A new paper in the journal Polymers, authored by researchers from Brazil, has explored the use of two underutilized agricultural and food waste products, banana and bergamot peels, for use as biomaterials to produce rigid polyurethane biofoams.

Study: Rigid Polyurethane Biofoams Filled with Chemically Compatible Fruit Peels. Image Credit: G.Tbov/Shutterstock.com

Utilizing Food and Agricultural Waste to Produce Value-Added Products

The aims of the circular economy are to utilize waste streams to manufacture value-added products which can be used in multiple industrial sectors. This has the benefits of reducing both carbon emissions, saving virgin resources, and providing a route toward increased sustainability for human society.

Agricultural and food waste streams have been explored for multiple applications, producing sustainable and green products which have a vastly reduced carbon footprint. The size of the agricultural and food industries, which supply the growing global population, ensures the abundance of vital resources.

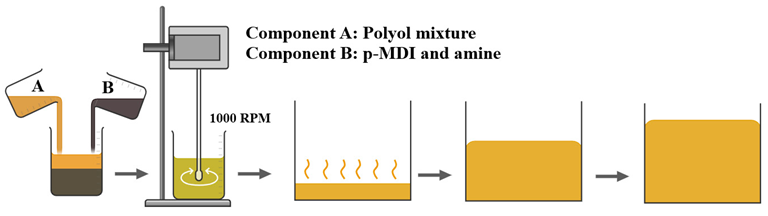

Schematic representation of the RPUF manufacturing. Image Credit: Acosta, A.P et al., Polymers

Improving the Sustainability of Polyurethane Manufacturing

Polyurethane is a widely used material in commercial applications such as insulation, adhesives, sealants, medium-density fiberboard, and bonded carpet cushions. This key industrial polymer is traditionally made from by-products of the petrochemical industry, and this production route is becoming increasingly unsustainable.

Worldwide, over $60 billion worth of polyurethane parts are consumed, with this figure predicted to rise to over $80 billion in the near future as demand increases. Polyurethane foam is a popular thermosetting plastic and is divided into three categories: rigid, semi-rigid, and flexible foams. This classification depends on the material’s crosslinking density and degree.

Rigid polyurethane foams are in huge demand due to their low thermal conductivity, closed-cell structure, low water absorption behavior, and enhanced compressive strength. Used in insulation, automotive parts, packaging, and refrigeration components, their properties are comparable to other insulation materials such as porous concrete, expanded polystyrene, and mineral wool.

However, despite its superior insulation properties, the high cost of this material hinders its widespread application as an insulation material, with much cheaper alternatives commercially available. Furthermore, the use of petrochemicals to produce polyurethane foams is problematic, as the oil industry has been linked to climate change, and global reserves are predicted to become severely depleted in the coming decades.

Therefore, there is an urgent need to improve the sustainability of the polyurethane industry and move away from traditional petrochemical production routes. In recent decades, the use of cost-effective and abundant bio-based materials such as fillers has become increasingly attractive.

Discarded fruit and vegetable biomass, which would otherwise go to landfill and therefore removed from the production chain, has a vast environmental appeal currently. This trend is reflected in the use of agricultural and food waste products in the production of several other polymer materials, such as polyvinyl chloride, polypropylene, and polylactide.

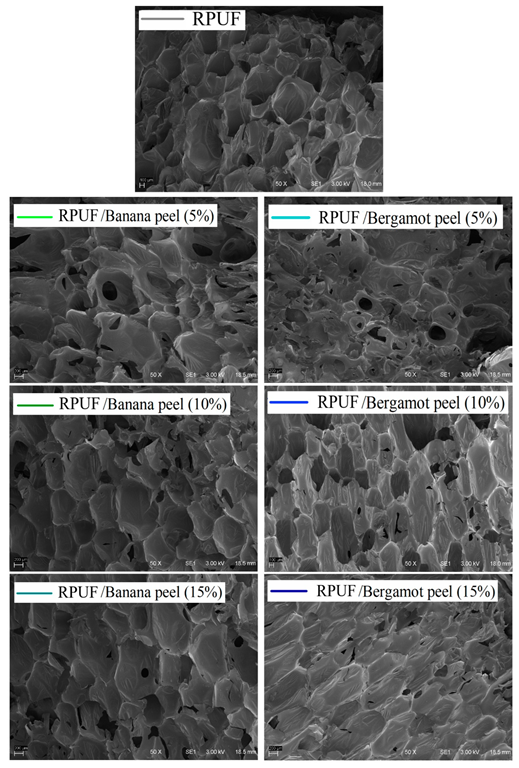

SEM images of the studied RPUF. Where: RPUF is the neat rigid polyurethane foam. Image Credit: Acosta, A.P et al., Polymers

The Study

The authors have focused on the use of two common but underutilized waste products from the oil and juice-pressing industries, banana peel and bergamot peel. It has been noted that research into sustainable rigid polyurethane foam has already investigated the use of cellulose-based fibers, lignin particles, paper and powder residues, and industrial and domestic residues as fillers.

Using vegetable and fruit waste by-products holds the potential to significantly reduce the cost of rigid polyurethane foam manufacture, having marked cost benefits over synthetic fillers. Bananas are the second largest consumed food crop in the world, with in excess of a hundred million tons consumed per year. Aside from direct consumption, bananas are used in jams, alcohol, and other food and drink products.

Bergamot is used in juice and oil production, with one of their main commercial uses being essential oils. Additionally, bergamot peels are used in animal feed, and the peel makes up around 50-60% of the fruit’s total weight. Vast amounts of peel from both banana and bergamot processing are wasted annually every year.

Both fruits were sourced from a supermarket in Brazil and prepared using an oven-drying process. Wet analysis and ash content analysis on the dried peels were performed. The authors investigated the incorporation of peel from both fruits in rigid polyurethane foam in three different proportions, which were five, ten, and fifteen percent.

Once incorporated into the prepared polyurethane biofoam, FT-IR, morphological testing, thermal stability analysis, water uptake analysis, and compressive strength testing were performed to characterize the material samples. Additionally, statistical analyses were implemented.

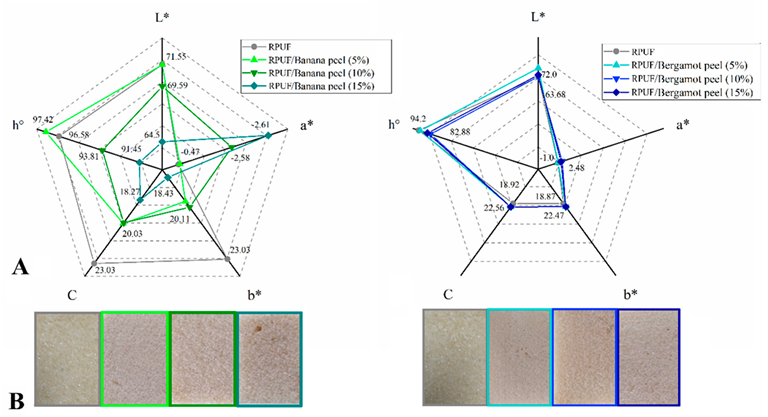

Colorimetric properties (A) and photographs (B) of the studied RPUF with Banana peels (A) and Bergamot peels (B). RPUF is the neat rigid polyurethane foam and filler type, and filler content is the numbers after the bars and between parentheses, respectively. Where: L* is brightness; a* is green-red coordinate; b* is blue-yellow coordinate; C is chroma; h° is hue angle. Image Credit: Acosta, A.P et al., Polymers

Study Findings

FTIR and wet chemical analysis confirmed the filler’s high chemical compatibility with polyurethane, with SEM analysis demonstrating sufficient filler distribution. Bergamot peel outperformed banana peel in terms of compatibility with the polyurethane host. Filler type and content only slightly affected the color, apparent density, hygroscopic, and compressive strength properties of the prepared samples.

Compared to neat rigid polyurethane foam, the biofiller-incorporated samples showed increased thermal stability of 114% and an 80% increase in cell size. A 15% incorporation of bergamot peel as a filler displayed outstanding results, with ellipse-like cell bubbles promoted by nucleating mechanisms. However, low filler/rigid polyurethane foam interface strength and cell edge disruption was observed.

Finally, the authors have stated that future research will be needed to provide more in-depth knowledge of the effect of these biofillers on the polyurethane foam’s dimensional stability and thermal conductivity.

Further Reading

Acosta, A.P et al. (2022) Rigid Polyurethane Biofoams Filled with Chemically Compatible Fruit Peels Polymers 14(21) 4526 [online] mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/21/4526

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.