Panacol presents its first series of new, UV curable, black epoxy resin adhesives. These “Black&Light” adhesives, Vitralit® BL UC 1101, Vitralit® BL UC 1102 and Vitralit® BL UC 1103, can be cured in thicker layers using only UV light, eliminating the need for a secondary curing mechanism. Another major benefit from those Black&Light adhesives is room temperature shipping and storage. Conventional single-component, black-colored epoxy adhesives must be transported and stored cold or deep-frozen.

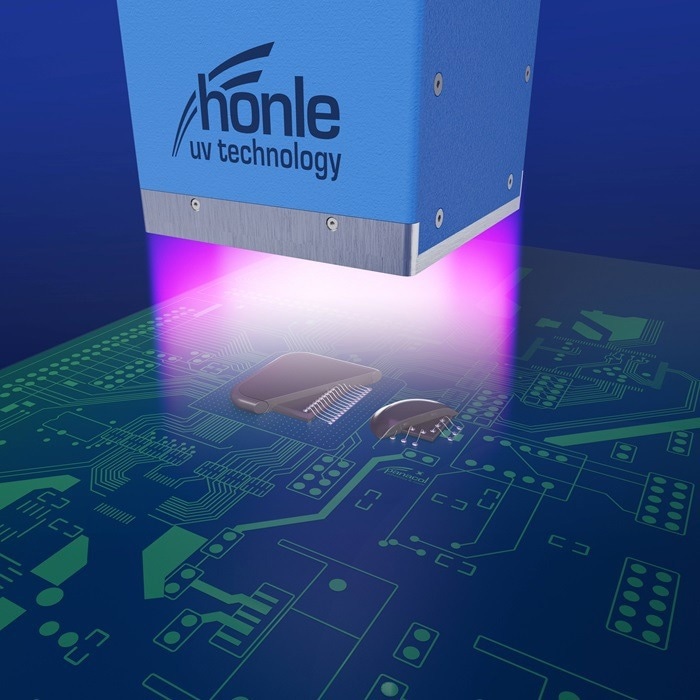

Black epoxies are being cured with UV LED light. Image Credit: Panacol

Black epoxies are being cured with UV LED light. Image Credit: Panacol

The black color in a conventional UV adhesive absorbs a high percentage of the UV curing energy. This means that the UV light energy required to fully polymerize an adhesive only penetrates a few micrometers. This phenomenon leads to the formation of a superficial “skin”, while the adhesive underneath remains uncured. The new black Vitralit® BL UC adhesives from Panacol can be cured to greater than 1mm in thickness, purely with UV LED light. UV LED curing systems from Dr. Hönle are perfectly matched to the absorption wavelengths of the Black&Light technology, ensuring optimal curing of the black adhesives.

Vitralit® BL UC 1101, Vitralit® BL UC 1102, and Vitralit® BL UC 1103 are Panacol’s new Black&Light adhesives and they cover a wide range of applications. They are suitable for component encapsulation, glob top, or edge bonding in electronics production. They can also be used as optical adhesives in applications requiring high OD (optical density) values.

Vitralit® BL UC 1101 is the perfect choice if a thick layer of adhesive is needed. It cures reliably in thick layers up to 1.3 mm, resulting in an optical density of up to 3.9. If a high optical density in lower layer thickness is needed, Vitralit® BL UC 1103 with OD values of up to 6 is the best option. In optoelectronic component assembly, Vitralit® BL UC adhesives minimize reflections and can safeguard the sensitive transmission values required for automotive sensors.

All three new adhesives offer outstanding mechanical properties including high glass transition temperatures, low shrinkage, and low coefficient of thermal expansion. Those characteristics ensure reliable bonding results with an excellent thermal and positioning stability. As the Black&Light technology is compatible with many Vitralit® epoxy resin adhesives from Panacol, individual adhesive solutions matching specific curing conditions and/or mechanical properties are possible.