From AIMPLASReviewed by Lexie CornerApr 26 2024

AIMPLAS, the Plastics Technology Centre, has developed more than 2,000 sacks for food and basic necessities for the International Committee of the Red Cross (ICRC). These sacks are more sustainable and durable because they contain additives in multilayer structures based on raffia fabric that extend the life of the sacks, thus making them more sustainable in some cases thanks to the use of recycled material.

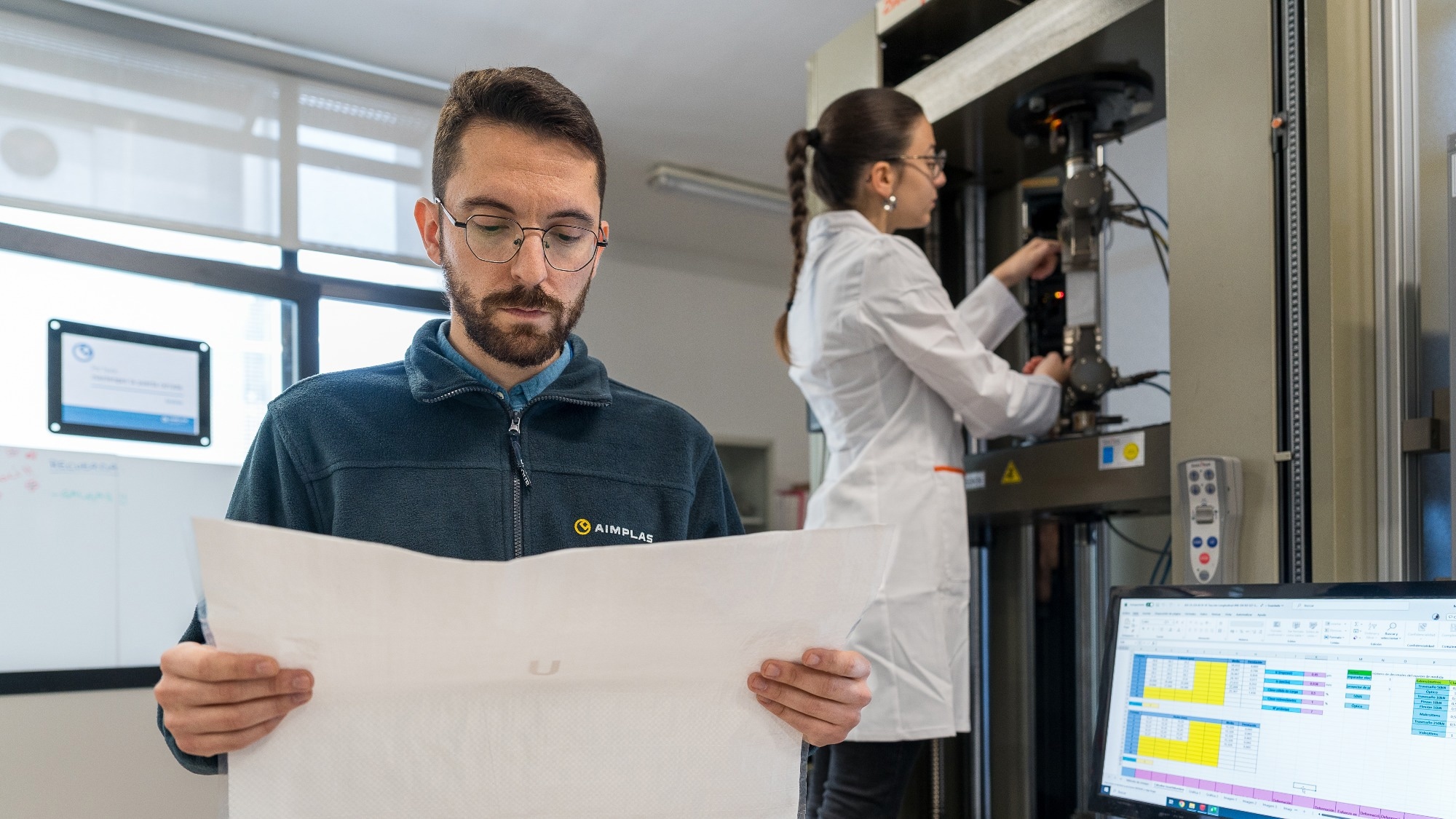

Image Credit: AIMPLAS

This action is part of a project funded by Innovation Norway and led by the ICRC, the United Nations High Commissioner for Refugees (UNHCR) and the UN World Food Programme (WFP). The aim of this project is to do research on innovative alternatives and solutions for sacks made of woven polypropylene that are used for packaging food and relief items. The project is managed by dss+, a sustainability consulting firm, and governed by a Steering Committee made up of representatives from the three humanitarian organizations (ICRC, UNHCR and WFP), Innovation Norway and the Norwegian Red Cross.

AIMPLAS contributed to the project by designing a multilayer structure based on polypropylene that makes use of evaluated formulations that improve sack performance. These developments were applied in more than 1,500 sacks for transporting wheat flour and dried beans with the aim of delaying sack degradation due to exposure to extreme environmental conditions. The plastics technology centre also formulated a second coating, which also contains recycled material and was used to make a further 500 sacks for blankets.

Rafia Industrial S.A, from the Spanish Armando Álvarez group, has collaborated in the project together with AIMPLAS, specifically in the production of raffia sacks on an industrial scale, providing different types of bags to the different locations established within the project framework.

The Sacks Will Be Field-Tested in Cameroon, India and Turkey

These humanitarian aid sacks will be included in three supply chains selected by the organizations involved for field-testing in diverse, changing environments in the challenging context of humanitarian work. The sacks designed by AIMPLAS will be used in Cameroon, India and Turkey.

Also participating in this project are AUST, a university in Bangladesh whose Textile Engineering Department will develop a jute sack with a biopolymer coating; and Giotto & SUPSI, a consortium made up of a Swiss consultancy and a Swiss university that is working on the development of a natural fibre-based material treated using a layer-by-layer approach.

The project consortium will also carry out field-testing involving a life cycle assessment of polypropylene sacks and their alternatives to analyse the reality in the field and compare these new solutions with the original sacks in a context as realistic as possible.