From cosmetics to medicine to degradable materials, lactic acid (LA) is an essential chemical intermediate for a multitude of products. It is also the building block for biodegradable polylactic acid (PLA), which is a vital component in compostable, recycled plastics.

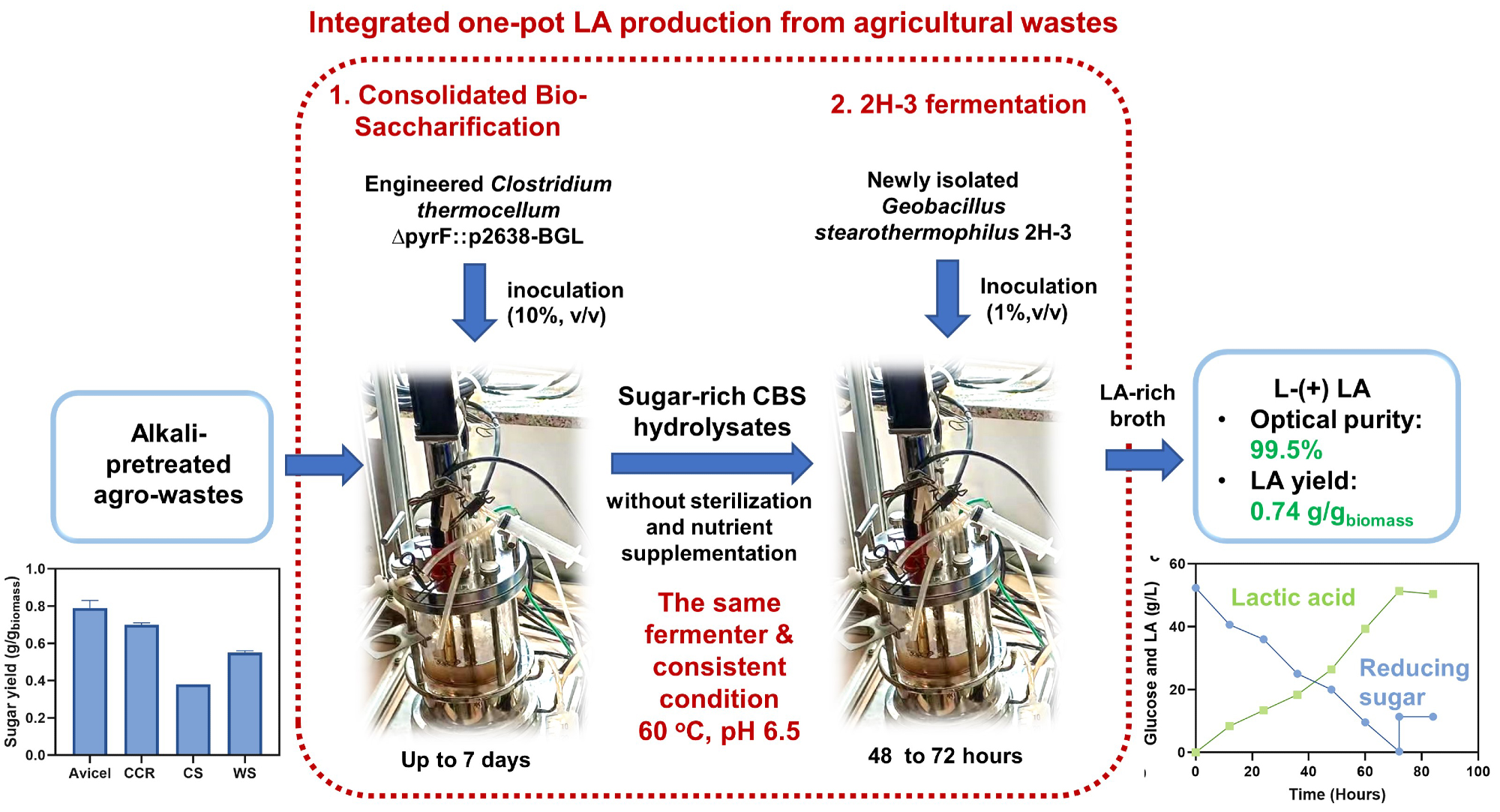

Schematic representation of the integrated LA production process from agro-wastes. Image Credit: LIU Yajun

Schematic representation of the integrated LA production process from agro-wastes. Image Credit: LIU Yajun

With surging demand for lactic acid and PLA in general, finding a non-food carbon source for the LA synthesis process is a huge step in the direction of developing and implementing more sustainable practices.

Scientists from the Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) of the Chinese Academy of Sciences and their co-workers are streamlining a method to use the plentiful agro-waste products in non-food feedstocks to obtain LA from lignocellulose, which is a complicated structural network seen in the cell wall of plants. With consolidated bio-saccharification (CBS), they could take the raw material of lignocellulose and achieve LA via a fermentation process.

The findings were published in Journal of Environmental Management on June 6th, 2023.

Remarkably, the findings helped explain a successful lactic acid producer that the scientists may not have been aware of: Geobacillus stearothermophilus. Upon noticing the contamination in the CBS system, it was found that G. stearothermophilus was a major LA manufacturer and could grow using different sources of sugar as the carbon source. This effectual LA producer, integrated with the comprehensive “one-pot” approach of CBS, can effortlessly produce striking outcomes from a resource and cost-minimizing standpoint.

Our results emphasize the possibility of industrial-scale production of LA from lignocellulosic feedstocks, as the integration method can reduce the need for intermediate sterilization, nutrient supplementation, or adjustment of fermentation conditions.

Yajun Liu, Study First Author, Qingdao Institute of Bioenergy and Bioprocess Technology

The process of breaking down the lignocellulosic biomass into something that has usable sugars for fermentation is the greatest hang-up so far in employing agro-wastes to generate valuable end products. With the use of G. stearothermophilus in the CBS reaction as the catalyst for sugar production, scientists found it to be a very strong producer of high-quality lactic acid that could employ several carbon sources for saccharification or the production of simple sugars from a more complex sugar.

The capacity to produce optically pure, high-yield, and high-quality lactic acid using non-food stocks can have positive consequences for the world’s food supply because food cultivated for consumption is also not being utilized to produce lactic acid.

The CBS process is not limited to producing only lactic acid. It is noteworthy that lactic acid production may be the beginning; other downstream fermentation products might be able to make more use of the abundance of lignocellulose from different agricultural waste products. More products can be produced using a more cost-reducing approach by changing the species and chemicals used in the CBS process.

The CBS technology has been demonstrated to be compatible with various downstream microalgae, yeast, and bacterial fermentation to produce high-value-added chemicals, such as pullulan, with high yield and titer. We hope to see the cycle time reduced and the ability to effectively scale up fermentation.

Qiu Cui, Study Corresponding Author, Qingdao Institute of Bioenergy and Bioprocess Technology

Journal Reference:

Liu, Y. J., et al. (2023) Integrated lactic acid production from lignocellulosic agricultural wastes under thermal conditions. Journal of Environmental Science. https://english.cas.cn/newsroom/research_news/chem/202306/t20230615_331967.shtml.