Is it feasible to produce tissue in a lab to replace damaged cartilage, for example? With the use of a procedure that is quite distinct from previous approaches employed globally, TU Wien (Vienna) has now made substantial progress toward producing replacement tissue in the lab.

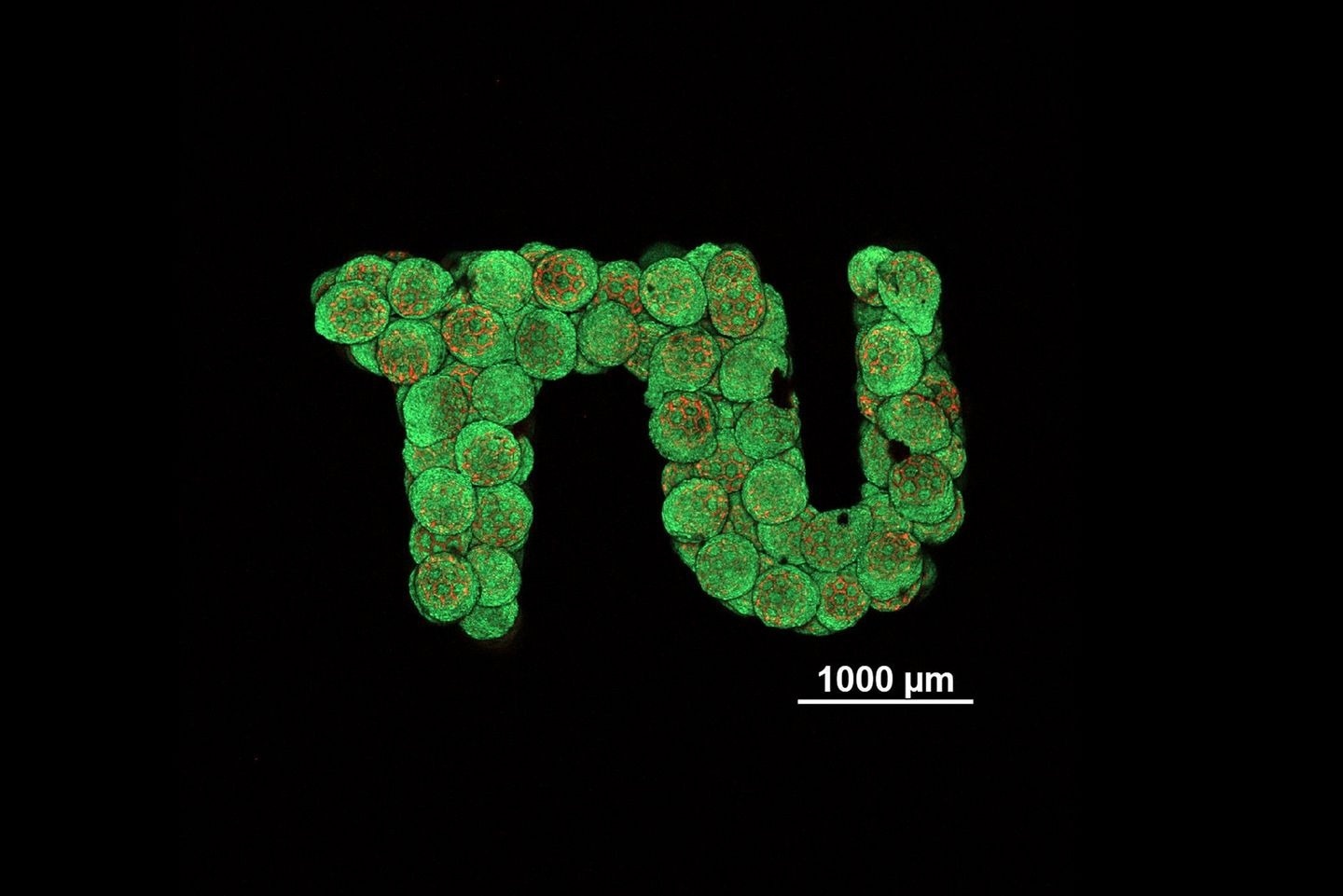

The spheroids in which living cells are grown, can be assembled into almost any shape. Image Credit: TU Wien

The spheroids in which living cells are grown, can be assembled into almost any shape. Image Credit: TU Wien

The small, porous spheres comprised of biocompatible and biodegradable plastic are created using a unique high-resolution 3D printing technique, and they are then colonized with cells. After that, these spheroids can be placed in any shape, and the cells from the various units blend to create a consistent, living tissue. The notion has now been demonstrated at TU Wien with cartilage tissue, which was previously thought to be particularly difficult in this regard.

Cultivating cartilage cells from stem cells is not the biggest challenge. The main problem is that you usually have little control over the shape of the resulting tissue. This is also due to the fact that such stem cell clumps change their shape over time and often shrink.

Oliver Kopinski-Grünwald, Study Author and PhD Student, TU Wien

A novel method is being employed by the TU Wien research team to avoid this: tiny cage-like structures with a diameter of only 0.3 millimeters are produced using specifically designed laser-based high-resolution 3D printing machines. These structures resemble miniature footballs. Compact construction blocks that can be constructed into any shape are formed by them, and they also act as a support framework.

These football-shaped mini-cages are initially filled with stem cells, which soon fill the tiny space.

In this way, we can reliably produce tissue elements in which the cells are evenly distributed and the cell density is very high. This would not have been possible with previous approaches.

Aleksandr Ovsianikov, Professor and Head, 3D Printing and Biofabrication Research Group, TU Wien

Growing Together Perfectly

The group made use of differentiated stem cells, which are stem cells that are preprogrammed to create a certain type of tissue, in this case, cartilage tissue, rather than stem cells that can no longer grow into any other type of tissue.

These cells are especially intriguing for medicinal applications; nonetheless, cartilage cells provide a challenge in terms of constructing larger tissue. Extracellular matrix, a structure resembling a mesh formed by the cells in cartilage tissue, is highly evident and frequently inhibits the proper growth of distinct cell spheroids together.

The 3D-printed porous spheroids can be assembled into any provided the appropriate cells are colonized within them. Now, the important question is: do the cells from various spheroids also mix together to produce a consistent, homogenous tissue?

Kopinski-Grünwald added, “This is exactly what we have now been able to show for the first time. Under the microscope, you can see very clearly: neighboring spheroids grow together, the cells migrate from one spheroid to the other and vice versa, they connect seamlessly and result in a closed structure without any cavities - in contrast to other methods that have been used so far, in which visible interfaces remain between neighboring cell clumps.”

While the tissue is still maturing, the small 3D-printed scaffolds provide mechanical support to the entire structure. After a few months, the plastic structures break down and eventually vanish, leaving the completed tissue in the desired form.

First Step Towards Medical Application

The novel method might potentially be used to customize several larger tissues, including bone tissue, and is not just restricted to cartilage tissue. There are still some challenges to be resolved, though, since for these tissues to grow larger than a specific size, blood vessels would also need to be included, unlike in cartilage tissue.

Kopinski-Grünwald concluded, “An initial goal would be to produce small, tailor-made pieces of cartilage tissue that can be inserted into existing cartilage material after an injury. In any case, we have now been able to show that our method for producing cartilage tissue using spherical micro-scaffolds works in principle and has decisive advantages over other technologies.”

Journal Reference:

Kopinski-Grünwald, O., et. al. (2024) Scaffolded spheroids as building blocks for bottom-up cartilage tissue engineering show enhanced bioassembly dynamics. Acta Biomaterialia. doi:10.1016/j.actbio.2023.12.001.