A method that can automatically identify and quantify materials’ microstructure from microscopic images has been developed by the research teams led by Professor Seungchul Lee of POSTECH and Dr. Se-Jong Kim and Dr. Juwon Na of the Materials Data Management Center in the Materials Digital Platform Division. The Ministry of Science and ICT oversees the government-funded research facility known as KIMS.

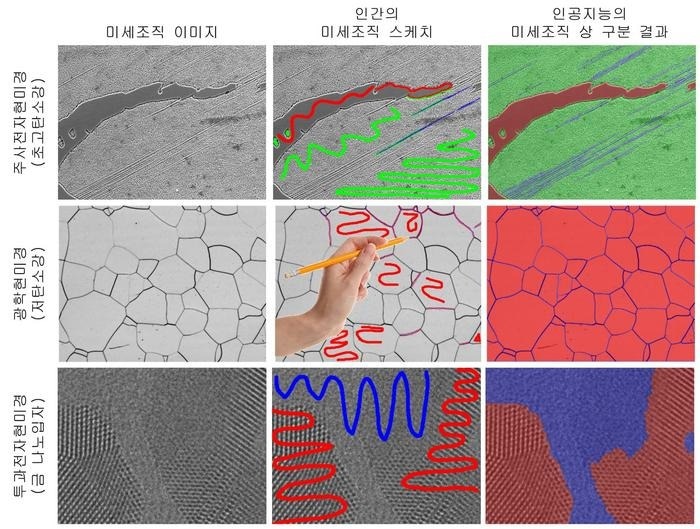

Microstructure segmentation based on human-AI collaboration. Image Credit: Korea Institute of Materials Science (KIMS)

Microstructure segmentation based on human-AI collaboration. Image Credit: Korea Institute of Materials Science (KIMS)

Multiple layers of material structure information, from the nanoscale to the mesoscale, are seen using microscopic imaging systems. The method of obtaining structural statistics from microscopic pictures is known as quantitative analysis of microstructure. However, there have been several constraints for humans or AI to do this on their own owing to the complexity and diversity of microstructure.

The research team has created an integrated framework for quantitative microstructure analysis by successfully fusing human and AI capabilities. Using just a single microstructure image and its related scribbling annotation by subject-matter experts, the AI model could segment microstructures.

To further enhance the performance and dependability of the model, the AI also actively engages in human interaction by asking experts to annotate scribbles. A variety of materials, microstructures, and microscopic imaging systems can all be utilized with the framework of human-AI collaboration, the study team's comprehensive trials have shown.

While earlier studies needed to collect a lot of dense annotation, this study significantly lowered the cost of annotation by employing scribble annotation, which can be quickly produced using a pen or mouse. The Automated Microstructure Quantitative Analysis System (TIMs) being created by KIMS will use this technology. It will be simple for common researchers to utilize as a result.

This study is the result of improving the existing subjective and time-consuming quantitative analysis of microstructure into an objective and automated process.

Dr. Juwon Na, Senior Researcher, Korea Institute of Materials Science

Professor Seungchul Lee of POSTECH, added, “Our framework that interacts with experts is expected to be widely used as a core analysis technology in industry and research, and through this, we expect to dramatically reduce the cost and time of new materials research and development and further significantly improve reliability.”

The Ministry of Science and ICT funded this study through the Korea Institute of Materials Science's basic project, the National Research Foundation of Korea’s mid-career researcher support project, and the Ministry of Trade, Industry, and Energy’s Alchemist project. On August 15th, 2023, the study findings were published in Acta Materialia (first author: Dr. Juwon Na), the most respected publication in the field of metallic materials.

Journal Reference:

Na, J., et al. (2023) A unified microstructure segmentation approach via human-in-the-loop machine learning. Acta Materialia. doi:10.1016/j.actamat.2023.119086