NSK S1 is the first bioplastic retention piece for ball screws to appear on the global market. Made from 100% renewable biological resources (mainly plants), the use of bioplastic for the new retaining piece reduces carbon footprint by 90% over its lifecycle in comparison with using conventional materials. The development therefore represents an environmentally sustainable choice for any European manufacturer looking to reduce CO2 emissions and meet increasingly stringent regulations.

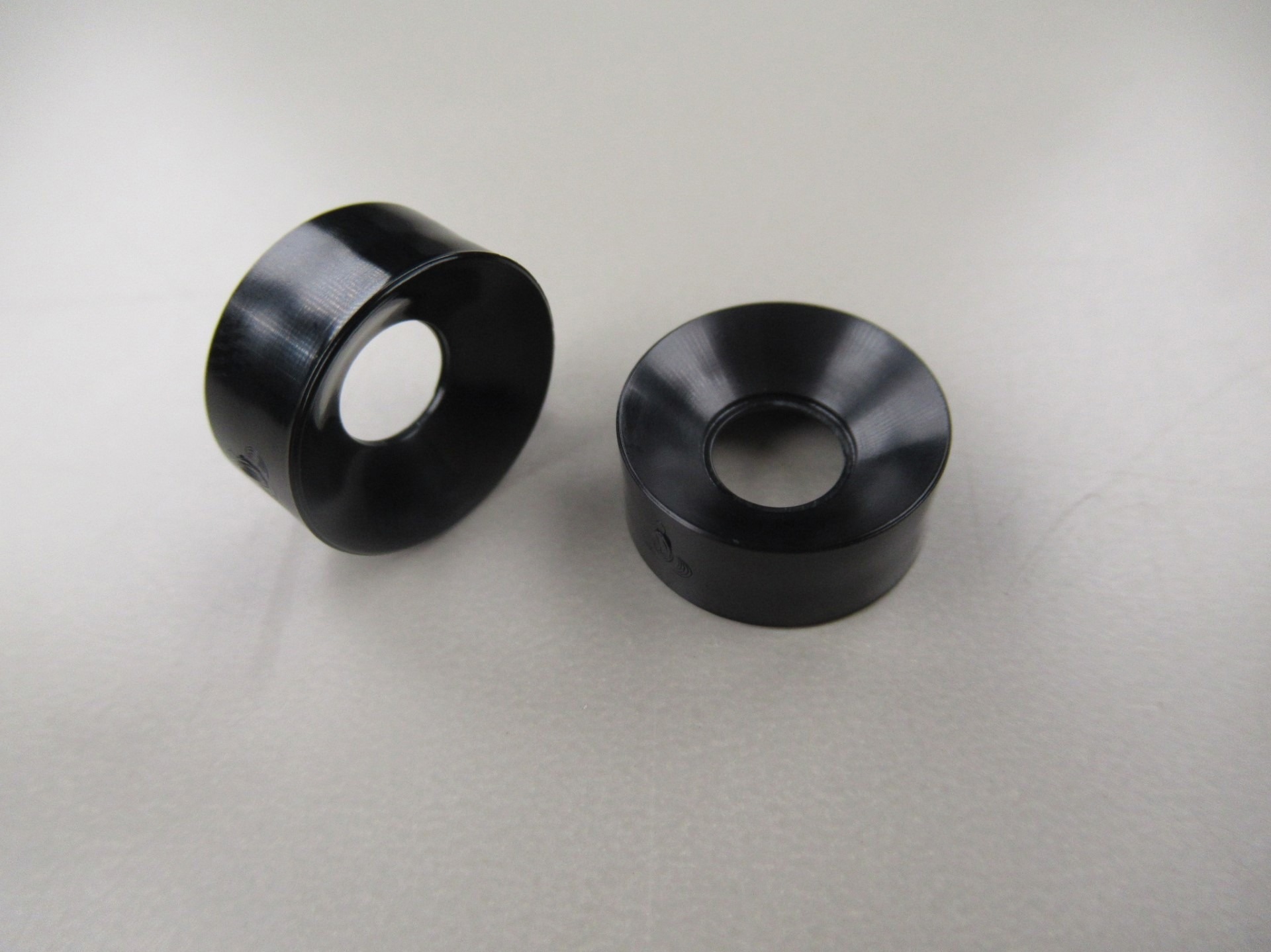

NSK S1 bioplastic retaining piece for ball screws. Image Credit: NSK Europe Ltd

NSK S1 bioplastic retaining piece for ball screws. Image Credit: NSK Europe Ltd

To emphasise the growing need for sustainable solutions, the European Commission released its Net Zero Industry Act in March 2023. A key part of the European Green Deal Industrial Plan, the Act proposes a framework of regulatory measures for strengthening Europe’s net-zero product manufacturing ecosystem. Many countries are now looking to up their game on carbon-neutral initiatives, meaning that low-carbon and environmental measures are increasingly required in a wide variety of industrial machinery.

NSK is committed to realising a carbon-neutral society. As part of this ethos, the company is increasing its use of bioplastics, which are more effective in reducing carbon emissions than conventional fossil fuel-based plastics. Ball screws are a key focus area due to their popularity in all kinds of industrial machines and systems.

Ball screws are highly efficient at transmitting force and converting motion (from rotational to linear), delivering significant energy savings. In recent years, injection moulding machines and servo presses are among many machine types switching from hydraulic to electric drive systems using servomotors and ball screws as a means of reducing power consumption. Considering such industry trends, the demand for ball screws is set for ongoing growth, particularly if sustainable solutions are available.

NSK’s development of its S1 bioplastic retaining piece for ball screws (50 to 200 mm diameter) makes a further contribution to achieving carbon neutrality. Drawing on its expertise in materials technology, NSK selected and validated DSM's EcoPaXX® bioplastic (a plant-derived high-performance polyamide) as the retention piece material. As a point of note, retaining pieces sit between the balls to prevent them from colliding with each other and causing damage.

To optimise and expedite the development process, NSK deployed its digital twin technology. This advanced process enabled the creation of a bioplastic retaining piece with the same performance as a conventional product in a short period of time through the simulation of key parameters such as dimensions, shape, deformation and strength. In short, customers can now leverage the benefit of far lower CO2 emissions while enjoying the same excellent performance levels associated with NSK ball screws.