Parker Hannifin, the global leader in motion and control technologies, has launched a new comprehensive catalogue detailing its range of Bestobell high-performance cryogenic valves used in applications for the transportation, storage, and processing of ultra-low temperature liquefied gases.

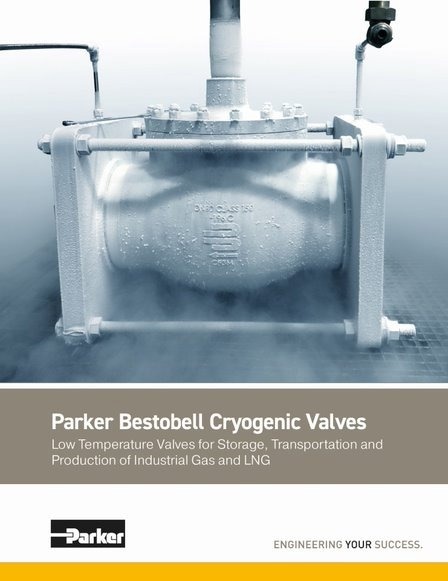

Image Credit: Parker Hannifin.

As a market-leading manufacturer of cryogenic valves, Parker’s 70-page catalogue offers extensive technical information on its products, materials of construction and detailed information on design conformance, certifications and approvals. Parker Bestobell valves are designed and manufactured in accordance with ASME B31.3, BS EN 1626, and BS ISO 21011 and are compliant with Pressure Equipment Directive (EU PED 2016): 2014/68/EU.)

The catalogue also benefits from detailed ordering sections for each valve type with simplified part numbering, allowing users to easily configure the product to the required specification. A complete list of spare parts has been added to the catalogue, also with simplified part numbering for customer ease. All part numbers contained in the new catalogue form part of Parker’s core range and are available to manufacture.

Installation guidance has been provided for each valve type to ensure correct valve orientation. Detailed instructions can be found in the Installation, Operating and Maintenance Instructions (IOMs) for each product series, available to download from Parker’s website.

Parker Bestobell’s range includes cryogenic manual and actuated globe, gate and ball valves, as well as check valves, safety and thermal relief valves, strainers, fill manifolds, and pressure regulators. Each valve has been designed to meet industry requirements to withstand temperature changes, possible expansion or contraction, and avoid deformation of its mounting. To view the full range, download the catalogue here.

About Parker’s Instrumentation Products Division, Europe

The Instrumentation Products Division, Europe provides highly engineered pressure and temperature process control instrumentation and systems. These range from compression tube fittings, cone and thread fittings, needle valves, ball valves, compact stream switching valves to modular process to instrument valve packages. These items are all developed and manufactured to increase our customers’ up-time, maintain safety, and improve production and quality control. Learn more at www.parker.com/ipd.