For a range of medical products, Rutgers scientists have developed an extremely precise approach for producing coatings of biologically active materials. This kind of technique could result in a new era of transdermal medication, which includes shot-free vaccinations, the scientists stated.

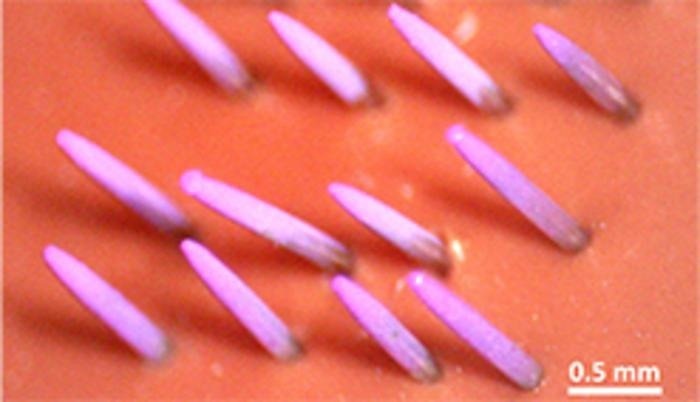

Dyed DNA vaccine coated on a microneedle array by efficient electrospray deposition. Image Credit: Sarah H. Park/Rutgers School of Engineering

Dyed DNA vaccine coated on a microneedle array by efficient electrospray deposition. Image Credit: Sarah H. Park/Rutgers School of Engineering

Detailed in the study, which was published in Nature Communications, the scientists explained a new method of electrospray deposition, which is an industrial spray-coating process. Significantly, Rutgers researchers built a way to better control the target region inside a spray zone along with the electrical properties of microscopic particles that are being deposited. The greater command of those two properties implies that more of the spray is possible to hit its microscopic target.

Manufacturers apply a high voltage to a flowing liquid, such as a biopharmaceutical, in electrospray deposition, transforming it into fine particles. All droplets evaporate as they move to a target area, depositing a solid precipitate from the original solution.

While many people think of electrospray deposition as an efficient method, applying it normally does not work for targets that are smaller than the spray, such as the microneedle arrays in transdermal patches. Present methods only achieve about 40 percent efficiency. However, through advanced engineering techniques we’ve developed, we can achieve efficiencies statistically indistinguishable from 100 percent.

Jonathan Singer, Study Author and Associate Professor, Department of Mechanical and Aerospace Engineering, Rutgers School of Engineering

For a range of medical applications, coatings are increasingly crucial. They are employed on medical devices inserted into the body, like defibrillators, stents, and pacemakers. Also, they are starting to be used more often in new products using biologicals, like transdermal patches.

Advanced biological or “bioactive” materials—like vaccines and drugs—can be expensive to create, specifically if any material is wasted, highly limiting whether a patient can get treatment.

We were looking to evaluate if electrospray deposition, which is a well-established method for analytical chemistry, could be made into an efficient approach to create biomedically active coatings.

Jonathan Singer, Study Author and Associate Professor, Department of Mechanical and Aerospace Engineering, Rutgers School of Engineering

Greater efficiencies could be fundamental in making electrospray deposition more appealing for the production of medical devices with the use of bioactive materials, scientists stated.

Being able to deposit with 100 percent efficiency means none of the material would be wasted, allowing devices or vaccines to be coated in this way. We anticipate that future work will expand the range of compatible materials and the material delivery rate of this high‐efficiency approach.

Sarah Park, Paper First Author and Doctoral Student, Department of Materials Science and Engineering, Rutgers University

Besides, contrary to other coating methods employed in manufacturing, like inkjet printing and dip coating, the new electrospray deposition methodology is defined as “far field,” implying that it does not require extremely precise positioning of the spray source, the scientists stated. Consequently, the equipment required to employ the technique for mass production would be cheaper and easier to develop.

Other Rutgers scientists in the study are professors Jerry Shan and Hao Lin, former doctoral students Lin Lei (currently at Chongqing Jiaotong University) and Emran Lallow (now at GeneOne Life Science, Inc.), and former undergraduate student Darrel D’Souza, all of the Department of Mechanical and Aerospace Engineering; and professors David Shreiber and Jeffrey Zahn, doctoral student Maria Atzampou, and former doctoral student Emily DiMartini, all of the Department of Biomedical Engineering. This work was funded by GeneOne Life Science, Inc.

Journal Reference:

Park, S. H., et al. (2023) Efficient electrospray deposition of surfaces smaller than the spray plume. Nature Communications. doi.org/10.1038/s41467-023-40638-7