Reviewed by Emily Henderson, B.Sc.Nov 4 2022

Elisa Riedo, a Professor of Chemical and Biomolecular Engineering, and her colleagues have uncovered a fundamental friction law that is helping to improve the knowledge of how energy is lost during friction and how to create two-dimensional materials that waste as little energy as possible.

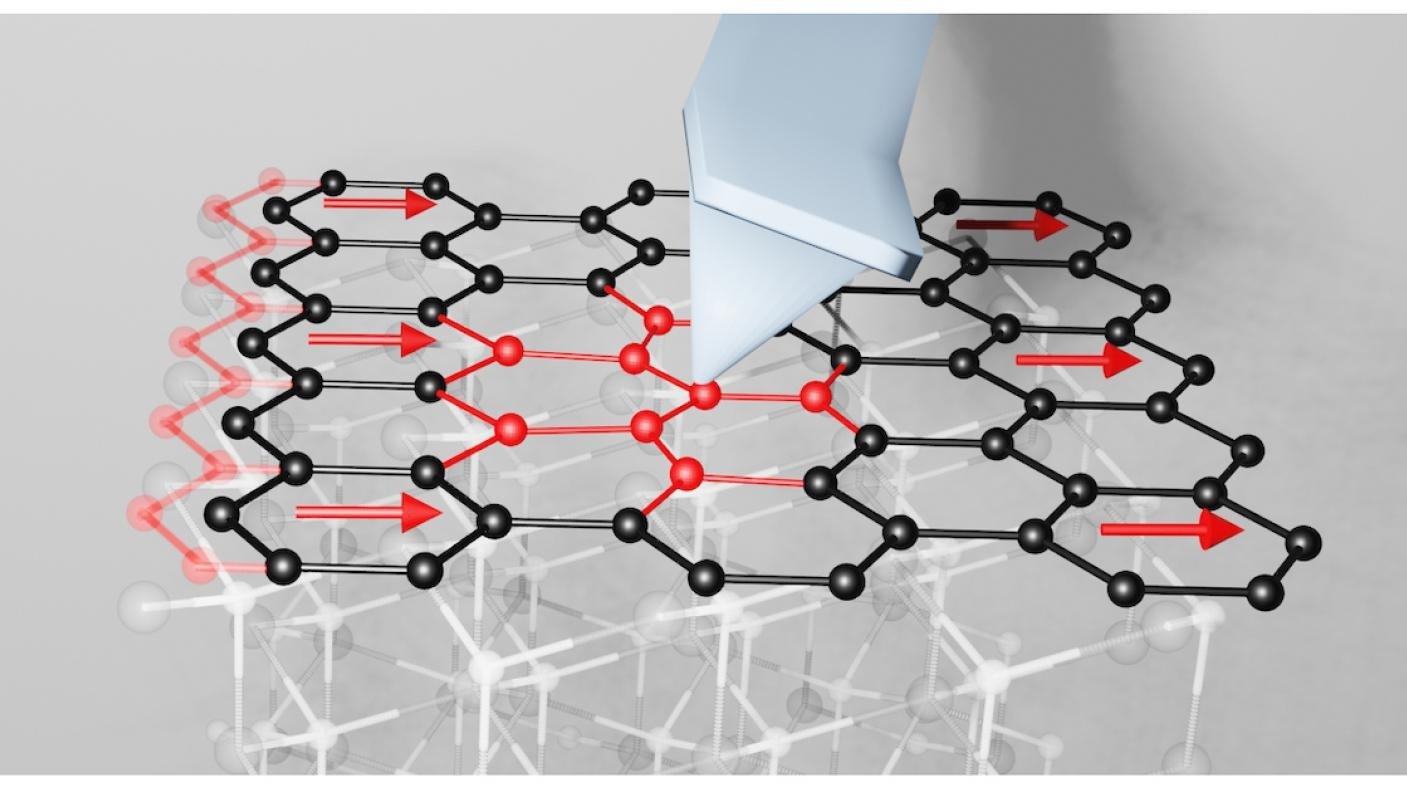

Measuring atomic shear: in this rendering, a nano-scale tip pulls atoms so they slide on top of others. Image Credit: NYU Tandon School of Engineering

Measuring atomic shear: in this rendering, a nano-scale tip pulls atoms so they slide on top of others. Image Credit: NYU Tandon School of Engineering

Friction is a common occurrence that enables dancers to perform intricate routines on diverse floor surfaces and helps drivers to stop their cars by breaking. However, it could also have an unintended consequence that causes energy waste in industrial processes, the transportation industry, and other areas.

According to tribologists, who research the science of interacting surfaces in motion, friction and wear account for around one-fourth of all global energy losses.

The fundamental laws of friction are still unknown, despite the fact that friction is extremely common and important in technology. Only recently have scientists been able to use advancements in nanotechnology to understand, for instance, the microscopic origin of da Vinci’s law, which states that frictional forces are proportional to the applied load.

Riedo and Martin Rejhon, a Postdoctoral Researcher at NYU Tandon, have now developed a novel technique to measure the interfacial shear between two atomic layers and showed that, according to a new law, this amount is inversely related to friction.

Francesco Lavini, a graduate student at NYU Tandon, and colleagues from the International School for Advanced Studies, the International Center for Theoretical Physics in Trieste, Italy, and Prague’s Charles University collaborated on this research, which has the potential to improve manufacturing procedures, produce more ecofriendly vehicles, and improve sustainability throughout society.

The interaction between a single atomic layer of a material and its substrate governs its electronic, mechanical, and chemical properties so gaining insight into that topic is important, on both fundamental and technological levels, in finding ways to reduce the energy loss caused by friction.

Elisa Riedo, Professor, Chemical and Biomolecular Engineering, Tandon School of Engineering, New York University

The interfacial transverse shear modulus of an atomic layer on a substrate, which is difficult to measure, was examined in the study of bulk graphite and epitaxial graphene films produced with various stacking orders and twists.

They discovered that the stacking order and the atomic layer-substrate interaction play a significant role in controlling and predicting sliding friction in supported two-dimensional materials and showed how the modulus—a measure of the material’s capacity to resist shear deformations and remain rigid—is significantly influenced by these factors.

For all the graphite structures they looked at, their investigations revealed a universal reciprocal link between friction force per unit contact area and interfacial shear modulus.

Their 2022 paper, “Relation between interfacial shear and friction force in 2D materials,” was funded by the US Department of Energy Office of Science and the US Army Research Office. It was published online in Nature Nanotechnology.

Riedo stated, “Our results can be generalized to other 2D materials as well. This presents a way to control atomic sliding friction and other interfacial phenomena, and has potential applications in miniaturized moving devices, the transportation industry, and other realms.”

Riedo also oversees the PicoForce Lab at NYU Tandon.

Elisa’s work is a great example of NYU Tandon’s commitment to a more sustainable future and a testament to the research being done at our newly launched Sustainable Engineering Initiative, which focuses on tackling climate change and environmental contamination through a four-pronged approach we are calling AMRAd, for Avoidance, Mitigation, Remediation, and Adaptation.

Jelena Kovačević, Dean, Tandon School of Engineering, New York University

Journal Reference:

Rejhon, M., et al. (2022) Relation between interfacial shear and friction force in 2D materials. Nature Nanotechnology. doi:10.1038/s41565-022-01237-7