From KICReviewed by Lexie CornerMar 14 2024

KIC, a renowned pioneer in thermal process and temperature measurement solutions for electronics manufacturing, is excited to announce its participation in the 2024 IPC APEX EXPO, scheduled to take place April 9-11, 2024, at the Anaheim Convention Center in California. Visit KIC at Booth 1626 to witness the latest advancements in reflow process inspection (RPI) technology.

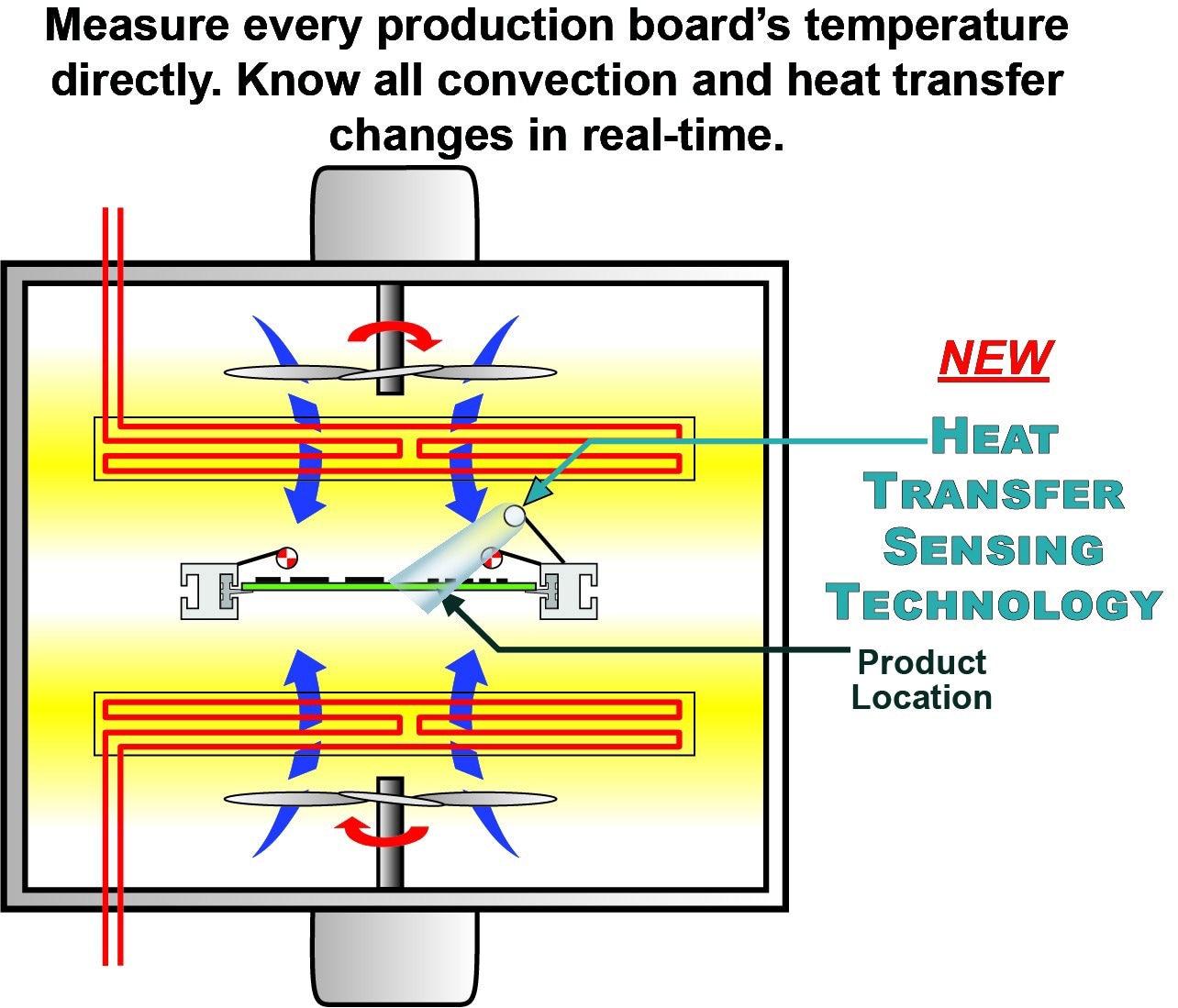

Image Credit: KIC

In response to the dynamic demands of today's manufacturing environment, where maintaining the highest level of quality and process control is paramount, KIC proudly introduces NEW SENSOR TECHNOLOGY. This groundbreaking technology, Contact-less Thermal AnalysisTM, directly measures board temperatures during production, marking a revolutionary advancement in electronics manufacturing.

Contact-less Thermal AnalysisTM: KIC’s revolutionary Contact-less Thermal AnalysisTM directly measures board temperature at the end of the heated section of the reflow oven during production. This capability enables real-time monitoring of temperature and convection changes, representing a monumental leap in reflow process inspection technology.

Benefits of the New Sensing Technology:

- Precision Redefined: Directly measuring board temperature and heat transfer changes ensures unparalleled precision and quality in reflow profiles, monitoring all aspects of the oven's influence on production boards.

- Combined Board-Level Temperatures: KIC RPI employs advanced algorithms, considering board temperature and ambient temperature at the board level, to determine temperature, time, and convection changes impacting the reflow profile.

- Seamless Integration: The RPI system actively tracks process Cpk, providing critical temperature profile data that seamlessly integrates with other MES factory automation systems, SPI, and AOI data.

Experience the Future of Electronics Manufacturing: Discover the future of electronics manufacturing with KIC's advanced RPI systems equipped with Contact-less Thermal AnalysisTM. Stay ahead of the competition, enhance process efficiency, and ensure uncompromised quality in every PCB.

Ready to Elevate Your Manufacturing Quality and Process Control?

Visit KIC at the 2024 IPC APEX EXPO to engage with thermal process experts, learn more about this groundbreaking technology, and explore solutions for soldering and curing processes in electronics manufacturing and semiconductor advanced packaging.