A single strand of fiber created at Washington State University possesses the electrical conductivity of a polymer called polyaniline and the flexibility of cotton.

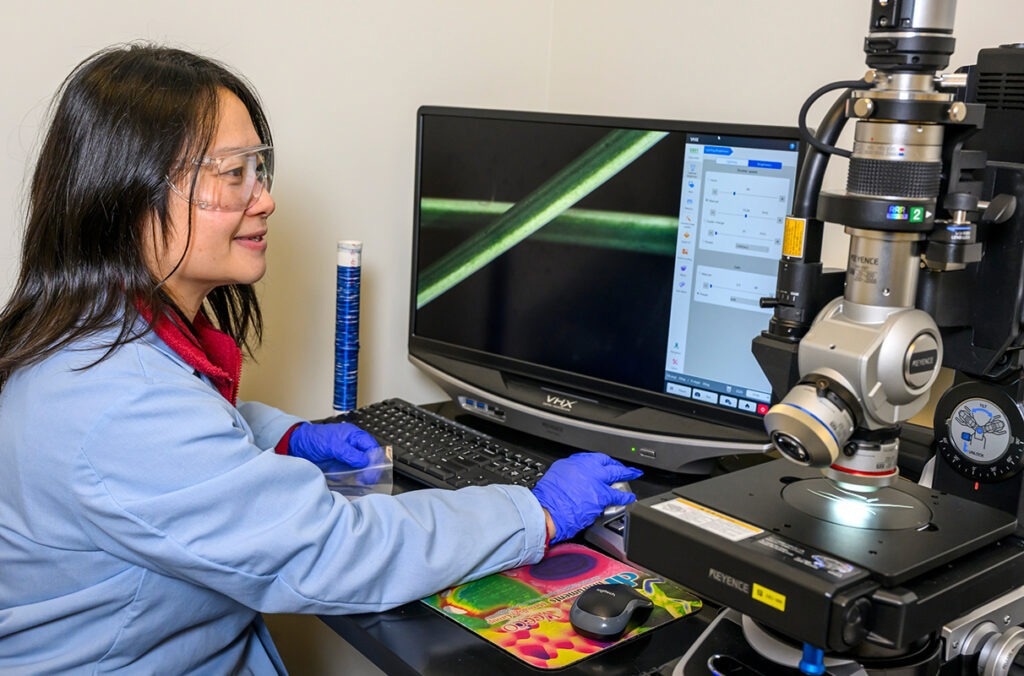

Washington State University textile researcher Hang Liu views a microscopic image of the newly developed fibers showing their side-by-side mix where one side is cotton and the other contains the polyaniline polymer that can carry an electric current. Image Credit: Dean Hare, WSU Photo Services

Washington State University textile researcher Hang Liu views a microscopic image of the newly developed fibers showing their side-by-side mix where one side is cotton and the other contains the polyaniline polymer that can carry an electric current. Image Credit: Dean Hare, WSU Photo Services

The recently created material has promising applications in wearable electronic fabrics. The WSU researchers evaluated the fibers using two different systems: one that monitored ammonia gas and another that powered an LED light. They published their results in the journal Carbohydrate Polymers.

We have one fiber in two sections: one section is the conventional cotton: flexible and strong enough for everyday use, and the other side is the conductive material. The cotton can support the conductive material which can provide the needed function.

Hang Liu, Corresponding Author, Textile Researcher, Washington State University

The objective is to use these fibers as flexible circuit sensor patches that can be integrated into clothing, albeit more research and development are required. These patches may be worn by soldiers, firefighters, or anyone handling chemicals as a part of their uniforms to check for potentially dangerous exposures. Exercise shirts with more functionality than existing fitness monitors are examples of further applications, as is health monitoring.

We have some smart wearables, like smart watches, that can track your movement and human vital signs, but we hope that in the future your everyday clothing can do these functions as well. Fashion is not just color and style, as a lot of people think about it: fashion is science.

Hang Liu, Corresponding Author, Textile Researcher, Washington State University

In this study, the WSU team attempted to solve the problems associated with combining the conductive polymer with cotton cellulose. Materials having very big molecules and repeating patterns are called polymers. Here, the researchers employed polyaniline, or PANI, a synthetic polymer with conductive qualities currently in use in producing printed circuit boards.

Although polyaniline is inherently conductive, it is brittle and cannot be processed into a textile fiber on its own. The WSU researchers used two different solutions to overcome this problem: one for the conductive polymer and another for the cotton cellulose from recycled t-shirts. After mixing these two solutions side by side, the mixture was extruded into a single fiber.

The outcome demonstrated strong interfacial bonding, which means that even after stretching and bending, the molecules from the various materials would remain together.

According to Liu, finding the ideal combination at the interface between cotton cellulose and polyaniline requires careful balancing.

Liu says, “We wanted these two solutions to work so that when the cotton and the conductive polymer contact each other they mix to a certain degree to kind of glue together, but we didn’t want them to mix too much, otherwise the conductivity would be reduced.”

WSU authors in this study included first author Wangcheng Liu as well as Zihui Zhao, Dan Liang, Wei-Hong Zhong, and Jinwen Zhang. The National Science Foundation and the Walmart Foundation Project supported the research.

Journal Reference:

Liu, W., et al. (2023). A novel structural design of cellulose-based conductive composite fibers for wearable e-textiles. Science Direct. doi/S0144861723007737