Time changes everything, especially where the elements are concerned. This puts almost all known structures and objects, man-made and natural, at the destructive mercy of corrosion. With an entire field of engineering dedicated to controlling and preventing corrosion, the amount of time and money that goes into combatting the inevitable is costly.

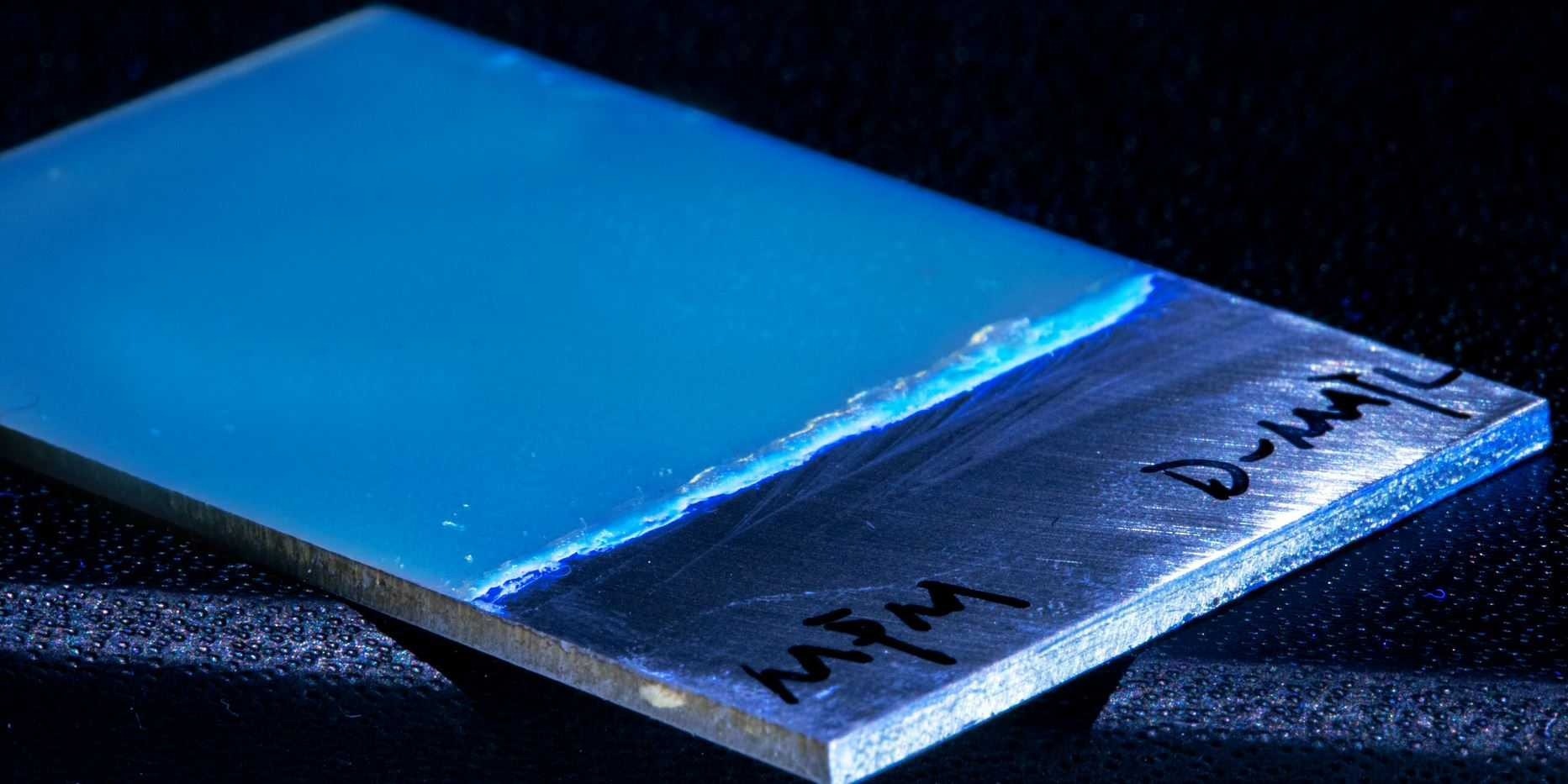

Image Credit: Marco D’Elia / ETH Zurich

It is projected that countries worldwide invest a total of 2.5 trillion US dollars (USD) each year to prevent corrosion, which is about 3.5% of the global gross domestic product (GDP).1 In the US, the cost comes in at an eye-watering 4000 billion USD annually.1

Now, a team of researchers at ETH Zurich has developed an exceptional material that offers protection against the destructive effects of corrosion. The wonder material is PPM, which stands for Poly(phenylene methylene), a florescent polymer with exceptional thermal and hydrophobic properties. The team published their findings in the journal Polymers.

Self-Repairing PPM

This innovative corrosion protection polymer has multifaceted benefits. Firstly, PPM can be combined with paint and heated for surface spraying. Once applied, PPM solidifies, revealing any cracks and holes in the protective layer in areas that fail to fluoresce.

However, the real stand-out aspects of this anti-corrosion material are its ability to self-repair and, at the end of a product’s life, the polymer can be removed entirely and recycled with only minimal material loss.

Astonishingly, the potential of all of these remarkable features in anti-corrosion applications was brought about by sheer chance.

Markus Niederberger, the paper's lead author, was working on nanoparticle production for solvents with a group of researchers in his laboratory at the time of the discovery. The solvents they were working with solidified when exposed to certain conditions.

That was unintentional and unwanted… We didn’t know what to do with it at first either.

Markus Niederberger, ETH Zurich

Previously, anti-corrosion coatings developed with PPM were prone to cracking, limiting their application in real-world scenarios. Yet, this chance discovery helped researchers realize that with the addition of plasticizers, a blended PPM mix could be an effective material to combat corrosion in several applications.

Durable Innovation

When testing the PPM blend, the team found that the coating effectively protected metals, particularly aluminum, against corrosion. Moreover, the protective PPM-based coating can be applied in thin layers, up to ten times thinner than traditional protective agents, including epoxy resin, while demonstrating excellent durability.

This durability is further improved upon, given the self-repairing nature of the innovative PPM-based material.

Self-repair mechanisms are in great demand, but they’re very difficult to attain, and good solutions are still rare.

Walter Caseri, ETH’s Laboratory for Multifunctional Materials

To achieve these self-repairing capabilities, materials typically require the addition of chemical additives, which with prolonged application use, can migrate through the polymer out into the environment.

However, as Caseri explains, this material does not require any additives, making it much more environmentally compatible, which is boosted by the fact the material can be recycled or reused, as previously mentioned.

Yet, caution should always be taken when using synthetic, man-made materials as they can still pose some environmental risk. Therefore, the team will work on improving the material to maximize its application potential further.

The team has now filed for a patent for their discovery while seeking industry partners to take the wonder material to the next level and scaling up for manufacture. They believe their material would be a viable alternative to the thermosetting resins commonly used in anti-corrosion settings today.

References and Further Reading

- Rüegg, P. (2023) New Corrosion Protection that repairs itself, ETH Zurich. Available at: https://ethz.ch/en/news-and-events/eth-news/news/2023/02/new-corrosion-protection-that-repairs-itself.html

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.