Zinc-air batteries have been under investigation for many years. Despite substantial research efforts, their commercialization has not significantly progressed. Recent research has successfully addressed certain challenges associated with the zinc-air battery cathode.

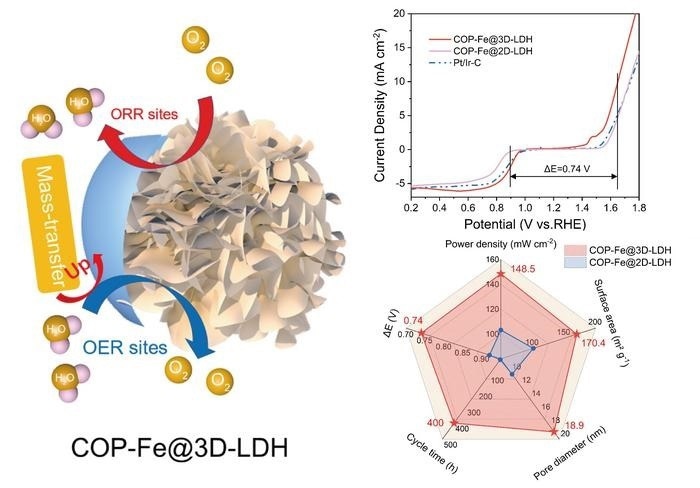

A Newly Hierarchically Porous Pyrolysis-Free Bifunctional Catalyst to Boost Ultralong Lifespan Zinc-Air Batteries. Image Credit: Zhonghua Xiang, Beijing University of Chemical Technology

The study was published on October 12, 2023, in the journal Energy Material Advances.

The development of cost-effective and high-performance zinc-air battery cathode catalyst is imperative. Currently, zinc-air batteries still not occupy the market, because they are limited in both stability and in their energy density.

Zhonghua Xiang, Study Author and Professor, Beijing University of Chemical Technology

Xiang detailed that zinc-air batteries exhibit limited operational capacity at high current densities due to numerous issues related to their cathode, anode, and electrolyte.

“The air cathode is critical to life span of ZABs. The construction of the three-phase (gas–liquid–solid) interface is the key to long life span ZABs,” Xiang notes.

In terms of kinetics, a three-phase reaction involving gas, liquid, and solid components takes place on the air cathode. To facilitate the Oxygen Reduction Reaction (ORR), it is essential to maintain a relatively hydrophobic environment and ensure an efficient gas diffusion pathway.

Over extended cycles, the ORR's active sites may become flooded, leading to reduced ORR activity and subsequent discharge decay. In contrast, the Oxygen Evolution Reaction (OER) catalyst requires super-hydrophilicity, which means the air cathode is more prone to flooding.

Furthermore, during OER, the generation of O2 bubbles can dislodge the catalyst. Therefore, it is crucial to ensure that the catalyst is securely attached to the electrode surface to prevent detachment.

When ZABs operate at high current densities, a substantial quantity of reactants, specifically O2, is needed to engage in the reaction. Therefore, it is imperative to have an air cathode with excellent substance transport pathways to ensure the efficient transportation of reactants.

Additionally, high-quality dual-function catalysts are of great importance in ZABs. A desirable ZAB catalyst should demonstrate exceptional ΔE (E10–E1/2) characteristics, outstanding stability under high current densities, a significant electrochemical-specific surface area, and an enriched pore structure.

These features collectively contribute to the battery's performance and reliability.

In conventional two-electrode ZABs, the air cathode relies on a bifunctional catalyst. This catalyst serves a dual purpose, functioning for both the Oxygen Reduction Reaction (ORR) and the Oxygen Evolution Reaction (OER).

While ORR and OER are reversible reactions, they occur with relatively high overpotentials. When ZABs operate at high voltage, particularly during OER, it can lead to a rapid decay in the activity of the ORR, which can have adverse effects on the battery's overall performance.

For efficient production of air cathode catalysts with superior performance. We creatively developed a pyrolysis-free strategy. The pyrolysis-free strategy can effectively avoid the structural reconfiguration during the pyrolysis process. In this paper, we make more hierarchically porous structures for pyrolysis-free catalysis, which efficient boost the transport of both reactant (O2) and product (H2O).

Zhonghua Xiang, Study Author and Professor, Beijing University of Chemical Technology

“Zinc-air batteries have been studied for decades, but, after a considerable amount of research, their commercialized is still not increase significantly,” Xiang adds. “To advance the field, we're turning to pyrolysis-free strategy. The pyrolysis-free strategy has overcome some issues of zinc-air battery cathode in recent research work, and similar work is also being carried out in our group.”

Journal Reference

Chen, T., et al. (2023). A Mass Transfer-Enhanced Bifunctional Catalyst to Boost Zinc-Air Batteries. Energy Material Advances. doi.org/10.34133/energymatadv.0061.