Researchers from Tsinghua University Press have elucidated how CrTaO4 enhances the oxidation resistance of high-entropy alloys containing chromium and tantalum. They suggest that CrTaO4 holds significant promise as an innovative material for high-temperature thermal barrier applications. The study has been published in the Journal Advanced Ceramics.

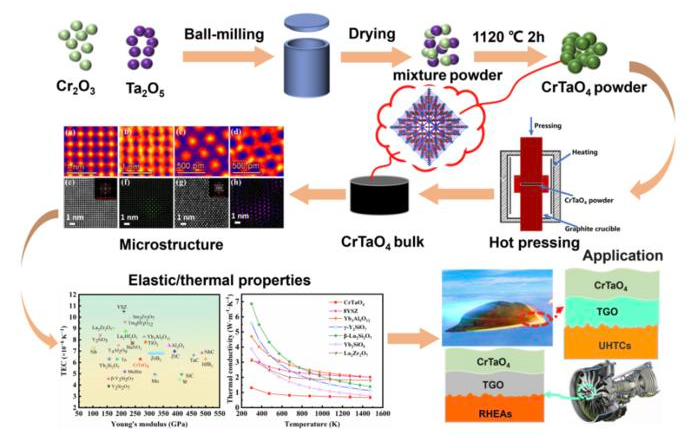

The CrTaO4 powder and bulk CrTaO4 were synthesized by solid state reaction and hot-press sintering, respectively. Using HAADF and ABF-STEM techniques, the rutile crystal structure of CrTaO4 was confirmed and short-range order was directly observed. Intriguingly, on the ground of moderate thermal expansion coefficient, low thermal conductivity, CrTaO4 is expected a new thermal barrier material for refractory metals and their alloys, refractory high entropy alloys, and ultrahigh temperature ceramics. Image Credit: Journal of Advanced Ceramics, Tsinghua University Press

For many years, the quest for novel materials that surpass the temperature capability of nickel-based superalloys has fascinated materials scientists. Refractory metals (RM) and their alloys are the preferred materials for this use due to their high melting points, solidus temperatures, and elevated temperature strength.

The primary drawback hindering their application in oxygen-rich environments is poor oxidation resistance. This is attributed to the formation of porous, rapidly growing, or volatile oxides. Due to the large composition space that has been opened up, the recently introduced new design paradigm of high-entropy alloys has made it possible to overcome this shortcoming.

Notably, some RHEAs show exceptional mechanical properties above 1200 °C in addition to good oxidation resistance, as demonstrated by the formation of either the rarely encountered complex oxide CrTaO4 or the well-known protective scale Al2O3. The protective complex oxide CrTaO4 has not yet had its mechanical and thermal properties examined despite the abundance of reports on the oxidation behavior of RHEAs. Since this complex oxide has been disregarded for many years, it is crucial to close this research gap.

The synthesis, microstructure, elastic/mechanical properties (hardness, flexural strength, and fracture toughness), and thermal properties (melting point, Debye temperature, anisotropic thermal expansion coefficients, and thermal conductivity) of bulk CrTaO4 were first reported by a group of material scientists led by Yanchun Zhou from Zhengzhou University in China.

In this report, we synthesized phase-pure CrTaO4 powder by the solid-state reaction between Cr2O3 and Ta2O5. Then, near fully dense bulk CrTaO4 was prepared by hot-press sintering the CrTaO4 powders. The grains are well crystallized with average equiaxed grain size of 2.07±0.73 μm and well faceted shapes. Using HAADF and ABF-STEM techniques, the rutile crystal structure of CrTaO4 was confirmed and short-range order was directly observed.

Yanchun Zhou, Professor, School of Materials Science and Engineering, Zhengzhou University

Zhou is a Senior Expert whose research interests focus on the field of high-temperature ceramics material.

CrTaO4 has been unexpectedly found to play a decisive role in improving the oxidation resistance of Cr and Ta-containing RHEAs. However, the mechanical and thermal properties of CrTaO4 have not been reported. For a new material, it is necessary to explore its properties.

Yanchun Zhou, Professor, School of Materials Science and Engineering, Zhengzhou University

CrTaO4 showcases elastic and mechanical characteristics akin to yttria-stabilized zirconia (YSZ). It boasts Young’s modulus, shear modulus, and bulk modulus of 268, 107, and 181 GPa, correspondingly. Additionally, its Vickers hardness, flexural strength, and fracture toughness measure at 12.2 ± 0.44 GPa, 142 ± 14 MPa, and 1.87 ± 0.074 MPa·m1/2.

“The analogous elastic/mechanical properties of CrTaO4 to those of YSZ has spurred inquiries to lucrative leverage it as a new thermal barrier material,” said Yanchun Zhou.

CrTaO4 has a melting point of 2103 ± 20 K. With an average TEC of (6.39 ± 0.11) × 0−6 K−1, the anisotropic thermal expansion coefficients (TECs) are αa = (5.68 ± 0.10) × 10−6 K−1 and αc = (7.81 ± 0.11) × 10−6 K−1. CrTaO4 has a thermal conductivity of 1.31 W·m−1·K−1 at room temperature and 0.66 W·m−1·K−1 at 1473 K, which is lower than that of the majority of the thermal barrier materials that are currently in use.

From the perspective of matched thermal expansion coefficient, CrTaO4 pertains to an eligible thermal barrier material for refractory metals and ultrahigh temperature ceramics.

Yanchun Zhou, Professor, School of Materials Science and Engineering, Zhengzhou University

More careful investigation is still required to determine whether CrTaO4 is a suitable alternative for a heat barrier. Zhou also proposed five main research directions that could be investigated in the future: CMAS resistance, water vapor resistance, coating deposition techniques, stability during plasma deposition, and thermal/structural stability of the coatings during operation.

Additional contributors to this work include Xiaohui Wang and Chao Zhang from the Institute of Metal Research at the Chinese Academy of Sciences in Shenyang, China; Yingwei Li from the School of Civil Engineering at Wuhan University in Wuhan, China; and Shuang Zhang, Huimin Xiang, Cheng Fang, Mingliang Li, and Hailong Wang from the School of Materials Science and Engineering at Zhengzhou University in Henan, China.

This research was funded by the National Natural Science Foundation of China.

Journal Reference:

Zhang, S., et al. (2024) Microstructure, elastic/mechanical and thermal properties of CrTaO4: A new thermal barrier material? Journal of Advanced Ceramics. doi.org/10.26599/JAC.2024.9220862.