Using atomic-scale probing, researchers from Dresden University of Technology and the Helmholtz-Zentrum Dresden-Rossendorf have elucidated the process of water adsorption in certain microporous materials known as hierarchical metal-organic frameworks (MOFs).

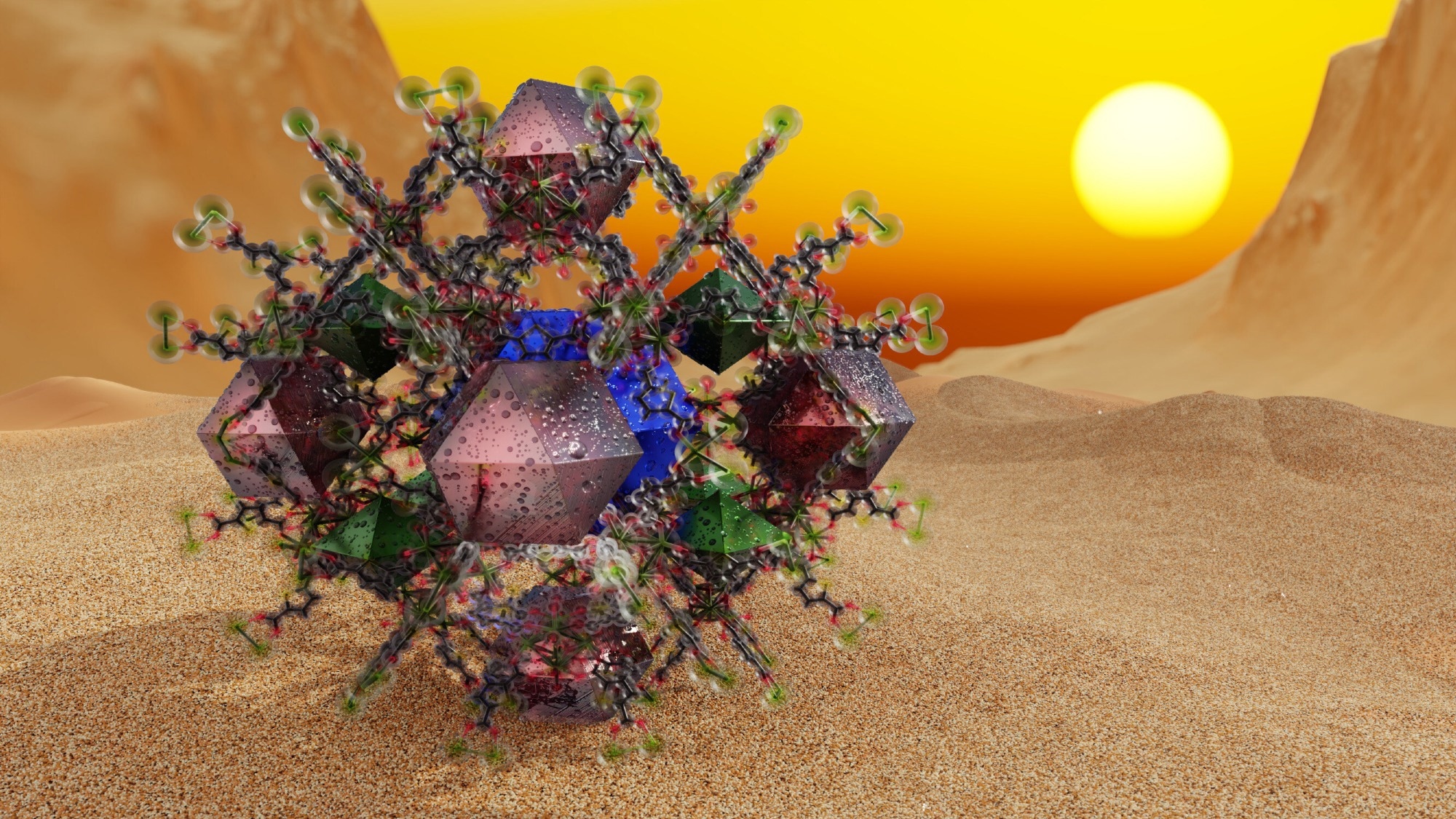

Metal-organic frameworks can adsorb water in the pores they form. Image Credit: B. Schröder/HZDR

Metal-organic frameworks can adsorb water in the pores they form. Image Credit: B. Schröder/HZDR

Their unique qualities, which were first discovered around 25 years ago, soon earned them the moniker “miracle materials”—it turned out that they could even extract water from the atmosphere. In ACS Applied Materials & Interfaces, the researchers explain how the material accomplishes this.

These very special materials are highly porous solids made of metals or metal-oxygen clusters which are connected in a modular way by pillars of organic chemicals. This 3D arrangement leads to networks of cavities reminiscent of the pores of a kitchen sponge. It is precisely these cavities that we are interested in.

Dr. Ahmed Attallah, Postdoctoral Researcher, Institute of Radiation Physics, Helmholtz-Zentrum Dresden-Rossendorf

These nanoscale pores serve as the basis for an endless array of possible uses, including water harvesting, catalysis, separation technology, gas storage, and innovative sensors, among many others.

Probing the Void

Using the same organic framework, the scientists synthesized two MOFs based on the metals hafnium and zirconium. Then, using a range of complementary approaches, the scientists took a closer look at the properties of the resulting materials.

They ascertained the maximum amount of water vapor or nitrogen that could be held inside the material’s pores. However, they also examined the mechanism of water adsorption in MOFs in greater detail, which was not known at the time.

To shed light on the process, we used a non-destructive technique known as positron annihilation lifetime spectroscopy, or in short, PALS, in which a positron will interact with electrons—its antiparticles—thereby annihilating, and then releasing gamma rays that can be detected.

Dr. Andreas Wagner, Head, ELBE Center for High-Power Radiation Source, Helmholtz-Zentrum Dresden-Rossendorf

He added, “The time between the emission of positrons stemming from a radioactive source and the subsequent detection of gamma rays is the positrons’ lifetime. This in turn depends on how fast they meet electrons.”

When a material contains voids such as nanopores, electrons and positrons combine to form what is known as positronium atoms. These atoms consist of one electron and one positron, and they orbit around their shared center of mass, heading straight toward one another until one of the two particles is annihilated or scattered, depending on which happens first.

These unusual atoms provide information about the size and spread of the vacuum because they survive longer in larger voids. The scientists discovered that a step-by-step filling mechanism, which included the creation of liquid bridges in the pores, primarily controlled the water adsorption in the MOFs. The development of water clusters on the pore surface, which produced tiny air gaps in the pores, had an impact on water adsorption.

Squeezing Out Desert Air

Due to the close chemical resemblance of the metals zirconium and hafnium, the resulting metal-organic frameworks have the exact same pore sizes and high chemical stability, allowing us evaluating the validity of our method at the same time.

Stefan Kaskel, Chair of Inorganic Chemistry I, Dresden University of Technology

The creation of innovative functional materials for a range of functions, including water adsorption, environmental catalysis, and energy storage and conversion, is the main emphasis of his group’s research.

Based on the findings, the researchers draw the conclusion that their research offers fresh perspectives on the mechanism of water adsorption in hierarchical MOFs, which could help in the development of more effective materials for air-to-water harvesting—a crucial process in dry areas. MOFs can absorb water molecules from the atmosphere by subjecting them to air. The water can then be freed and used by heating the mixture or lowering the pressure.

The scientists are already planning ahead: Can this technology be used to create commercial solutions? According to data from another team in the field, the present realistic feasible yield could be estimated using 1.3 liters of water per kilogram of MOF per day from arid air.

However, consideration of additional elements beyond yield is required to get an overall sustainable solution.

Kaskel and Attallah stated, “To scale up the water harvesting with MOFs, they should be cheaply accessible in large quantities. Besides, traditional synthesis routes require large amounts of organic solvents or the acquisition of expensive building blocks.”

To prevent these, freshly developed “green” synthesis processes will gain traction in the future, assuring eco-friendly MOF production.

The Dresden team is already adopting green chemistry concepts, such as using water as a solvent, running processes at low temperatures to save energy, and using waste materials as supplies of metals and organic linkers.

Journal Reference:

Attallah, A. G., et. al. (2023) Unravelling the Water Adsorption Mechanism in Hierarchical MOFs: Insights from In Situ Positron Annihilation Lifetime Studies. ACS Applied Materials & Interfaces. doi:10.1021/acsami.3c10974.