Reviewed by Mila PereraOct 26 2022

A new type of semi-structural, degradable plastic based on wood may replace the plastics currently used in building and home furnishings.

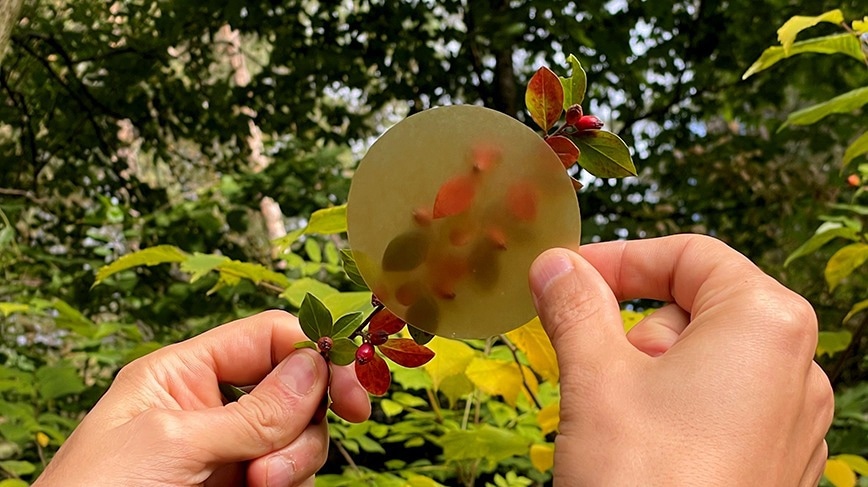

Peter Olsén, a researcher at KTH, holds up a sample piece of a new degradable plastic from wood. “These new materials, because of their high fiber content and degradable matrix, could be a game changer for a future circular material economy,” he says. Image Credit: Peter Olsén

Peter Olsén, a researcher at KTH, holds up a sample piece of a new degradable plastic from wood. “These new materials, because of their high fiber content and degradable matrix, could be a game changer for a future circular material economy,” he says. Image Credit: Peter Olsén

According to KTH researchers, unlike thermoplastic, the material can be decomposed without harming the environment.

Making materials robust enough to replace fossil-based materials used in house construction and furnishings, such as bathroom cabinets, doors, wallboards, and countertops, is one of the objectives of renewable wood composite development. Additionally, it must be circular or sustainable.

Degradability enables circularity. By degrading the plastic, the fibers can be recycled and the chemical components from the plastic reused.

Peter Olsén, Researcher, KTH Royal Institute of Technology

The strength of materials like fiberglass is primarily due to their high fiber content, but it is challenging to produce a degradable wood composite without experiencing significant heat damage from procedures like melt-compounding.

Olsén and colleagues at KTH claim to have discovered a method of delivering both high fiber content and degradability.

No one has been able to make a degradable plastic with fiber content this high before while having good dispersion and low fiber damage. This enabled the material properties to be improved dramatically compared to previous attempts.

Peter Olsén, Researcher, KTH Royal Institute of Technology

The researchers coupled polymer chemistry with a process technology such as carbon fiber composites to increase fiber content.

According to Olsén, everything is built upon accessible and inexpensive raw resources. The degradation byproducts can be recycled and are safe for the environment, permitting what Olsén refers to as “a fully circular product concept.”

Moreover, it could help conserve trees.

“It invites recycling of wood fibers to enable reformation of the material,” stated Olsén.

But Olsén states that the formula has to be improved before commercialization.

The key to the work is that it shows a new way of how we can create degradable bio-composites with high fiber content.

Peter Olsén, Researcher, KTH Royal Institute of Technology

Nature Communications published the findings.

The KAW Biocomposites project (grant 2018.0451 LAB), the Swedish Foundation for Strategic Research (grant FID15-0115 TL and LAB), and funding from Formas—a Swedish Research Council for Sustainable Development (Re-Design Plastic, 2020-01696 PO—provided assistance for the study.

Journal Reference

Oliaei, E., et al. (2022) Highly reinforced and degradable lignocellulose biocomposites by polymerization of new polyester oligomers. Nature Communications. doi:10.1038/s41467-022-33283-z.