Superconductors are used for a wide range of industrial applications, such as electric motors, flywheel energy systems, and magnetic levitation. Researchers from the Shibaura Institute of Technology, Japan, now propose performance-optimized superconductors using various liquid sources. The synthesized ternary bulk materials comprising of heavy elements mixed with rare earth elements as a liquid source demonstrate improved superconducting performance for revolutionizing real-life applications.

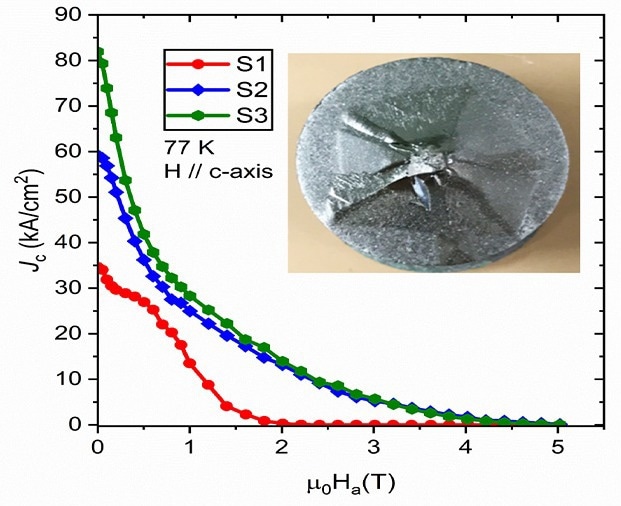

Title: Field dependence of the critical current density (JC) measured at 77 K. Caption: New superconductors set to revolutionize domestic and industrial applications. Image Credit: Muralidhar Miryala from SIT, Japan

Title: Field dependence of the critical current density (JC) measured at 77 K. Caption: New superconductors set to revolutionize domestic and industrial applications. Image Credit: Muralidhar Miryala from SIT, Japan

Superconductors are increasingly finding applications in several areas, such as medical imaging techniques, drug delivery systems, energy storage systems, levitation processes, and water purification methods. This can be attributed to their awe-inspiring ability of zero resistance, which ensures the passage of a high amount of current through them, making them suitable for revolutionizing power transmission and transportation.

Magnetic superconductors are commonly synthesized by the “top-seeded melt growth technique” (TSMG). This process, however, has certain drawbacks, such as huge loss of liquid source material while production. This results in changes to the material composition, cracks in the matrix of the formed material, mechanical shortcomings, and even low thermal conductivity. As an alternative, the infiltration growth process, that involves stacking secondary phase pellets on a liquid phase pellet, has been developed for better efficiency in production and applications. Several compositions of a liquid phase have been used for fabricating such bulk superconductors. However, large, single-grain, bulk rare earth (RE) materials, such as RE-123, are still difficult to synthesize using the infiltration growth process.

Now, however, researchers from Japan focus on the use of heavy elements such as gadolinium (Gd), yttrium (Y) and erbium (Er), to synthesize single-grain bulk and ternary superconductors, with liquid stock composition and infiltration growth technique. They also closely analyze the microstructure and properties (superconducting and electromagnetic) of the formed superconducting material (Gd, Y, Er)-123. Their findings reveal huge performance improvement of these ternary bulks, compared to the currently available materials in the market. The study was led by Professor Miryala Muralidhar of the Shibaura Institute of Technology and was made available online in the Journal of Alloys and Compounds.

First, the researchers evaluated the performance of multiple liquid source starting materials to grow a (Gd, Y, Er)-123 single grain bulk. After ascertaining that Er123 and Ba3Cu5O8 in a 1:1 ratio was the best liquid phase stock material, they proceeded with adding other primary element components, using their respective oxide powders as the starting material.

On evaluating the current flow at critical temperatures, the resulting superconductor was found to allow the flow of highest current density through it, which was 81.09% higher than the previously available materials in this category. Microstructural analysis with scanning electron microscopy revealed a significant reduction in the secondary phase particle size, with a mean particle reduction of 43.13%, compared to the conventional Ba3Cu5O8.

Discussing these results, Prof. Miryala says, “The results are nothing short of impressive. The fact that we were able to fabricate these bulk superconductors in the air, using a cost-effective method, makes this approach highly attractive for large-scale industrial production.”

Moreover, Er123+ Ba3Cu5O8 also yielded the highest critical current density (Jc) of 81.91 kA/cm2 in self-field and 28.29 kA/cm2 at 1 T for (Gd, Y, Er)-123 ternary system liquid source. The greatly enhanced current density in the newly synthesized material is the most remarkable aspect of this research and has huge potential for applications of magnetic superconductors. “These improvements have the potential to revolutionize real-life applications like magnetic levitation, superconducting bearings, electric motors, magnetic drug delivery (MDD) and flywheel energy systems,” says Prof. Miryala.

With such exceptional properties, superconducting materials such as these can greatly enhance and influence power transmission and transportation systems in the near future. They can also transform multiple industries and become instrumental in combatting climate change, while supporting the Sustainable Development Goals (SDGs) of the United Nations.

In summary, this new approach to synthesizing bulk superconductors has clearly opened the door to mass production of high-performing superconductors and is being deemed as an exciting breakthrough for a wide range of applications.