AMETEK Land, a world-leading manufacturer of highly accurate infrared pyrometers, scanners, and thermal imagers, is supporting industries including manufacturing, automotive, aerospace and construction with highly accurate and reliable temperature measurement solutions for induction and heat treating applications.

Image Credit: AMETEK Land

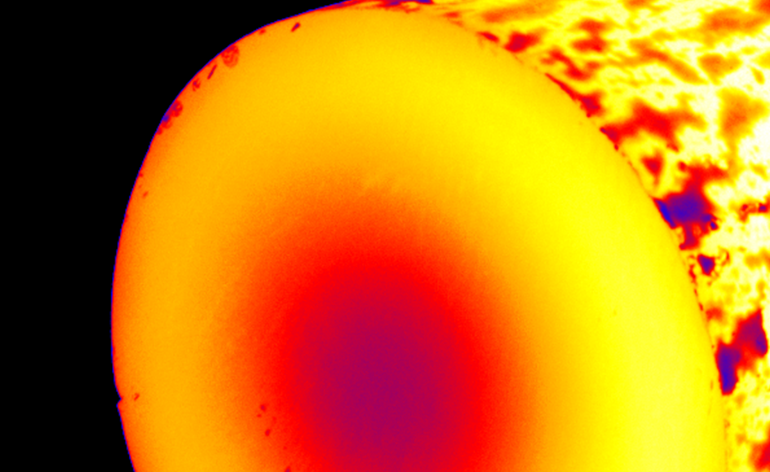

Induction heat treatment is a highly versatile technique widely used to alter the mechanical properties of materials including metals and alloys. However, accurate temperature control is crucial to achieve the desired temperature and material properties, and to control both the heating process and induction generator.

AMETEK Land offers a wide range of dedicated pyrometers, line scanners and thermal imagers to optimise these heating and processing applications.

One key solution is the SPOT+ range of pyrometers. These smart infrared pyrometers offer advanced industrial connectivity and visible light process video, making non-contact temperature measurements accurate and flexible, especially in the harshest of environmental conditions.

Thermal imaging cameras and systems also play an important role in industrial processing and furnace applications, forming a crucial component for visualising, controlling, and documenting the induction heating and heat treatment process.

LAND’s advanced cameras and systems, including the MWIR-640 and LWIR-640 imagers, and the NIR-2K, working with the IMAGEPro advanced processing and control software, help to meet the increasing demand for improved product quality, process efficiency, energy saving, predictive maintenance and emissions reduction.

Manfred Hayk, Global Infrared (IR) Product Manager - Product and Application Support said: “It can be challenging to obtain accurate temperature measurements in industrial processes. Our wide range of dedicated solutions are chosen by customers around the globe because of our proven technology and infrared temperature measurement experience, helping to provide controlled and precise measurements while optimizing process efficiency and increasing product quality.”