Reviewed by Lexie CornerApr 23 2024

In a recent paper published in the Journal of Chemical Engineering Journal, researchers from the Korea Institute of Science and Technology announced that they have created a technology that uses textile materials to selectively recover high-purity gold from electrical and electronic waste containing different metals.

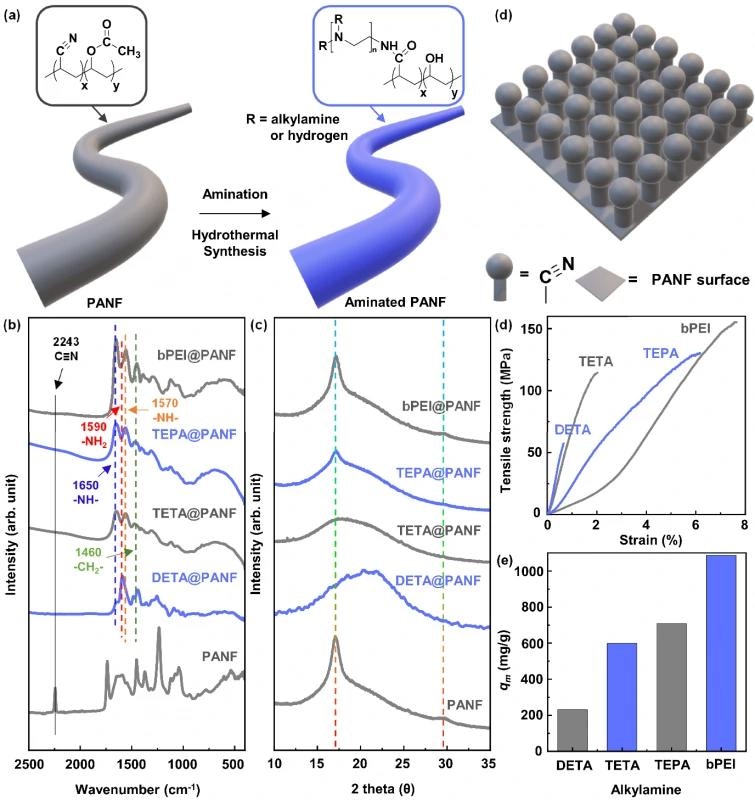

Preparation and physicochemical characteristics of the aminated polyacrylonitrile fibers (PANFs). Representative illustrations of PANF (a) before and after coupling reaction of various alkylamine molecules. Different colors of PANF and amine-laden polymeric fiber (ALPF) represent different functional groups of nitrile and alkylamines. (b) FT-IR spectra of PANF before and after coupling reaction of different alkylamines using diethylenetriamine (DETA), triethylenetetramine (TETA), tetraethylenepentamine (TEPA), and branched poly(ethyleneimine) (bPEI). (c) XRD patterns of the PANF and aminated PANFs. (d) Stress-strain curves of the PANF and aminated PANFs. (e) Maximum adsorption capacity (qm) of the aminated PANFs for Au(III) ions. Initial concentration (Ci) and pH value of the Au solution were 1000 mg/L and 1, respectively. Contact time (t, min) between the adsorbent and Au solution was set to 24 hours, and the adsorbent dose was 0.5 g/L. Image Credit: Korea Institute of Science and Technology

Preparation and physicochemical characteristics of the aminated polyacrylonitrile fibers (PANFs). Representative illustrations of PANF (a) before and after coupling reaction of various alkylamine molecules. Different colors of PANF and amine-laden polymeric fiber (ALPF) represent different functional groups of nitrile and alkylamines. (b) FT-IR spectra of PANF before and after coupling reaction of different alkylamines using diethylenetriamine (DETA), triethylenetetramine (TETA), tetraethylenepentamine (TEPA), and branched poly(ethyleneimine) (bPEI). (c) XRD patterns of the PANF and aminated PANFs. (d) Stress-strain curves of the PANF and aminated PANFs. (e) Maximum adsorption capacity (qm) of the aminated PANFs for Au(III) ions. Initial concentration (Ci) and pH value of the Au solution were 1000 mg/L and 1, respectively. Contact time (t, min) between the adsorbent and Au solution was set to 24 hours, and the adsorbent dose was 0.5 g/L. Image Credit: Korea Institute of Science and Technology

The majority of Korea's metal resources are imported; however, in light of resource depletion and growing raw material costs, “circular resources,” or recycled waste metal resources, have surfaced in recent years.

As a result, SK hynix has devised a medium—to long-term plan to raise the amount of waste produced during the semiconductor manufacturing process that is recovered and reused to over 30 % by 2030. Similarly, Samsung Electronics is coordinating a used mobile phone collection program with the non-profit organization E-circulation Governance. It is anticipated that the size of the global circular economy market will more than double, from $338 billion in 2022 to $712 billion in 2026.

In this context, a group headed by Dr. Jae-Woo Choi from the Water Resource Cycle Research Center, Korea Institute of Science and Technology (KIST) announced that they have created a technology that uses textile materials to selectively recover high-purity gold from electrical and electronic waste that contains different metals.

Typically, granular adsorbents are used for metal recovery because their high specific surface area makes them more efficient at adsorption. However, these adsorbents can be challenging to manage underwater, leading to poor recovery rates and even secondary environmental contamination.

However, materials that resemble fibers have a great deal of potential for industrial use because they are simple to manipulate underwater and can be woven into a variety of shapes. When gold recovery is applied to the support, they are easily broken because of their low strength and thin thickness.

To enhance the molecular gold recovery performance and structural stability of polyacrylonitrile (PANF) fibers, KIST researchers have chemically immobilized alkaline molecules on their surfaces. Compared to the team's earlier developed granular gold adsorption material, the amine-containing polymer fiber can improve the adsorption performance of gold ions (Au) in waste by up to 2.5 times (from 576 mg/g to 1,462 mg/g) due to its significantly larger surface area.

The developed fibrous adsorbent achieved a gold recovery efficiency close to 100 % in a wide range of pH 1-4, including most waste liquids. It demonstrated a gold recovery efficiency of more than 99.9 % in solutions obtained by leaching real CPUs. The fact that only gold ions (with a high purity of more than 99.9 %) can be extracted from the solution while 14 other metal ions are also present is especially remarkable. Even after ten uses, the gold recovery rate remained 91 %, indicating outstanding reusability.

By enabling efficient and eco-friendly metal resource recovery, the fiber-type adsorbent developed by KIST can reduce Korea's dependence on resource imports and prepare for the risk of rising raw material prices. We plan to expand the scope of future research to selectively recover various target metals in addition to gold, said Dr. Youngkyun Jung.

Dr. Jae-Woo Choi, Study Head, Water Resource Cycle Research Center, Korea Institute of Science and Technology

Journal Reference:

Jung, Y., et al. (2024) Efficient and selective gold recovery using amine-laden polymeric fibers synthesized by a steric hindrance strategy. Chemical Engineering Journal. doi.org/10.1016/j.cej.2024.149602