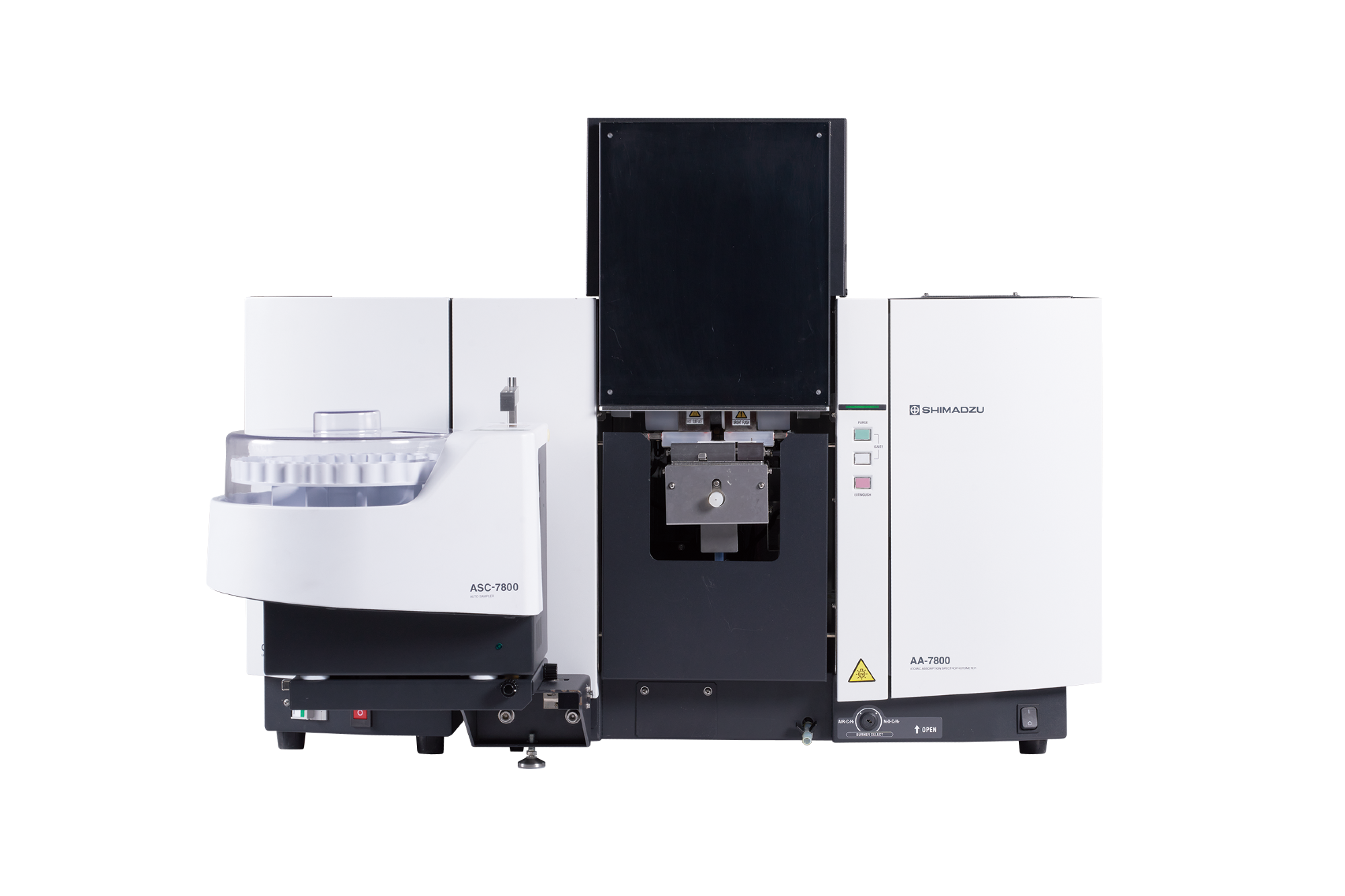

Shimadzu Scientific Instruments (SSI) announces the release of its new AA-7800 Series Atomic Absorption Spectrophotometers. These instruments offer high sensitivity, stability and comprehensive safety elements, provide excellent versatility with a variety of options, and support multi-element analysis. The series also features the industry’s smallest dual atomizer system.

Image credit: Shimadzu SSI

These new spectrophotometers enable safe, high-performance flame analysis. For flame atomic absorption spectrophotometers that use acetylene gas, AA-7800 spectrophotometers are equipped standard with a variety of safety mechanisms, such as a vibration sensor and a gas leak check function. Double-beam optics and many other extra features ensure reliable data acquisition. In addition, users can analyze a variety of samples using the extensive selection of functions and options.

At only 940 mm wide – including furnace power supply unit – the dual atomizer system is the world’s smallest. The smart design enables an upgrade of a flame system to a dual atomizer system, even after installation. Another smart design feature is the lamp housing unit, which enables the installation of eight high-performance hollow cathode lamps in a turret with automatic switching.

The double-beam optical system provides high basic performance because the AA-7800 spectrophotometers are equipped with a three-dimensional optical system that is automatically set to the optical double-beam mode for flame measurements. In addition, the high-speed digital filter and use of optical components with extremely low optical loss levels achieve data stability and high sensitivity.

Because the optimal flame gas flowrate value must be determined when using organic solvents or after changing the burner height, AA-7800 spectrophotometers perform the gas flowrate optimization process automatically. The AA-7800F/AAC model automatically searches for the optimal burner height setting by varying it in 0.5 mm increments.

Clear, easy-to-use WizAArd software enables efficient setting of analytical parameters. A simple layout shows measurement status at a glance, while hardware validation software ensures quick evaluation of instrument performance. Adding an optional connection kit enables compliance with electronic record and electronic signature requirements, such as those specified in FDA 21 CFR Part 11.