Domestic and industrial thermal management consumes a substantial amount of world energy. Maintaining the optimum temperature with little energy input is crucial from an economic and environmental standpoint. Air conditioning (AC) is commonly used to manage indoor thermal conditions. This uses a tremendous amount of energy. The global annual AC energy consumption is estimated to approach hundreds of billions of dollars by 2023.

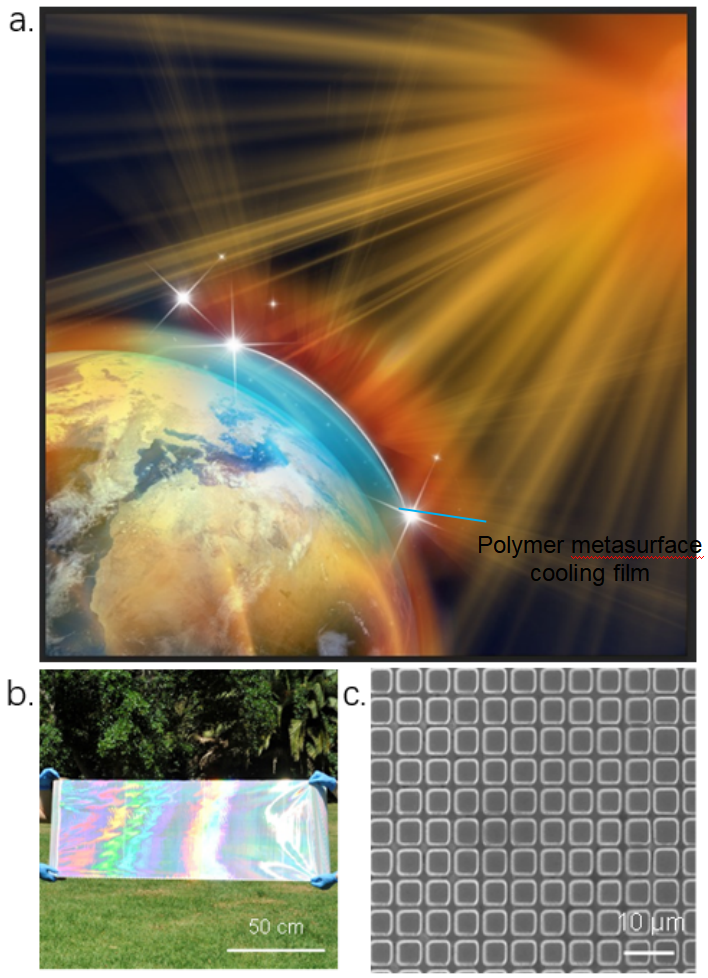

Concept and demonstration of polymer metasurface radiative cooling filma. Conceptual image of the large-scale polymer metasurface cooling film cool down the earth under sunlight. b. A photo of the large-scale and flexible polymer metasurface cooling film. c. An SEM image of the microstructures in the polymer metasurface cooling film. Image Credit: TranSpread

Concept and demonstration of polymer metasurface radiative cooling filma. Conceptual image of the large-scale polymer metasurface cooling film cool down the earth under sunlight. b. A photo of the large-scale and flexible polymer metasurface cooling film. c. An SEM image of the microstructures in the polymer metasurface cooling film. Image Credit: TranSpread

The continuous cooling requirements (24/7) of a growing number of huge data centers will exacerbate this sum. The severe economic load and deteriorating environment have created an urgent need for low-energy renewable cooling systems.

Researchers under the direction of Melbourne’s RMIT University's Professor Baohua Jia have created a roll-to-roll polymer film for enhanced radiative cooling, as reported in a new study published in eLight. The new method is based on a metasurface idea made possible by positioning three-dimensional trench-like structures inside the polymer film's thin layer.

Generally speaking, conventional heat dissipation uses more energy. Since it is the only technique that can send thermal radiation into space, radiant cooling has garnered much interest. This cools the object without using any energy. In the earth’s atmospheric transparency window, a radiative cooler with high emissivity would be optimal.

To keep from heating up in the sun, the radiative coolers should reflect a large amount of solar energy. High cooling performance thus depends on the capacity to correctly and flexibly alter spectra over a wide range, which is still a difficult task.

Three different forms of radiative cooling effects have been effectively proven. The three types—polymers, multilayer thin films, and metamaterials—are determined by the materials utilized and structural engineering techniques. Polymer films have been demonstrated to have several appealing features among these designs.

They are particularly promising for use in practical applications due to their low solar absorption, relatively good emissivity in the atmospheric transparency windows, low cost, and scalability.

However, they are severely constrained in their capacity to produce unity IR emissivity and solar reflectance at the desired broad bandwidth based solely on the intrinsic material absorption qualities without nanostructural modification. While spectral controllability can be enhanced by incorporating randomly distributed particles, a finely regulated spectrum is difficult to achieve.

Periodic structure metamaterials have shown exceptional spectral manipulation capacity for diurnal radiative cooling. However, metamaterial radiative coolers are based on rigid substrates with high thicknesses that cannot be combined with arbitrary-shaped items. Furthermore, due to fabrication problems, periodic micro/nanostructures are limited to small areas and thus unsuitable for real-world applications.

By creating periodic trench-like metasurface structures, the researchers were able to achieve exact spectrum modification in thin polymer materials. They were then created utilizing the environmentally beneficial roll-to-roll printing technology.

Almost all of the incident sunlight is reflected by the 50-m-thick polymer metasurface radiative cooling (PMRC) sheet. At the same time, it emits a lot of thermal radiation through the atmospheric transparency windows. This results in excellent cooling performance throughout the day.

The film is easily integrated into a variety of equipment, including a water tank, a COVID protective suit, and a car cover, and achieves great cooling performance. The large-scale roll-to-roll produced flexible PMRC film is cost-effective and easily attachable to any object for a wide range of cooling applications, fulfilling stringent cooling requirements while consuming no energy.

The PMRC film has omnidirectional absorption and emission and provides excellent cooling performance. It also has high flexibility, scalability, and stability, making it ideal for thermal management applications.

The Australia Research Council funded this study through the Discovery Project scheme (Grant No. DP190103186, DP220100603), the Industrial Transformation Training Centres scheme (Grant No. IC180100005), the Future Fellowship scheme (Grant No. FT210100806, No. FT220100559), the Discovery Early Career Researcher Award scheme (Grant No. DE230100383), the Suzhou Science and Technology Plan (Grant No. SYG202118) and the Natural Science Foundation of Shandong Province (Grant No. ZR2021ME162).

Journal Reference:

Lin, K.-T., et al. (2023) Highly efficient flexible structured metasurface by roll-to-roll printing for diurnal radiative cooling. eLight. doi:10.1186/s43593-023-00053-3