Technology is about to undergo a revolution that will alter how devices are utilized. A group of brilliant scientists from the Institute for Basic Science (IBS) in South Korea, led by the esteemed Professor Young Hee Lee, have made an innovative finding that could significantly enhance the production of field-effect transistors (FET).

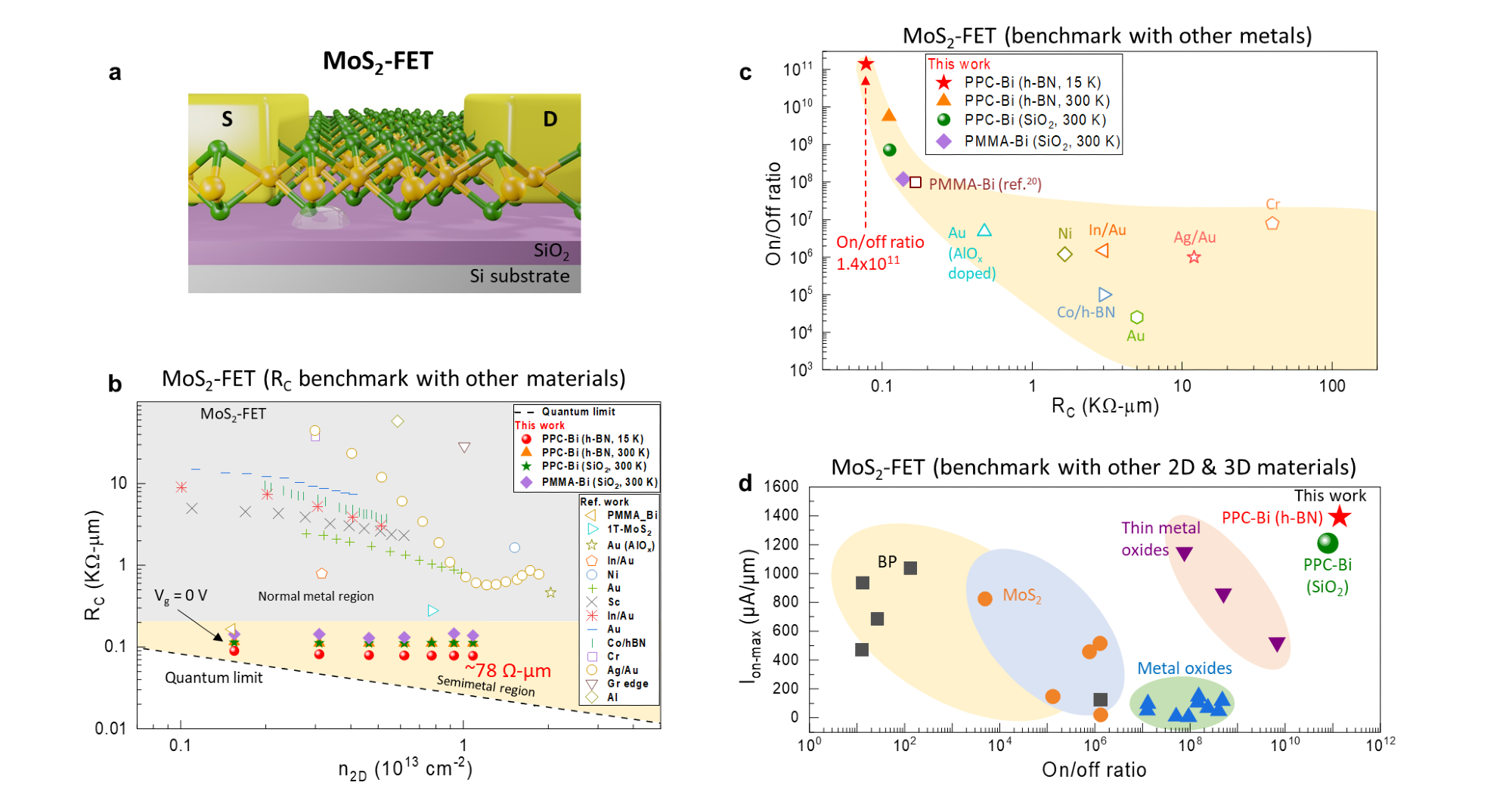

Benchmark of ultra-clean large-area monolayer MoS2-FET. (a) MoS2 FET device schematic. (b) Benchmark of RC vs. n2D in MoS2 FET using different metal contacts for various semiconductor technologies. (c) Benchmark of on/off ratio vs. RC in MoS2 FET compared to different metal contacts used in semiconductor technologies. (d) Benchmark of the maximum on-current (Ion-max) vs. on/off ratio of the MoS2 FET for PPC-Bi contact compared to reports described in the literature. Image Credit: Institute for Basic Science

Benchmark of ultra-clean large-area monolayer MoS2-FET. (a) MoS2 FET device schematic. (b) Benchmark of RC vs. n2D in MoS2 FET using different metal contacts for various semiconductor technologies. (c) Benchmark of on/off ratio vs. RC in MoS2 FET compared to different metal contacts used in semiconductor technologies. (d) Benchmark of the maximum on-current (Ion-max) vs. on/off ratio of the MoS2 FET for PPC-Bi contact compared to reports described in the literature. Image Credit: Institute for Basic Science

A high-performance field-effect transistor (FET) is a fundamental component of the next semiconductor technologies that are not silicon-based. When a device is downsized past sub-3-nm scales, the FET performances of current 3-dimensional silicon technology degrade.

Over the last ten years, researchers have investigated the optimal FET platform as one-atom thick (0.7 nm) two-dimensional (2D) transition metal dichalcogenides (TMDs). However, since integration cannot be shown at the wafer scale, its practical uses are constrained.

The residues that develop during manufacturing are a significant issue. Polymethyl methacrylate (PMMA) is typically utilized as a holding support for transferring devices. Due to this substance’s notoriety for leaving insulating residues on TMD surfaces, the delicate TMD sheet is frequently mechanically damaged during transfer.

Other polymers that have been suggested as alternatives to PMMA include polydimethylsiloxane (PDMS), polyvinyl alcohol (PVA), polystyrene (PS), polycarbonate (PC), ethylene vinyl acetate (EVA), polyvinylpyrrolidone (PVP), and organic molecules like paraffin, cellulose acetate, and naphthalene. However, during transfer, residues and mechanical damage are inexorably introduced, which impairs the performance of FETs.

By effectively using polypropylene carbonate (PPC) for residue-free wet transfer, the IBS researchers were able to tackle this issue and achieve an unexpected breakthrough. PPC allows for the removal of residue as well as the creation of TMD at a wafer scale utilizing chemical vapor deposition.

Wrinkles, which develop during the transfer process, frequently appeared in earlier attempts to manufacture large-scale TMDs. Remainders and wrinkles were both removed by the PPC and TMD’s modest binding affinity.

The PPC transfer method we chose enables us to fabricate centimeter-scale TMDs. Previously, TMD was limited to being produced using a stamping method, which generates flakes that are only 30–40 μm in size.

Ashok Mondal, Study First Author, Institute for Basic Science

The researchers used a semimetal Bi contact electrode with a monolayer of MoS2, which was applied using the PPC technique, to construct an FET device. On the MoS2 layer, less than 0.08% of PPC residue was discovered to be present.

The device was discovered to have an ohmic contact resistance of RC ~78 Ω-µm, which is near to the quantum limit, due to the absence of interfacial residues. Using the h-BN substrate, it was also possible to produce a high on-current of 1.4 mA/µm and a very high current on/off ratio of ~1011 at 15 K.

This discovery was the first in the world to show wafer-scale TMD synthesis and transfer. Electrical characteristics of the innovative FET device created in this way were discovered to be significantly better than those of previously reported values. The current integrated circuit manufacturing technique is thought to make it simple to adopt this technology.

It is hoped that our success in the residue-free PPC transfer technique will encourage other researchers to develop further improvements in various TMD devices in the future.

Dr. Chandan Biswas, Study Co-Corresponding Author, Institute for Basic Science

Journal Reference:

Mondal, A., et al. (2023) Low Ohmic contact resistance and high on/off ratio in transition metal dichalcogenides field-effect transistors via residue-free transfer. Advanced Materials. doi:10.1038/s41565-023-01497-x