Panacol has developed Vitralit® UD 4292 F, a new dual-curing adhesive that cures primarily by UV light with a secondary anerobic cure for shadowed areas. The special feature of this adhesive system is the high glass transition range of >130°C when cured under optimum conditions.

Vitralit® UD 4292 F. Image Credit: Panacol

Vitralit® UD 4292 F. Image Credit: Panacol

In response to a growing market demand for UV anerobic adhesive systems, Panacol has expanded its portfolio of dual-curing adhesive systems with Vitralit® UD 4292 F. This new product is ideally suited for structural bonding and sealing in automotive and electronics applications.

Vitralit® UD 4292 F is a transparent acrylic adhesive that cures in just a few seconds with light in the UVA or visible range. LED curing devices from Dr. Hönle provide light curing energy in wavelengths and intensity that optimize absorption by the adhesive’s photoinitiators for highly efficient UV light curing cycles. In shadowed areas, this adhesive reacts with metal ions in the absence of oxygen to ensure full cure. The secondary anerobic curing can be accelerated by adding heat or by applying a chemical activator to one of the surfaces to be bonded. When properly cured, Vitralit® UD 4292 F exhibits very high pull-out forces on various metals.

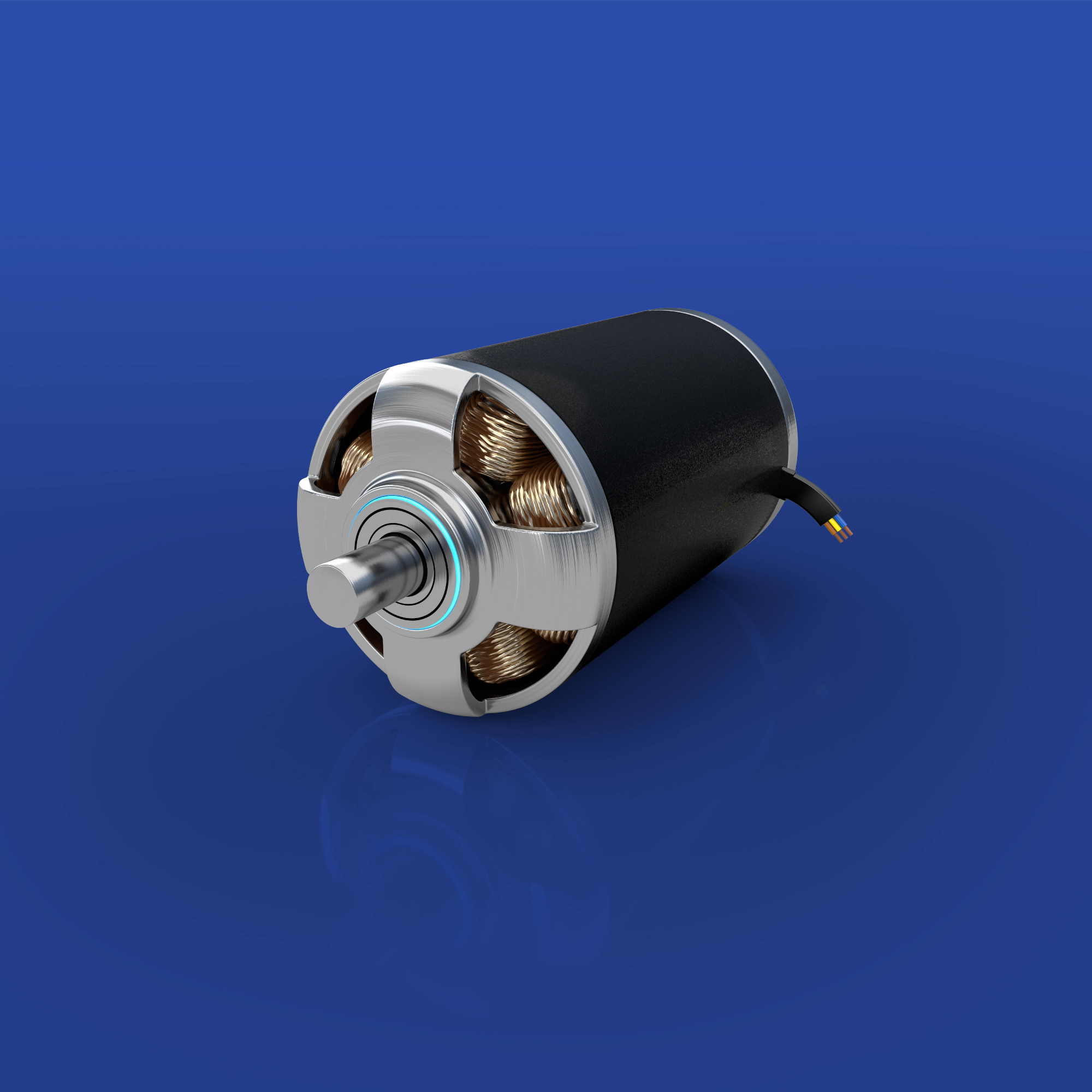

These properties make Vitralit® UD 4292 F particularly desireable for a wide variety of electric motor assembly applications, including structural bonding of ball bearings or shaft-hub connections on rotors and stators. The high glass transition temperature of over 130°C ensures that the adhesive system retains its bond strength under temperature fluctuations and dynamic stress. This UV anaerobic adhesive system meets the demanding assembly requirements in the electric motor and electric vehicle (EV) markets.

For visual process control, the composition of Vitralit® UD 4292 F contains a fluorescent marker that glows bright blue when exposed to low intensity UV light, making it visible in very thin gaps.