A method has been developed by an international team of researchers that uses liquid metal to produce an elastic material that is virtually immune to both gases and liquids. The material can be used to package valuable technology that needs to be protected from gases, including flexible batteries.

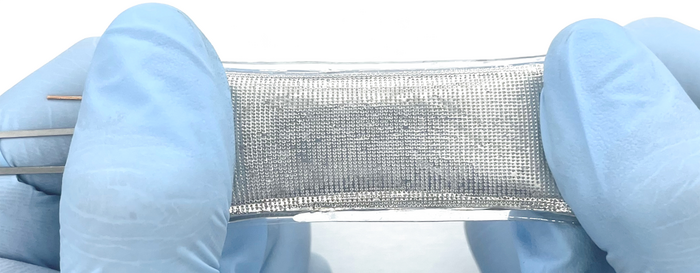

An international team of researchers has developed a technique that uses liquid metal to create an elastic material that is impervious to both gases and liquids. Applications for the material include use as packaging for high-value technologies that require protection from gases, such as flexible batteries. Image Credit: Michael Dickey, NC State University

An international team of researchers has developed a technique that uses liquid metal to create an elastic material that is impervious to both gases and liquids. Applications for the material include use as packaging for high-value technologies that require protection from gases, such as flexible batteries. Image Credit: Michael Dickey, NC State University

This is an important step because there has long been a trade-off between elasticity and being impervious to gases.

Michael Dickey, Co-Corresponding Author and Camille and Henry Dreyfus Professor, Chemical and Biomolecular Engineering, North Carolina State University

Dickey further stated, “Basically, things that were good at keeping gases out tended to be hard and stiff. And things that offered elasticity allowed gases to seep through. We have come up with something that offers the desired elasticity while keeping gases out.”

A gallium-indium eutectic alloy (EGaIn) is used in the new method. Eutectic refers to an alloy with a lower melting point than its component elements. The EGaIn is liquid at room temperature in this instance.

A thin coating of EGaIn was generated by the researchers, who then covered it with an elastic polymer. Glass microbeads were placed on the polymer’s internal surface to prevent the liquid coating of EGaIn from pooling. The result is essentially a liquid metal-lined elastic bag or sheath impermeable to gases and liquids.

By measuring the amount of liquid content evaporation and oxygen leakage from a sealed container composed of the new material, the researchers could determine how effective the material was.

We found that there was no measurable loss of either liquid or oxygen for the new material.

Tao Deng, Study Co-Corresponding Author and Zhi Yuan Chair Professor, Shanghai Jiao Tong University

The expenses involved in producing the new material are also a concern for the researchers.

Deng added, “The liquid metals themselves are fairly expensive. However, we are optimistic that we can optimize the technique—for example, making the EGaIn film thinner—in order to reduce the cost. At the moment, a single package would cost a few dollars, but we did not attempt to optimize for cost so there is a path forward to drive cost down.”

To find out if the material is genuinely a barrier that is even more effective than they have been able to demonstrate thus far, the researchers are presently looking into testing possibilities.

Dickey stated, “Basically, we reached the limit of the testing equipment that we had available. We are also looking for industry partners to explore potential applications for this work. Flexible batteries for use with soft electronics is one obvious application, but other devices that either use liquids or are sensitive to oxygen will benefit from this technology.”

This week, the study will be released in the journal Science. The study’s co-first authors include Man Hou Vong, a Ph.D. candidate at NC State, Qingchen Shen, a former visiting scholar at NC State who is now at Shanghai Jiao Tong University, as well as Modi Jiang, Ruitong Wang, and Kexian Song from Shanghai Jiao Tong University.

Dickey, Deng, Wen Shang of Shanghai Jiao Tong University, and Jun Wang of A123 Systems are the co-corresponding authors of the study.

Febby Krisnadi, a Ph.D. student at NC State; Woojing Jung, a former visiting scholar at NC State; and Ruyu Kan, Feiyu Zheng, Benwei Fu, Peng Tao, Chengyi Song, and Guoming Weng of Shanghai Jiao Tong University, and Bo Peng of A123 systems are the co-authors of the study.

The National Science Foundation awarded grants EEC-1160483 and CMMI-2032415 to support this study. The National Natural Science Foundation of China awarded grants 51873105 and 51973109 to support it.

The Innovation Program of the Shanghai Municipal Education Commission awarded a grant 2019-01-07-00-02-E00069 to find the study. Zhi-Yuan Endowed fund from Shanghai Jiao Tong University and Shanghai Jiao Tong University Overseas Study Grants also provided funding.

Journal Reference:

Shen, Q., et al. (2023) Liquid metal-based soft, hermetic, and wireless-communicable seals for stretchable systems. Science. doi:10.1126/science.ade7341.