be dried. Image Credit: von Horstig, M-W et al., Energy Technology

Observations

Modern induction heating systems had heating efficiencies that could reach about 70%. For NMP-based cathodes, the drying speed in a pilot line electrode dryer with a length of 1 m was tripled. For water-based anodes, a five-fold increase in drying speed compared with solely convective drying was realized. There was a greater than 40% energy decrease. The ExLaLib project looked at the viability of VSCELs for laser drying. There, the energy required for electrode drying was cut in half utilizing a 2.9 kW module with roughly 873.2 Wh m-2 of the electrode.

The array efficiencies were no higher than 42%, and VCSEL chip efficiencies could reach up to 49%. In comparison to lab-scale oven drying, 450 W of laser power dried 50 cm2 s-1 with comparable mechanical and electrochemical properties while using roughly 50% less energy. The drying rate of this laser drying technology must be multiplied by 50 to achieve normal coating speeds of 50 m min-1 with web widths of 30 cm. When compared to drying on a pilot-scale convective drier, the electrical energy needed for cathode production was lowered by up to 85%, and for anode production, it was reduced by more than 60%.

The near-infrared (NIR)-emitters must be heated to extremely high temperatures of about 3000 K to produce short-wave radiation, which resulted in a higher energy output compared to mid-IR emitters.

In comparison to a high drying rate profile with coating surface temperatures of 90 °C in all three infrared-drying chambers, a moderate drying profile with climbing coating surface temperatures of 55, 65, and 75 °C produced a higher adhesion strength and improved electrochemical performance. While the efficiency of conversion of energy from electrical to radiant energy ranged from 70% to 90%, depending on the emitter technology, the drying process' effectiveness was mostly influenced by the emitted wavelengths of light and the material's absorptivity. The drying of the electrode coating and providing a dry atmosphere during cell assembly were the phases in the production of LIB that required the most energy.

Induction drying: a) induction coils generate an alternating electromagnetic field, b) which heats the current collector foil via inducing “eddy currents” in the material. The heat is transferred into the coating via heat conduction. Image Credit: von Horstig, M-W et al., Energy Technology

Conclusions

In conclusion, this study discussed the incorporation of energy into the electrode, improving energy efficiency and, consequently, lowering the energy need and CO2 emissions associated with electrode manufacture.

The authors mentioned that the proposed drying technologies are promising candidates to decrease the efficiency of cutting-edge drying processes since drying rates are a limiting factor in web speed that affects energy consumption.

They stated that adding additional heat through infrared dryers and/or induction coils offer the biggest advantages for the industry in terms of energy and cost reduction.

Reference

von Horstig, M-W., Schoo, A., Loellhoeffel, T., et al. (2022) A Perspective on Innovative Drying Methods for Energy-Efficient Solvent-Based Production of Lithium-Ion Battery Electrodes. Energy Technology. https://onlinelibrary.wiley.com/doi/10.1002/ente.202200689

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.