Advances in battery technology in recent decades have radically changed the world we live in, powering a vast array of devices in key applications, from smartphones and laptops to medical devices and electric vehicles, as well as being implemented in satellite systems. Batteries are now ubiquitous in our daily lives, with lithium-ion (Li-ion) batteries taking center stage in the battery revolution.

Image Credit: Stanford University

Yet, one of the major concerns with Li-ion batteries is that if their operating temperature exceeds 140 °F (60 °C) or they are structurally compromised because of an internal or external failure, they become a serious fire hazard. The electrolyte that transfers the lithium ions between the electrodes is a flammable material.

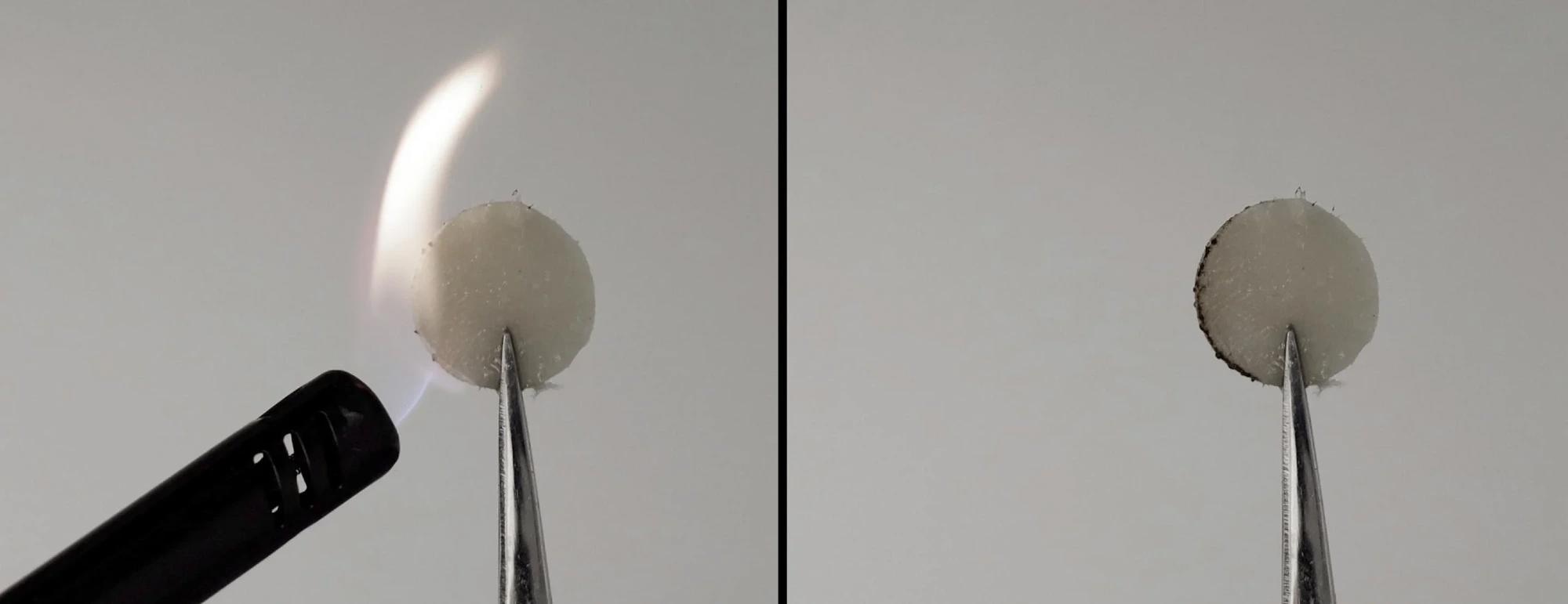

Now, a group of researchers at Stanford University has developed a flameproof polymer-based electrolyte that does not run an increased risk of catching fire when operating at temperatures exceeding 140 °F.

One of the biggest challenges in the battery industry is this safety issue, so there’s a lot of effort going into trying to make a battery electrolyte that is safe.

Rachel Z Huang, Graduate Student, Stanford University

Pushing the Envelope

The study, recently published in the journal Matter, reveals that the secret to their innovative non-flammable electrolyte for use in Li-ion batteries is salt. The Stanford-based researchers, working in collaboration with the Department of Energy’s SLAC National Accelerator Laboratory, demonstrated how batteries using this novel electrolyte could sustain adequate functionality at high temperatures without catching fire.

Due to the fact batteries produce heat during operation, there is no escaping the fact that maintaining good functionality at elevated temperatures is fundamental in battery design. However, if a battery is damaged or compromised in any way, it will start to heat up much faster as molecules evaporate, which heightens the risk of catastrophic failures in both the battery and the devices it powers.

Conventionally, Li-ion batteries use a lithium-based salt dissolved in an organic solvent to help with the transfer of lithium ions between the electrodes, and while flammable, the electrolyte is extremely efficient at moving these lithium ions around. Moreover, previous iterations of polymer-based electrolytes have not matched the performance of existing electrolytes.

Huang proposed that the team should try to push the envelope of polymer-based electrolytes by introducing LiFSI, a lithium salt, to a polymer-based electrolyte developed by Jian-Cheng Lai, co-author and postdoctoral researcher at Stanford University.

Normally, the total weight of a polymer-based electrolyte will be comprised of less than 50% salt. Huang tested this by increasing the salt content so that it accounted for around 63% of the total electrolyte weight.

SAFE-ty First

One of the other standouts of this salty electrolyte is that it also contains flammable molecules, which at first may sound counterintuitive to the project's research aims. Yet, the Solvent-Anchored non-Flammable Electrolyte (dubbed SAFE) demonstrated the ability to operate at elevated temperatures when tested in a lithium-ion battery.

The reason the electrolyte is able to still incorporate flammable molecules is that the increased salt levels prevent the flammable molecules from evaporating, thus mitigating the risk of catching fire. The SAFE batteries were able to function in temperature ranges between 77-212 °F.

With SAFE there’s no need to change any of the manufacturing setup… Of course, if it is ever used for production there are optimizations needed for the electrolyte to fit into the production line, but the work is a lot less than any of the other systems.

Rachel Z Huang, Graduate Student, Stanford University

Making EVs Safer

These developments in Li-ion battery technology could potentially address one of the major concerns automotive manufacturers have when it comes to installing Li-ion batteries in electric vehicles (EVs). Usually, EV battery packs contain more than one Li-ion battery, and the heat transfer between each unit has the potential to overheat other units, increasing the risk of fire.

Cars can then become vulnerable to impact and collision, which can also compromise the structural integrity of the battery packs. To combat these issues, auto manufacturers usually load EVs with extra cooling systems, which adds weight to the system, leading to a decrease in battery efficiency, meaning more charges between cycles.

“This new finding points out a new way of thinking for polymer-based electrolyte design,” said Zhenan Bao, a professor at Stanford University and investigator with the Stanford Institute for Materials and Energy Sciences (SIMES), who advises Huang.

This electrolyte is important for developing future batteries that are both high energy density and safe.

Zhenan Bao, Professor, Stanford University

SAFE batteries could be the batteries of the future in EVs, not only improving safety and allaying any concerns regarding the potential to catch fire but also it would boost battery efficiency meaning EVs could travel further between charges.

All in all, flame-retardant Li-ion batteries have the potential to change the game in terms of battery production moving forward and ensure that crucial devices are that little bit safer.

References and Further Reading

Patrick, C. (2022) Flameproofing lithium-ion batteries with salt, SLAC National Accelerator Laboratory. Available at: https://www6.slac.stanford.edu/news/2022-12-07-flameproofing-lithium-ion-batteries-salt

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.