High energy density to power devices and stability to be recharged thousands of times safely and reliably are two qualities that make a good battery. For the past three decades, lithium-ion batteries have dominated the market, showcasing their performance in electric vehicles, smartphones, and laptops.

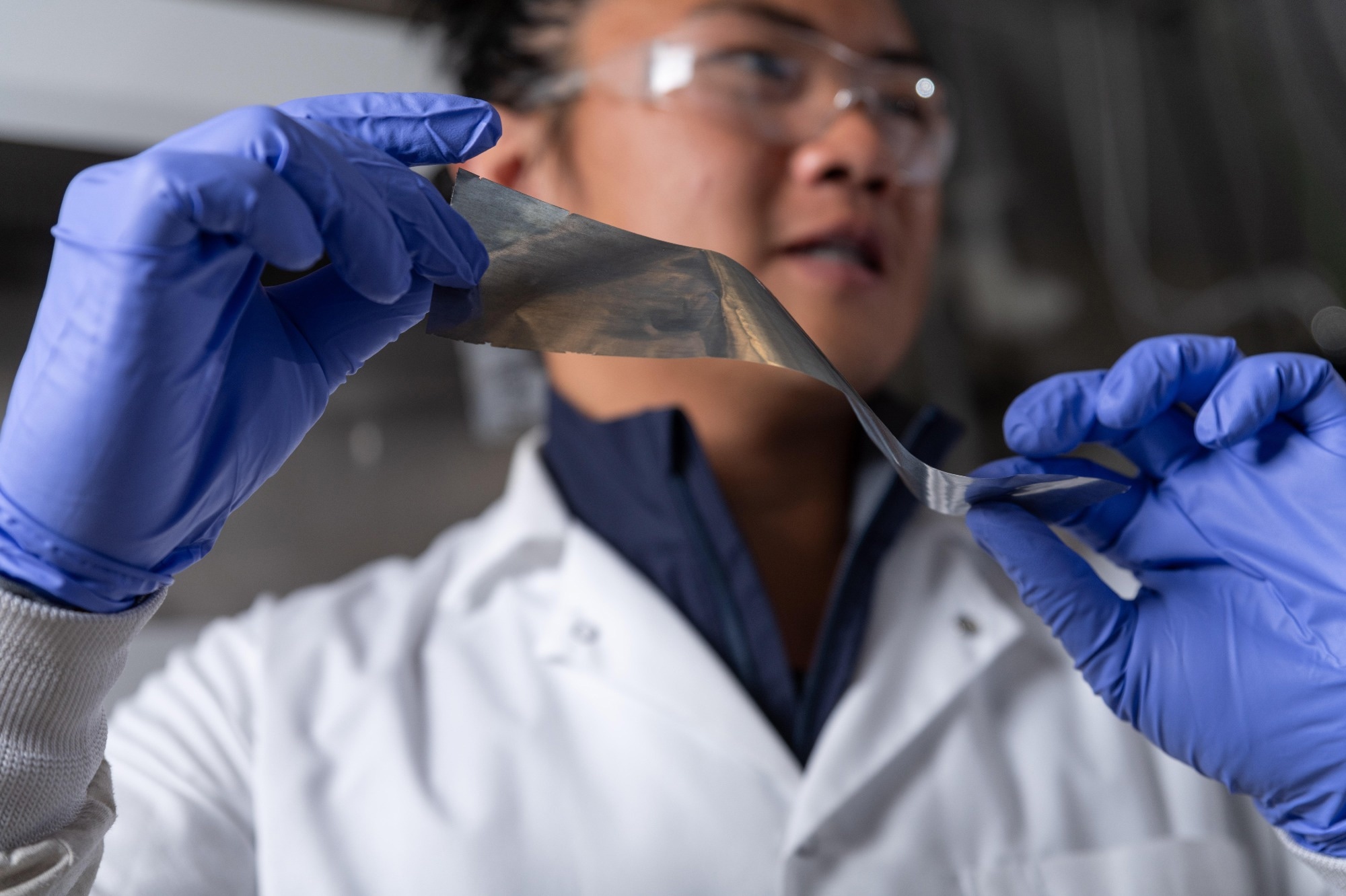

Graduate student researcher Yuhgene Liu holds an aluminum material for solid-state batteries. Image Credit: Georgia Institute of Technology

Graduate student researcher Yuhgene Liu holds an aluminum material for solid-state batteries. Image Credit: Georgia Institute of Technology

However, battery researchers have started to test the limits of lithium-ion batteries. As next-generation long-range vehicles and electric aircraft enter the market, the search for safer, less expensive, and more powerful battery systems that outpace lithium-ion is intensifying.

The Georgia Institute of Technology’s team of researchers, guided by Matthew McDowell, Associate Professor in the George W. Woodruff School of Mechanical Engineering and the School of Materials Science and Engineering, is using aluminum foil to produce batteries with higher energy density and greater stability.

The group’s new battery system could allow electric vehicles to run longer on a single charge while being less expensive to manufacture—all while having a positive environmental impact. The study was published in the journal Nature Communications.

We are always looking for batteries with higher energy density, which would enable electric vehicles to drive for longer distances on a charge. It’s interesting that we can use aluminum as a battery material, because it’s cost-effective, highly recyclable, and easy to work with.

Matthew McDowell, Associate Professor, George W. Woodruff School of Mechanical Engineering, Georgia Institute of Technology

The concept of making batteries out of aluminum is not new. In the 1970s, researchers explored its potential, but it did not work well.

Aluminum fractures and fails after a few charge-discharge cycles in a conventional lithium-ion battery due to expansion and contraction as lithium moves in and out of the material. Aluminum was determined not to be a viable battery material by developers, and the concept was largely abandoned.

Solid-state batteries have now entered the arena. While lithium-ion batteries comprise a flammable liquid that can cause fires, solid-state batteries contain a non-flammable solid material that is likely safer. Solid-state batteries allow for the incorporation of new high-performance active materials.

As part of the Novelis Innovation Hub at Georgia Tech, the Georgia Tech team collaborated with Novelis, a leading aluminum manufacturer and the world’s largest aluminum recycler.

The research team knew that using aluminum as a material in the battery’s anode—the negatively charged side of the battery that stores lithium to create energy—would have energy, cost, and manufacturing benefits, but pure aluminum foils failed quickly when tested in batteries.

The group opted to attempt something new. Instead of using pure aluminum in the foils, they mixed in small amounts of other materials to create foils with unique “microstructures,” or material arrangements. Over 100 different materials were tested to see how they would perform in batteries.

We needed to incorporate a material that would address aluminum’s fundamental issues as a battery anode. Our new aluminum foil anode demonstrated markedly improved performance and stability when implemented in solid-state batteries, as opposed to conventional lithium-ion batteries.

Yuhgene Liu, Study First Author and Ph.D. Student, Georgia Institute of Technology

The research team found that the aluminum anode could store more energy and lithium than other types of anode materials. In the end, they produced batteries with a high energy density that might outperform lithium-ion batteries.

One of the benefits of our aluminum anode that we're excited about is that it enables performance improvements, but it also can be very cost-effective. On top of that, when using a foil directly as a battery component, we actually remove a lot of the manufacturing steps that would normally be required to produce a battery material.

Matthew McDowell, Associate Professor, George W. Woodruff School of Mechanical Engineering, Georgia Institute of Technology

Several companies are working on short-range electric aircraft, but batteries are the limiting factor. Batteries today do not have enough energy to power aircraft over distances of more than 150 miles. New battery chemistries are required, and the McDowell team’s aluminum anode batteries have the potential to pave the way for more powerful battery technologies.

Liu adds, “The initial success of these aluminum foil anodes presents a new direction for discovering other potential battery materials. This hopefully opens pathways for reimagining a more energy-optimized and cost-effective battery cell architecture.”

To better understand how size affects the behavior of aluminum, the team is currently scaling up the size of the batteries. In an effort to develop extremely affordable foils for battery systems, the group is also actively investigating other materials and microstructures.

McDowell concludes, “This is a story about a material that was known about for a long time, but was largely abandoned early on in battery development. But with new knowledge, combined with a new technology—the solid-state battery—we've figured out how we can rejuvenate the idea and achieve really promising performance.”

Journal Reference:

Liu, Y., et al. (2023). Aluminum foil negative electrodes with multiphase microstructure for all-solid-state Li-ion batteries. Nature Communications. doi.org/10.1038/s41467-023-39685-x.