Henniker Plasma, a leading manufacturer of plasma surface treatment equipment, presents the latest and most reliable solutions for enhancing adhesion performance in the automotive sector.

Plasma pre-treatment is a crucial step for improving the quality and durability of automotive assemblies and components. It enhances the adhesion and compatibility of different materials that are used for encapsulation, printing, or painting processes. By applying plasma to the surface of low-energy materials, it removes contaminants and creates functional groups that increase the surface energy and reactivity. This results in a stronger and more uniform bond between the materials, reducing the risk of failure and defects.

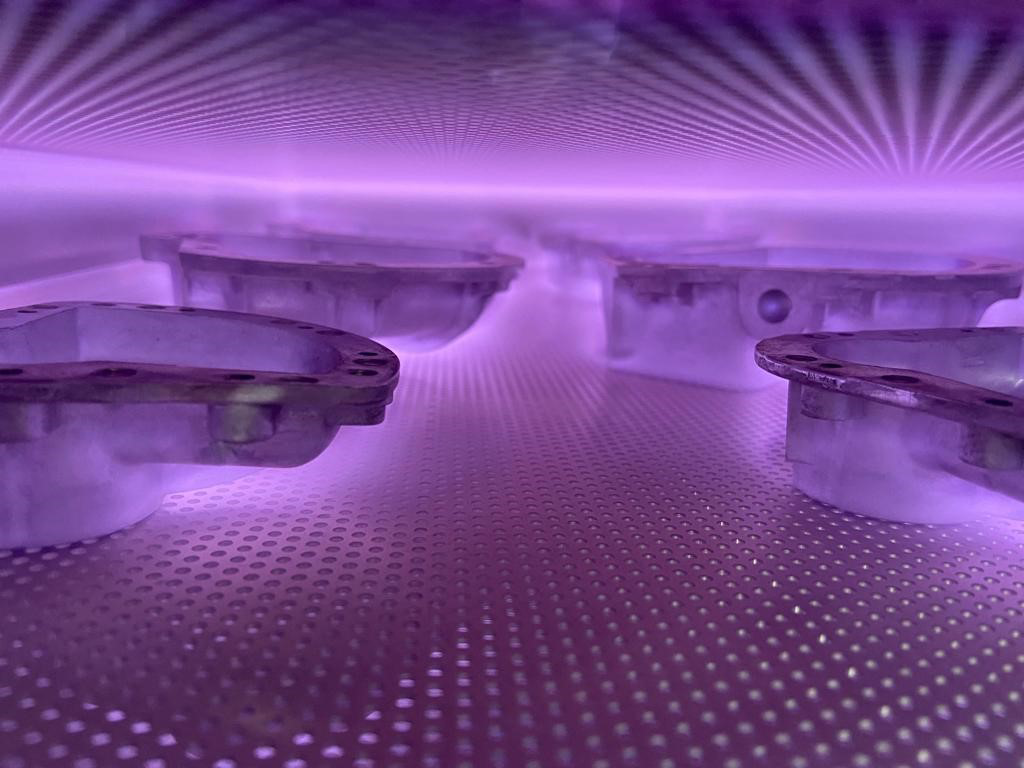

Batch plasma treatment of automotive parts.

Batch plasma treatment of automotive parts.

In the automotive industry, the utilization of advanced treatments like atmospheric and vacuum plasma holds immense potential in significantly improving the adhesion properties of bond lines and electrical connection posts of components prior to their assembly with other parts.

Read our full Press Release here for more information on reducing adhesion failures in the automotive industry: Click here to download the full Press Release