In the world of powder processing, understanding the permeability of powders is vital for a wide range of industries.

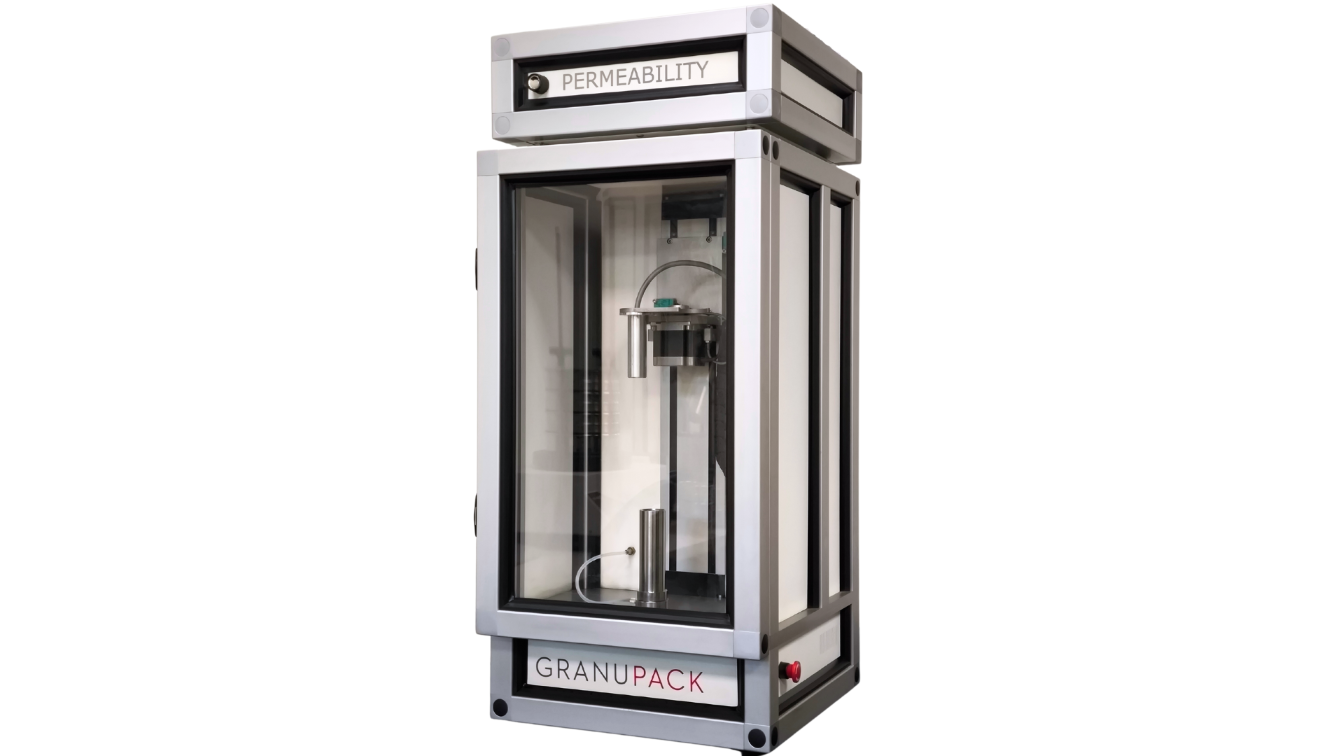

Whether it's pharmaceuticals, food production, or additive manufacturing, having a deep understanding of how powders behave under various packing conditions can dramatically impact product quality and production efficiency. That's where the GranuPack Permeability Unit comes into play. This innovative equipment is here to revolutionize the way we measure and utilize powder permeability.

Exploring the GranuPack Permeability Unit: A Game-Changer in Powder Permeability Measurement

The GranuPack Permeability Unit is a cutting-edge device designed for measuring the permeability of powders under different packing conditions. What sets it apart is its ability to provide detailed insights into how powders behave when subjected to varying levels of consolidation and density. Here's a closer look at the key components and features that make the GranuPack Permeability Unit a game-changer:

- Permeability Measurement Cell: At the heart of the GranuPack Permeability Unit lies the permeability measurement cell. This cell features a porous frit at its bottom, allowing air to pass through the powder sample. This design ensures precise and controlled measurements of permeability.

- Mass Flow Controller: The unit includes a mass flow controller that regulates the flow of air within the cell at controlled air flow rates. This precise control over the air flow is essential for accurate and repeatable measurements.

- Unique Measurement Technique: The GranuPack Permeability Unit employs a distinctive measurement technique. By alternating the application of taps to the powder with air insufflation through the powder bed, it is possible to measure the powder permeability at various packing fractions. This enables a comprehensive understanding of how powders behave under different conditions.

Unveiling the Key Features of the GranuPack Permeability

The GranuPack Permeability Unit boasts several key features that set it apart:

- Simultaneous Measurement of Permeability and Density: One of its most remarkable features is the ability to simultaneously measure both permeability and density. This dual measurement capability provides a more holistic view of powder behavior, allowing for improved process optimization.

- Measurement of Permeability at Low Consolidation: The unit excels in measuring permeability even at low consolidation levels. This is crucial for industries where maintaining powder flowability is essential, such as pharmaceuticals and food production.

- Measurement of Permeability in Static Conditions: Unlike some other methods that require fluidization, the GranuPack Permeability Unit can measure permeability in static conditions. This capability widens its application scope, making it more versatile and reliable.

What truly sets the GranuPack Permeability Unit apart is its ability to measure the permeability of a powder at different packing conditions. This unique capability empowers researchers and manufacturers to fine-tune their processes and ensure the consistent quality of their products.

Versatile Applications of the GranuPack Permeability Unit across Industries

The GranuPack Permeability Unit finds applications in various industries, including:

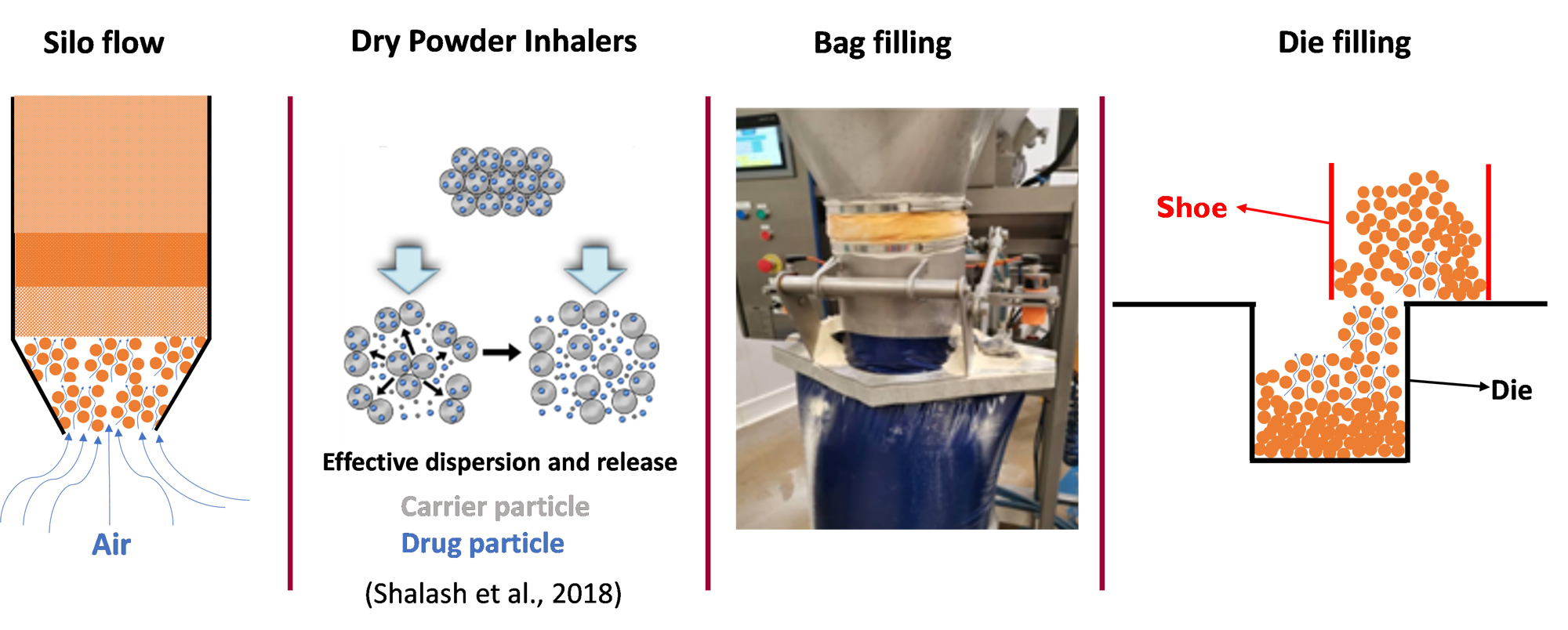

- Vertical Flow Inside a Silo: Understanding how powders behave in silos is essential for optimizing storage and flow in industries like agriculture and mining.

- Dry Powder Inhalers (DPI): The pharmaceutical industry benefits from precise measurements of powder permeability in DPIs, ensuring accurate drug delivery to patients.

- Bag Filling: Efficient bag filling requires knowledge of powder permeability to prevent clogs and ensure uniform filling.

- Die Filling: In manufacturing, die filling is crucial for producing consistent and high-quality products. The GranuPack Permeability Unit helps in optimizing this process.

Seamless Upgrade: Retrofitting the GranuPack Permeability Unit

For those who already own the GranuPack Classic, there's good news. The GranuPack Permeability Unit is retrofit-compatible with the GranuPack Classic and can be included in the All-In Maintenance Plan. This cost-effective solution allows you to upgrade your existing equipment and enhance your capabilities without the need for a complete overhaul.

Conclusion: A Bright Future for Powder Characterization

In conclusion, the GranuPack Permeability marks a significant advancement in the realm of powder processing and measurement. Offering thorough insights into powder behavior across various packing conditions, including low consolidation and static scenarios, it equips industries to enhance process efficiency, elevate product quality, and stay ahead in the competitive landscape.

The importance of measuring powder permeability cannot be overstated; permeability is one of the main driving mechanisms of powder processability (flowability, packing ability, compressibility, etc.) This underscores the critical need for precise measurement, making the GranuPack Permeability an indispensable tool for businesses aiming to optimize their operations.

Don't overlook the value of this innovative instrument for powder permeability analysis.

Reach out to us today to discover how the GranuPack Permeability can positively impact your operations and steer your business towards future success.