Swedish premium fastener manufacturer BUMAX has been selected to provide fasteners to be used in machines for ultrasonic metal welding. The client is Schunk Sonosystems, a global leading specialist in the field of ultrasonic metal welding.

Image Credit: BUMAX

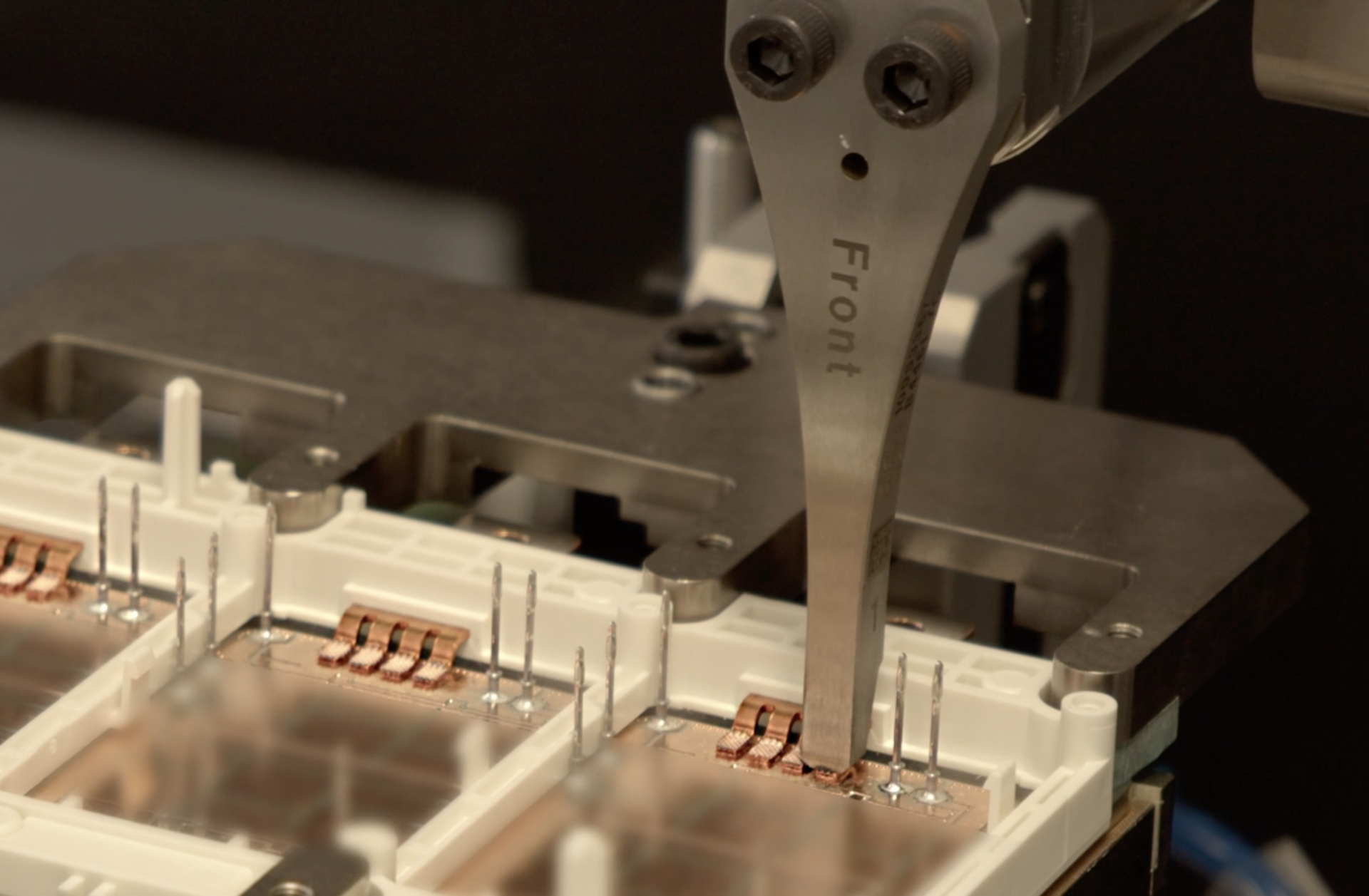

German specialist machine maker Schunk Sonosystems has decided to use BUMAX DX 129 screws for all its ultrasonic welding flexure sonotrode products to further improve quality and reliability. The machines are mainly used in the automobile industry.

"Standard steel bolts simply cannot cope with the extreme pulling and bending forces of ultrasonic vibration, so we had to find a bolt that does,” said Stefan Mueller, Head of R&D at Schunk Sonosystems. “Of all the screws we tested, only BUMAX met all our needs. Not only are BUMAX consistent in how they perform and do not break, they last the lifetime of the sonotrode without problem, are not creating abrasion dust on the screw head and do not require rust protection.”

Extreme Levels of Vibration

Schunk Sonosystems is a global leader in developing and building machines for ultrasonic metal welding – such as their industry-leading flexure sonotrode. Their machines include a sonotrode or welding tip that transfers vibrational energy to the workpiece. Up to two high-strength bolts are required to fix the sonotrode, which is subject to extreme levels of vibration due to the very high frequency used in ultrasonic welding.

Ultrasonic welding is a solid-state welding process that uses ultrasonic vibrations to weld pieces of metal together. The metals are welded together by heat generated by friction when applying high-frequency ultrasonic vibrational energy.

The BUMAX DX 129 (Duplex stainless steel) offers very high tensile strengths of min. 1,200 MPa and excellent fatigue resistance properties. It deals successfully with the with extreme forces during the ultrasonic welding process, such as 20,000 vibrations per second.

Excellent Fatigue Strength

The high fatigue strength that BUMAX screws offer is crucial to their ability to withstand a high number of cycles without fracture. All BUMAX bolts are made with the highest quality European steel, and its advanced manufacturing processes result in the further enhancement of the material’s fatigue resistance properties.

Fatigue fracture often begins with a stress concentration such as inclusions, slags or surface defects. The high-quality raw materials BUMAX uses, together with the best metallurgical processes and good surface properties, guarantee excellent fatigue strength. BUMAX also uses rolled threads rather than cut threads, which further increases fatigue resistance.