Metso Outotec is introducing yet another innovative plant concept, Flotation Plant Units, to its unique minerals processing portfolio. The solution provides unparalleled metallurgical performance by seamlessly integrating functional design with a comprehensive scope, leading to high operational reliability and a fast return on investment. Compared to the traditional delivery, Flotation Plant Units result in the earliest time-to-volume.

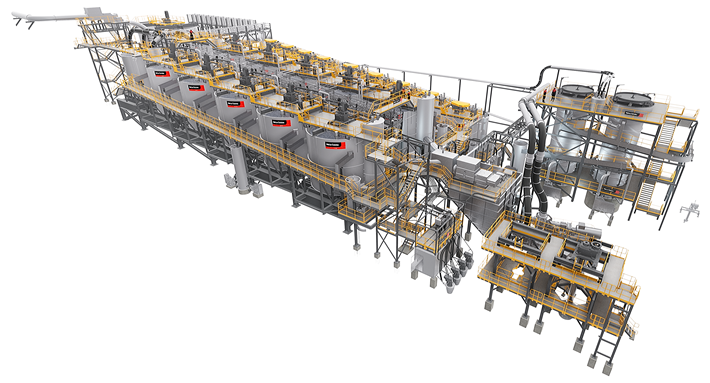

Metso Outotec Flotation Plant Unit. Image Credit: Metso Outotec

Metso Outotec Flotation Plant Unit. Image Credit: Metso Outotec

“In flotation, changing ore types can cause recovery losses, and poorly integrated plant equipment leads to underperformance. Maximizing overall performance and reliability requires in-depth understanding of the complex flotation circuit sizing. All these concerns have been taken into consideration in the design of the Metso Outotec modularized Flotation Plant Units to provide unmatched results. The plant units feature industry-leading technologies, which also include several Planet Positive solutions. The units consist of state-of-the-art flotation equipment, conditioners, froth handling systems, as well as automation and sophisticated services,” explains Tatu Miettinen, Product Manager, Flotation Islands at Metso Outotec.

Metso Outotec Flotation Plant Units offer unique benefits

- Integrates flotation circuit testing, piloting, and modeling capabilities from in-house test centers and modeling software into unrivalled flotation circuit design capabilities

- One-stop-shop from testing to full plant delivery

- Froth handling is designed for a high operational window, allowing for flexibility in circuit operation

- High emphasis on accessibility

- Maximized maintainability and froth visibility thanks to optimal pipe and cable routing, which keeps the top of the cells clear

- Safe, easy and representative process sampling

- Option to vary flotation circuit configuration online

More information on the Flotation Plant Units is available on our website.